Leather waste vaporizing combustion and heat recovery system, and operation method thereof

A leather waste and heat recovery technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of pollution, unfavorable cleaning and recycling of leather waste, waste water, waste gas secondary pollution, etc., to reduce NOX pollution and realize Effect of harmless treatment and reduction of fly ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

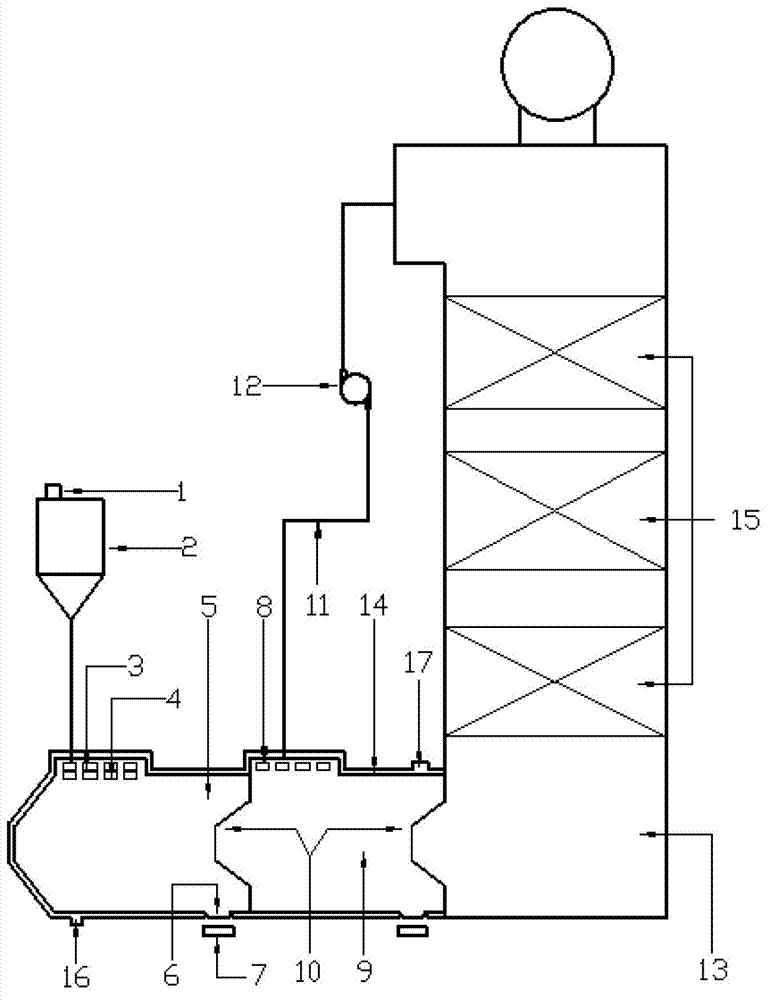

[0038] see figure 1 As shown, a leather waste gasification combustion and heat recovery system proposed by the present invention includes a feeding system, a gasification chamber 5, a combustion chamber 9, a slag discharge device and a waste heat recovery device. The gasification chamber 5 and the combustion chamber 9 are cylindrical, and the top tangential direction is respectively provided with a gasification chamber secondary air inlet 3 and a combustion chamber secondary air inlet 8; the top of the gasification chamber 5 is also provided with a gasification chamber The primary air inlet 4; the bottom of the gasification chamber 5 and the combustion chamber 9 is equipped with a slagging device, the outer wall of the gasification chamber 5 and the combustion chamber 9 is wrapped with an air preheating device 14, and the gasification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com