Biological oil-coal slurry and method for preparing gas from same

A technology of bio-oil and coal slurry, which is applied in the manufacture of combustible gas, petroleum industry, granular/powdered fuel gasification, etc., can solve the problems of limited service life of refractory material layer, high equipment investment and low application range, and achieve equipment saving The effect of investment and operating costs, broad prospects for industrial application, and strong adaptability to coal types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Raw materials:

[0031] (1) Datong coal powder, with an average particle size of 10 microns;

[0032] (2) Pyrolysis liquid obtained by pyrolysis of sawdust;

Embodiment approach

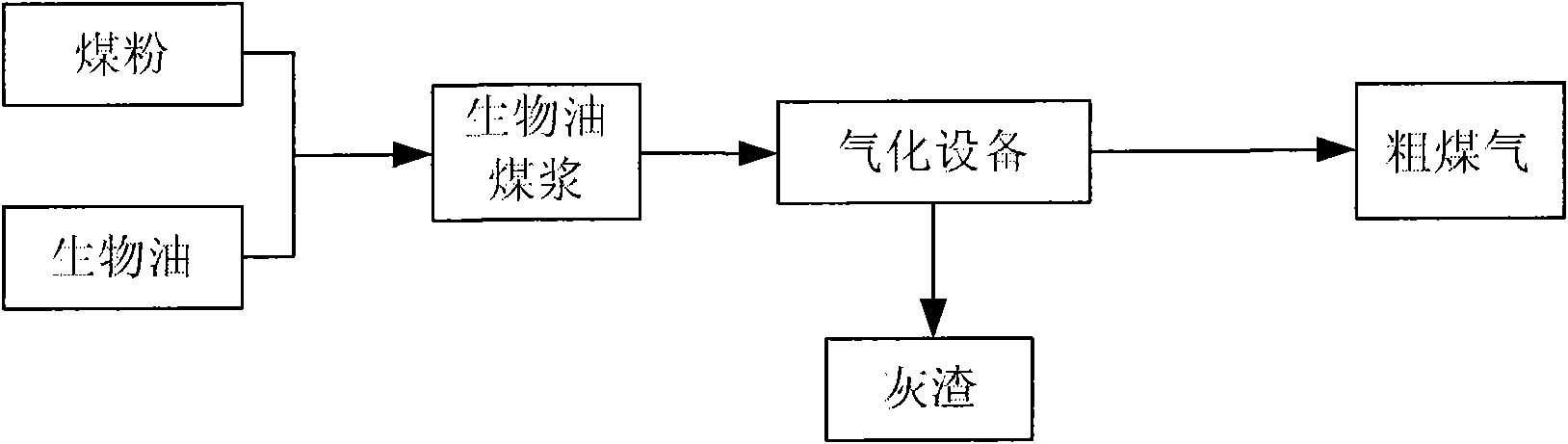

[0034] 1) After mixing 80 parts by weight of mixed coal powder and 20 parts by weight of pyrolysis liquid, a bio-oil-coal slurry is prepared by stirring. The prepared bio-oil-coal slurry is used as a combustion fuel or gasification raw material.

[0035] 2) Take the prepared bio-oil-coal slurry and use a delivery pump to drive it into a gasifier lined with a water wall through a delivery pipe and nozzles. The atomized bio-coal-oil slurry and air are generated in the gasifier. Pyrolysis, gasification and combustion reactions, the reacted ash is discharged in liquid form through the liquid slag discharge port, and the gas product is crude gas.

Embodiment 2

[0037] Raw materials:

[0038] (1) Mixed coal powder with an average particle size of 500 microns;

[0039] (2) Pyrolysis liquid obtained from pyrolysis of straw;

[0040] method of execution

[0041] 1) 20 parts by weight of mixed coal powder and 80 parts by weight of pyrolysis liquid are mixed and stirred to prepare a bio-oil-coal slurry. The prepared bio-oil-coal slurry is used as a combustion fuel or gasification raw material.

[0042] 2) Take the prepared bio-oil-coal slurry and use a transfer pump to drive it into a gasifier lined with a water-cooled wall through a delivery pipe and nozzles. The atomized bio-coal-oil slurry and air heat up in the gasifier. Decomposition, gasification and combustion reactions, the ash after the reaction is discharged in liquid form through the liquid slag discharge port, and the gas product is the crude synthesis gas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com