Embedded deep cooler for boiler flue gas

A boiler flue gas, deep cooling technology, applied in feed water heaters, preheating, steam generation, etc., can solve problems such as high exhaust gas temperature and increased water consumption of desulfurization towers, achieve high heat transfer efficiency, improve uniformity, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

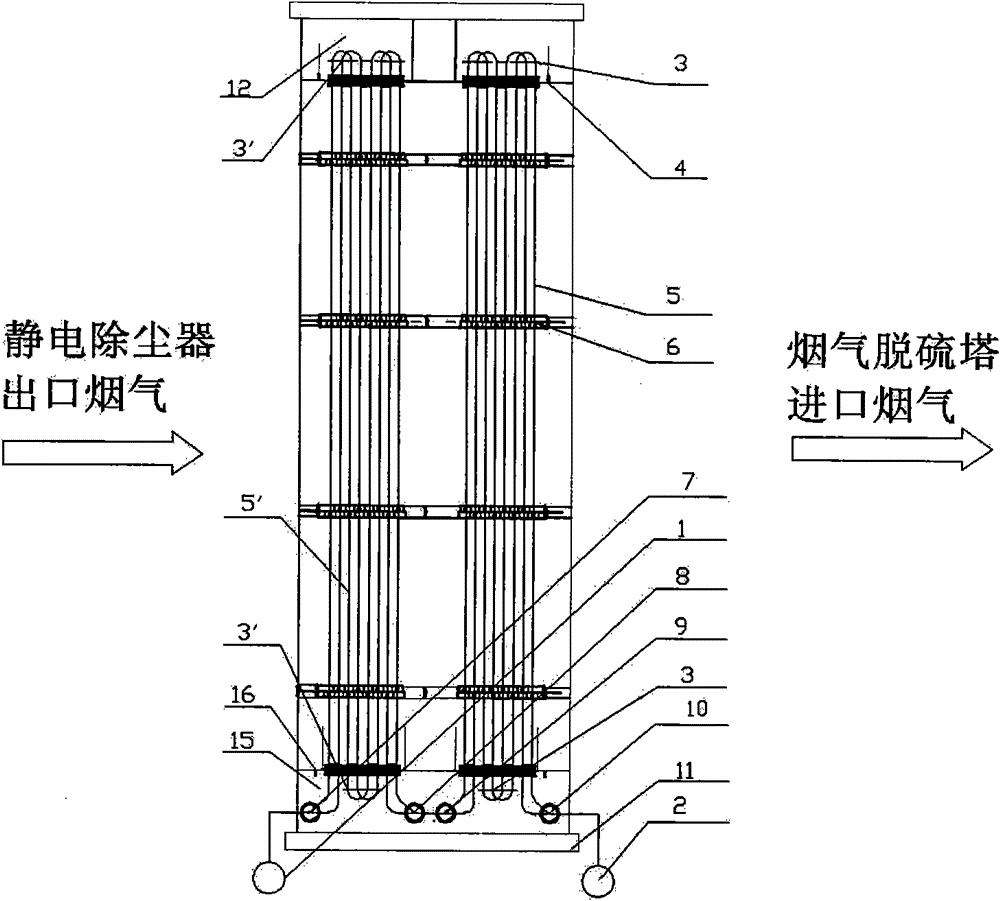

[0024] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

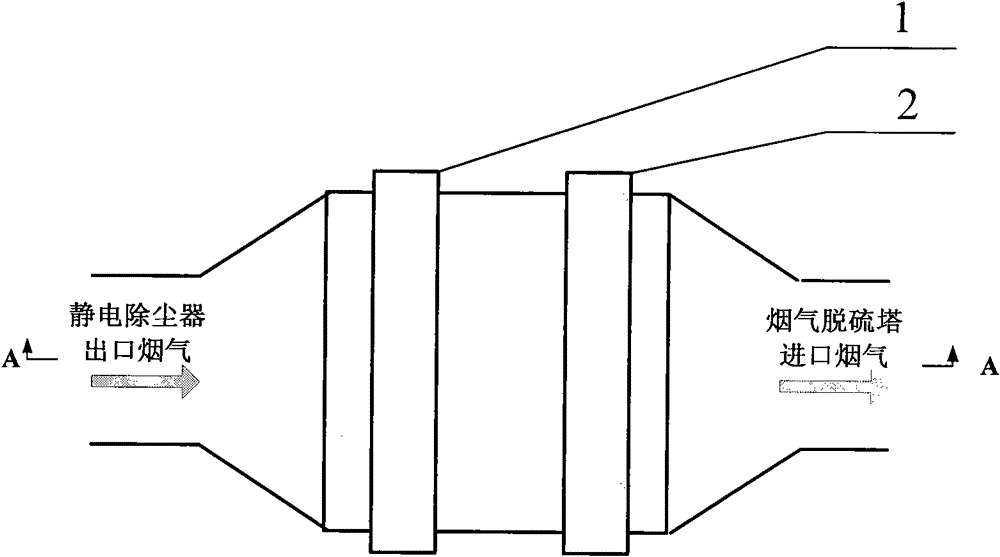

[0025] like figure 1 , figure 2 As shown, the present invention is arranged between the electrostatic precipitator and the flue gas desulfurization tower. The tower inlet flue is through-connected.

