Cermet composite material and coating preparation method thereof

A metal-based composite and coating technology, which is applied in the preparation of metal-based composite powder and its coating, and the preparation of composite powder and its composite coating, can solve the problems that do not involve iron-based-ceramic composite thermal insulation coating , to achieve the effect of low cost, low thermal conductivity and wide range of powder particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

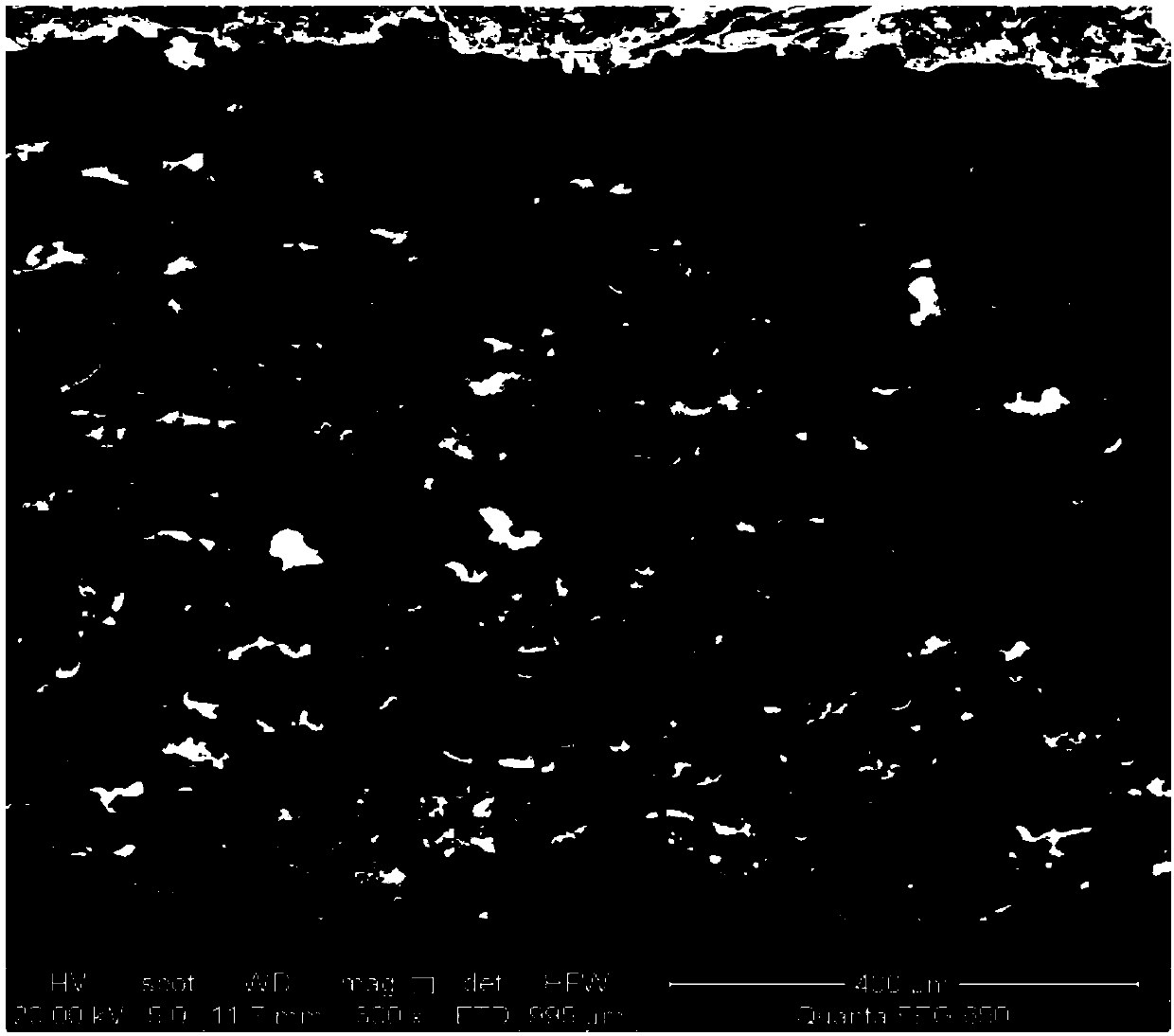

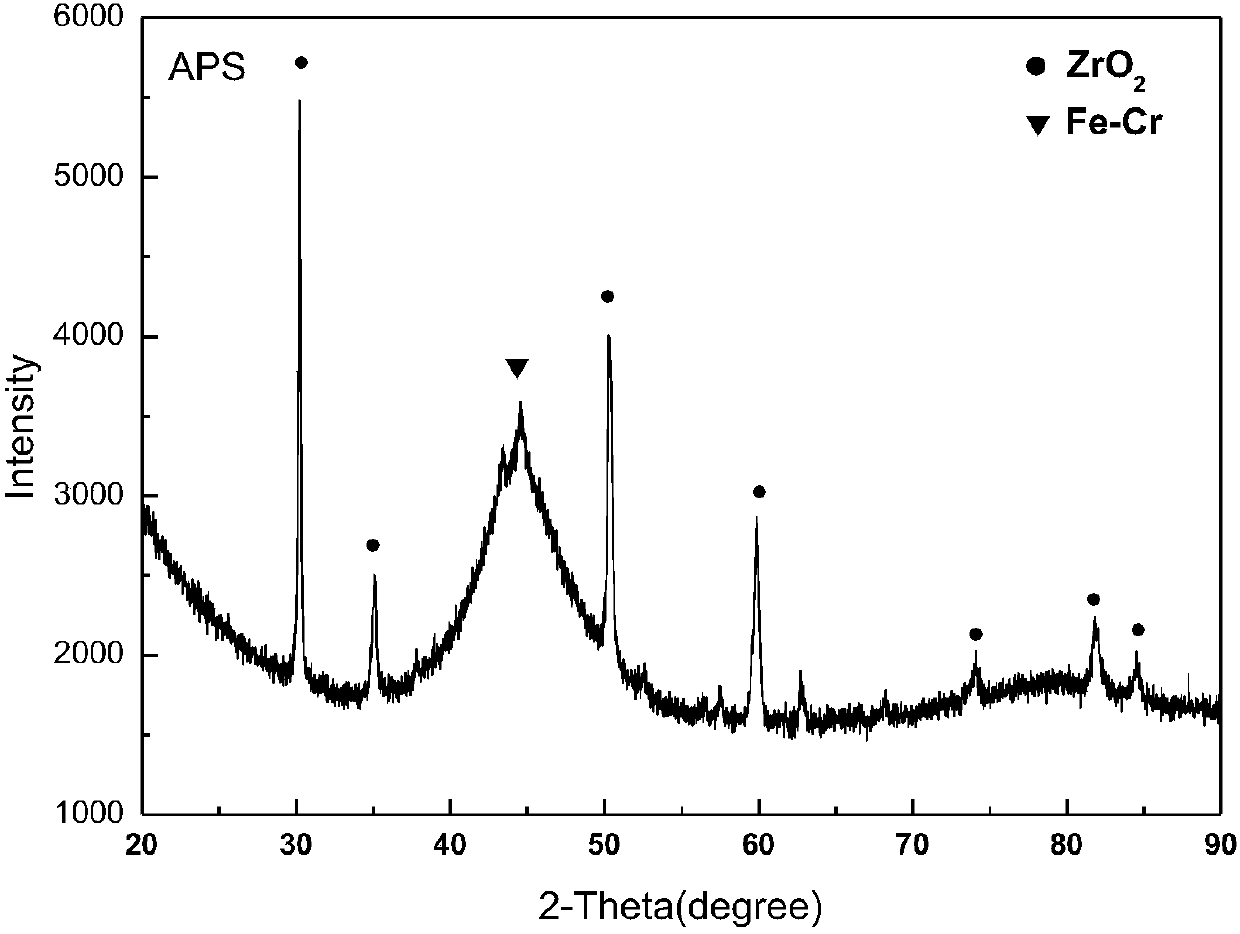

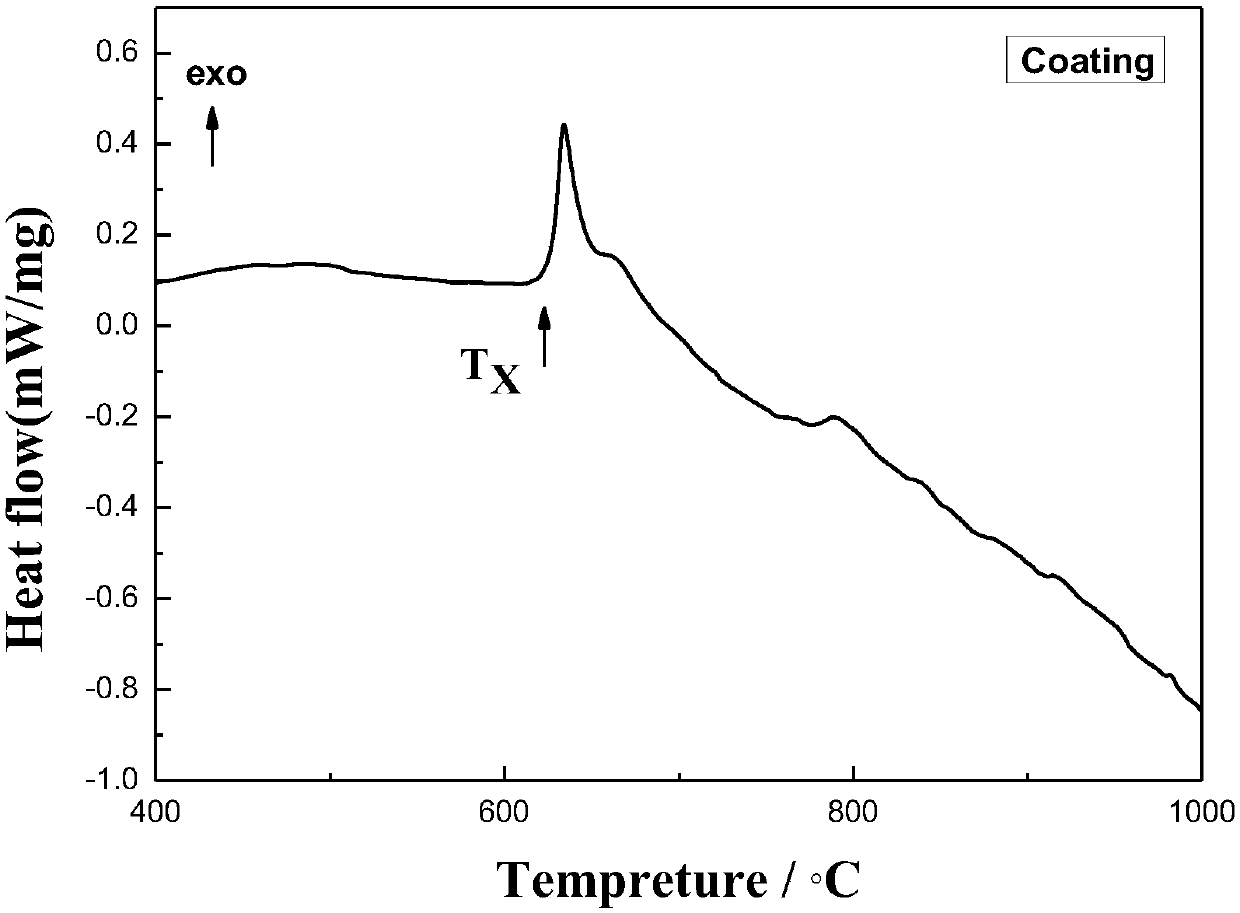

[0033] The mass percentages of raw materials in the iron-based-ceramic composite powder are as follows: Fe-based alloy powder