Coal water slurry, preparation method thereof and preparation method of synthesis gas

A technology for coal-water slurry and synthesis gas, which is applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of low yield of coal-water slurry synthesis gas, uneven particle size distribution, and low slurry concentration, and achieves the realization of The effect of resource utilization, uniform particle size distribution and high slurry concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

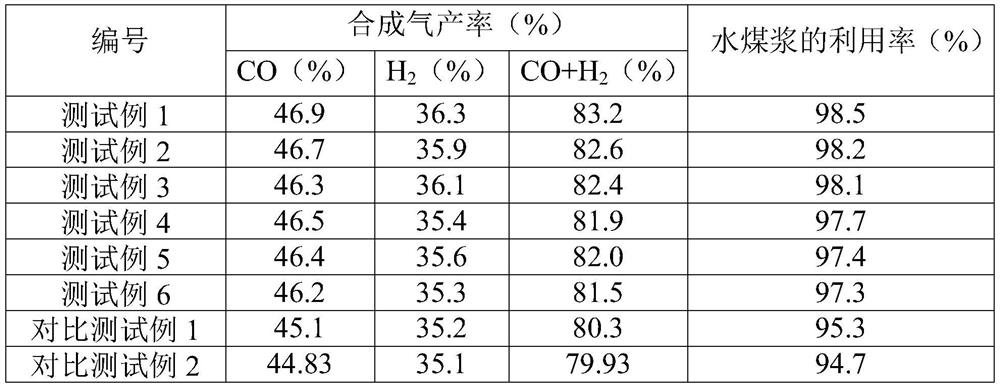

Examples

preparation example Construction

[0012] As mentioned above, the first aspect of the present invention provides a method for preparing coal-water slurry, the method comprising: adjusting the pH value of the MTP process wastewater to greater than 8, then mixing with chemical additives and water to obtain a slurry; The slurry is mixed and ground with coal and waste MTP catalyst to obtain coal water slurry. The mixing in the present invention can be carried out under stirring conditions.

[0013] In some embodiments of the present invention, preferably, the pH value of the MTP process wastewater is adjusted to 8-9, which is more conducive to the preparation of better-performing coal-water slurry.

[0014] In the present invention, the source of the MTP process wastewater is not particularly limited, and wastewater with organic matter produced by reaction processes such as fixed bed, fluidized bed, and moving bed can be used.

[0015] In some embodiments of the present invention, the MTP process wastewater is not...

Embodiment approach

[0037] According to a preferred embodiment of the present invention, the apparent viscosity of the coal-water slurry is 1000-1400mPa·s, the concentration of the coal-water slurry is 57-65wt%, and the average particle size of the coal-water slurry is 70 -85 μm.

[0038] The third aspect of the present invention provides a synthesis gas preparation method, the method comprising: mixing the aforementioned coal-water slurry of the present invention with oxygen for gasification reaction to obtain synthesis gas.

[0039] In some embodiments of the present invention, preferably, the volume ratio of the coal-water slurry to oxygen is 1:300-450.

[0040] In some embodiments of the present invention, preferably, the conditions of the gasification reaction include: a temperature of 1000-1500° C. and a pressure of 2-5 MPa.

[0041] In the present invention, the device for performing the gasification reaction is not particularly limited, and may be a conventional device in the field, such...

Embodiment 1

[0058] 700g MTP process waste water 1 is heated to 50 ℃, adopts sodium hydroxide solution to adjust the pH value of the heated MTP process waste water 1 to 8.5, then with 300g chemical additives (comprising 50wt% sodium lignosulfonate, 20wt% sulfonic acid Sodium humate and 30wt% sodium polystyrene sulfonate) and 1500g water were mixed and stirred to obtain a slurry; 6000g coal 1 and 1500g waste MTP catalyst 1 were crushed by a crusher to obtain coal with an average particle size of 75 μm 1 and spent MTP catalyst 1 with an average particle size of 50 μm;

[0059] Then, the slurry is mixed with the crushed coal 1 and the spent MTP catalyst 1, and the mixed slurry is ground by a high-speed grinder at a speed of 200 rpm to obtain a coal water slurry.

[0060] The resulting coal water slurry was placed for 24 hours to observe the state: no delamination, no obvious precipitation. The performance parameters of the coal water slurry are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com