Boiler system utilizing garbage incineration synthesis gas

A technology for synthesis gas and gasifier, which is applied to incinerators, steam boilers, combustion methods, etc., to achieve the effects of improving energy conversion efficiency, heat exchange efficiency, and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

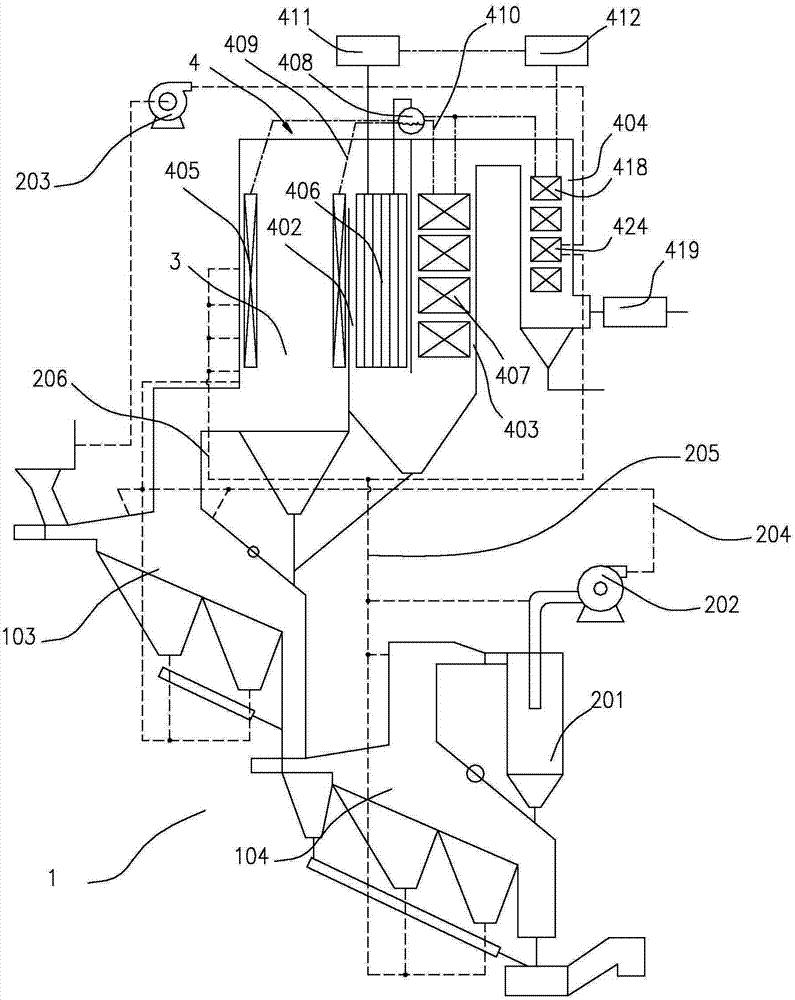

[0040] see Figure 1 to Figure 7 , which is a preferred embodiment of a boiler system utilizing refuse gasification to incinerate syngas.

[0041] In this embodiment, the boiler system includes a gasification furnace 103, an ember furnace 104, a boiler body 4 and its circulating air supply system. The gasification furnace 103 and the ember furnace 104 can be sealed or communicated. The hearth of the gasification furnace 103 Two independent primary air chambers 107 are respectively provided under the ember furnace 104 hearth, the front arch and the rear arch of the gasification furnace 103 are respectively provided with secondary air supply ports 115, and the gasification furnace 103 The vault of the ember furnace 104 is provided with a first flue gas outlet 112 , and the vault of the ember furnace 104 is provided with a second flue gas outlet 113 .