raw materials: ferroboron (B: 18%): 24%, ferroniobium (Nb: 65%): 13%, ferrosilicon (Si: 75%) ): 3%, pure chromium: 17% and pure iron 43%; mixed with YSZ (YSZ accounts for 6% of the total mass). Preparation of iron-based-ceramic composite coating, spraying process parameters: current: 600A, argon flow: 35L / min, hydrogen flow: 10L / min, powder feeding rate: 54g / min, spraying distance: 130mm.

Embodiment 2

[0035] The mass percentages of raw materials in the iron-based-ceramic composite powder are as follows: Fe-based alloy powder raw materials: ferroboron (B: 18%): 24%, ferroniobium (Nb: 65%): 13%, ferrosilicon (Si: 75%) ): 3%, pure chromium: 17% and pure iron 43%; mixed with YSZ (YSZ accounts for 12% of the total mass). Preparation of iron-based-ceramic composite coating, spraying process parameters: current: 600A, argon flow: 35L / min, hydrogen flow: 10L / min, powder feeding rate: 54g / min, spraying distance: 130mm.

Embodiment 3

[0037]The mass percentages of raw materials in the iron-based-ceramic composite powder are as follows: Fe-based alloy powder raw materials: ferroboron (B: 18%): 24%, ferroniobium (Nb: 65%): 13%, ferrosilicon (Si: 75%) ): 3%, pure chromium: 17% and pure iron 43%; mixed with YSZ (YSZ accounts for 18% of the total mass). Preparation of iron-based-ceramic composite coating, spraying process parameters: current: 600A, argon flow: 35L / min, hydrogen flow: 10L / min, powder feeding rate: 54g / min, spraying distance: 130mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com