Small-sized cyclone-melting pulverized coal furnace

A pulverized coal furnace and cyclone technology, which is applied in the combustion type, the use of multiple fuel combustion, the use of lump fuel and powder fuel combustion, etc., can solve the problem of high coal quality requirements, high carbon content in fly ash, and unstable combustion. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

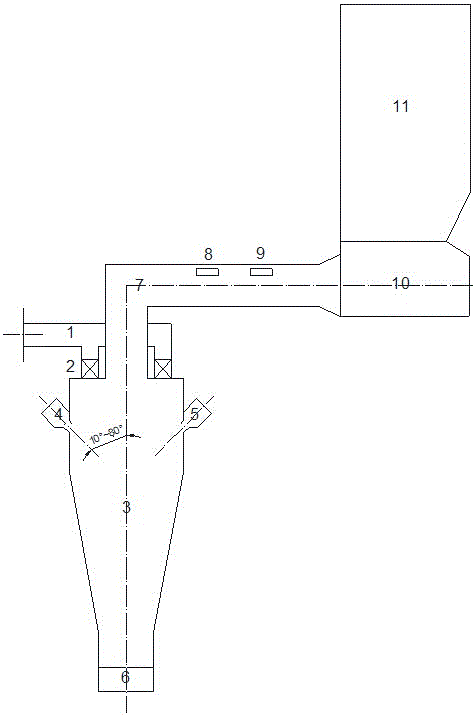

[0013] refer to figure 1 , The small cyclone melting pulverized coal furnace is mainly composed of a blade-type swirling burner 1, a cyclone melting combustion chamber 3, a high-temperature flue gas outlet pipe 7, a burnout chamber 10, and a heat exchange furnace 11. The vane type swirl burner 1 is connected to the top of the melting combustion chamber 3, and the middle position of the top of the combustion chamber 3 is connected to the high-temperature flue gas outlet pipe 7. 3 After the top is led out, it enters the burnout chamber 10 through a horizontal section, and finally enters the heat exchange furnace 11. When the device is running, the primary air carries pulverized coal through the blade-type swirl burner 1 into the melting combustion chamber 3, and at the same time, high-temperature air (secondary air) enters from the two tangential high-temperature flue gas inlets 4 and 5 arranged at the upper end of the combustion chamber , to ignite coal powder to form high-tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com