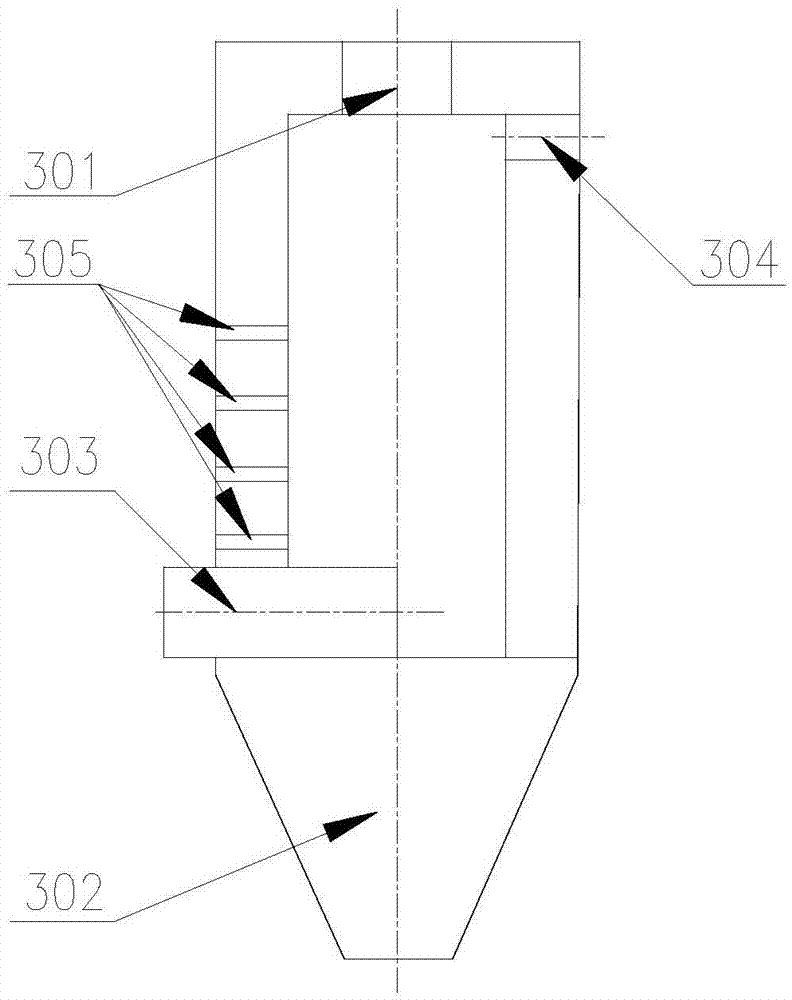

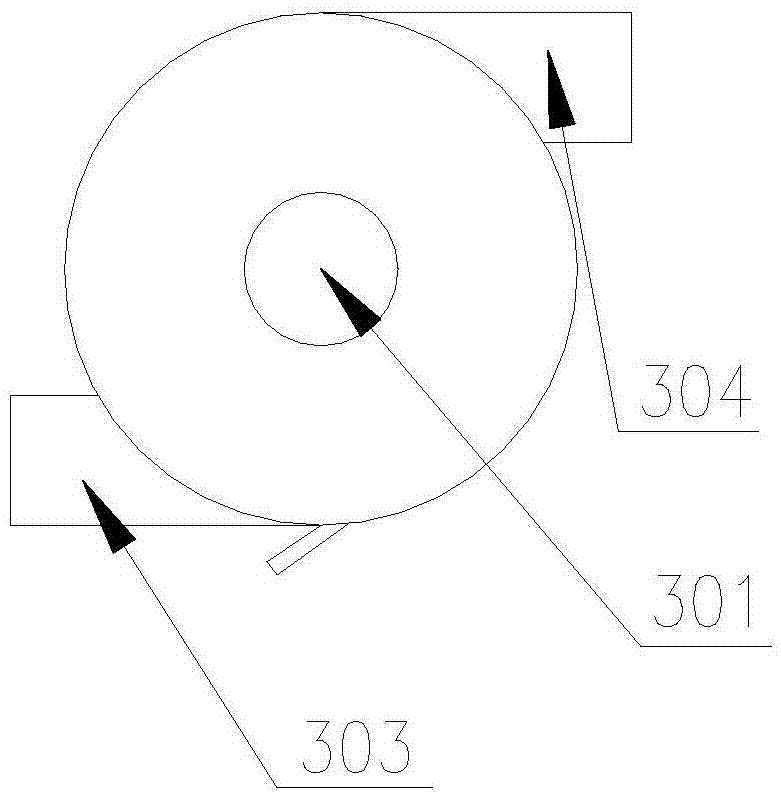

[0042] The boiler body 4 has a cyclone combustion chamber 3, a furnace chamber a402, a furnace chamber b403, and a furnace cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com