Oil-containing sludge coal slurry and preparation method thereof

A technology for oily sludge and sludge, applied in the field of oily sludge coal slurry and its preparation, can solve the problems of low carbon conversion rate, strict requirements for dispersants, low slurry concentration, etc., and achieves high carbon conversion rate and fluidity. Good, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Raw materials

[0020] Meaning of symbols: moisture (M), ash (A), volatile matter (V) and fixed carbon (FC). Calorific value (Q d ). Meanings of subscript symbols: received basis (ar): the state of the sample is the state in which the batch of samples was received; dry basis (d): the state in which the sample is in the state of no moisture.

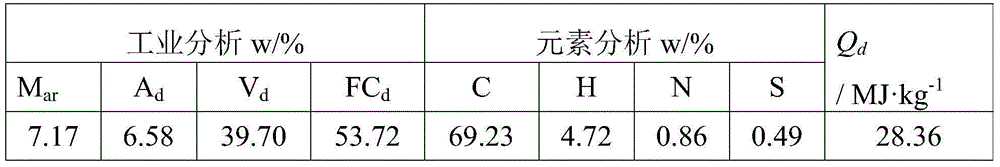

[0021] (1) The coal used in this embodiment is Shenfu coal, and the specific components are shown in the table below.

[0022]

[0023] (2) Dispersant: sodium naphthalenesulfonate

[0024] (3) Oily sludge: It was taken from Shanghai Gaoqiao Petrochemical Sewage Treatment Plant. The specific components of the original sample and the dried sample are shown in the table below.

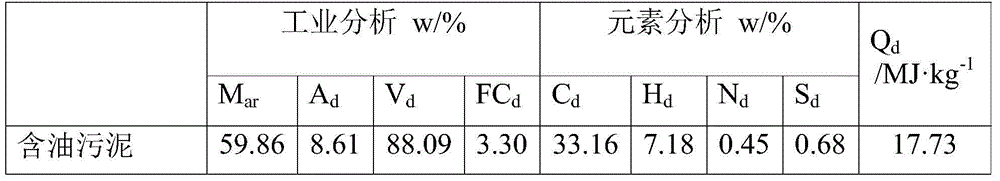

[0025]

[0026] (4) water

[0027] 2. Preparation conditions

[0028] (1) Raw material ratio, weight fraction.

[0029] coal

57wt%

oily sludge

14.3wt%

water

28wt%

Dispersant

0.7wt%

[0030...

Embodiment 2

[0039] 1. Raw materials

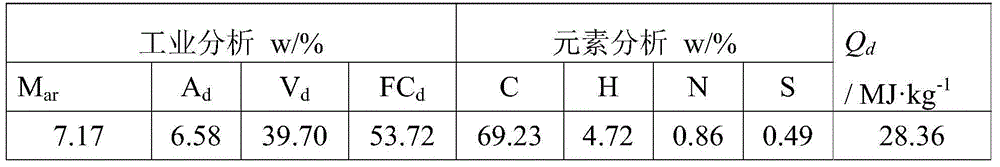

[0040] (1) The coal used in this embodiment is Shenfu coal, and the specific components are shown in the table below. Meaning of symbols: moisture (M), ash (A), volatile matter (V) and fixed carbon (FC). Calorific value (Q d ). Meanings of subscript symbols: received basis (ar): the state of the sample is the state in which the batch of samples was received; dry basis (d): the state in which the sample is in the state of no moisture.

[0041]

[0042] (2) Dispersant: sodium lignosulfonate

[0043] (3) Oily sludge: It was taken from Shanghai Gaoqiao Petrochemical Sewage Treatment Plant. The specific components of the original sample and the dried sample are shown in the table below.

[0044]

[0045] (4) water

[0046] 2. Preparation conditions

[0047] (1) Raw material ratio, weight fraction.

[0048] coal

62wt%

oily sludge

3wt%

water

34.8wt%

Dispersant

0.2wt%

[0049] (2) Preparatio...

Embodiment 3

[0058]This example is basically the same as Example 1, the difference is that the dispersant uses sodium methylnaphthalenesulfonate formaldehyde condensate, the final product has good flow, high slurry concentration, good stability, and replaces coal water slurry for patent application number The synthesis gas is prepared for the multi-nozzle opposed coal-water slurry gasifier described in 98110616.1. The effective gas components (carbon monoxide and hydrogen) can reach more than 80%, and the carbon conversion rate is more than 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com