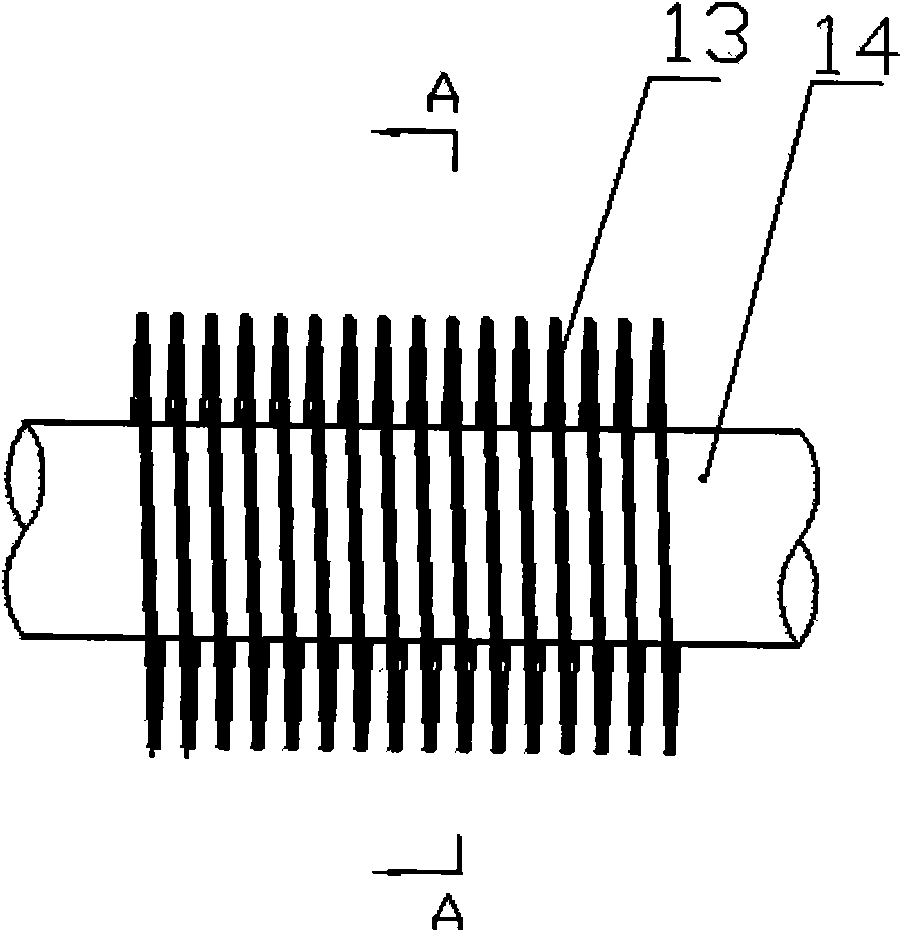

[0026] The present invention comprises a housing 11, the side of the housing 11 close to the inlet flue is a high-temperature section, and the side close to the outlet flue is a low-temperature section, and the flue gas partitions 4 and 16 divide the inner cavity of the housing 11 into an upper flue compartment 12 1. The flue in the middle and the flue compartment 15 in the lower part, the support plate 6 for supporting the first and second finned tube bundles 5, 5' is arranged in the flue; the high temperature section includes the inlet header 8 of the high temperature section, and the inlet The header 8 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com