Amorphous powdered alloy and method for producing the same

An amorphous alloy and powder technology, which is applied in the field of preparation of amorphous alloy powder, can solve the problems of inability to prepare a particle size range, limit the formability of amorphous alloys, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the amorphous alloy powder of the present invention comprises: (a), under protective atmosphere or vacuum condition, smelting Zr-based, Cu-based, Ti-based, Ni-based or Re-based amorphous alloy raw materials; ( b) Spraying the molten metal into a mist in a protective atmosphere, and rapidly cooling and solidifying to form an amorphous alloy powder; wherein, in step (a), rare earth elements are added together with the amorphous alloy raw material for smelting.

[0020] The alloy raw material used in the present invention is not particularly limited, and can be known to those skilled in the art. For example, the Zr-based amorphous alloy Zr in the present invention aCu b Ni c m d N e The raw materials are: Zr with a mole percentage of 40≤a≤70; Cu with 2≤b≤20; Ni with 2≤c≤20, M with 2≤d≤30 and N with 0.1≤e≤10, and a +b+c+d+e=100%; N is rare earth element La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Y, Nb, Hf One or more mixtures; M ...

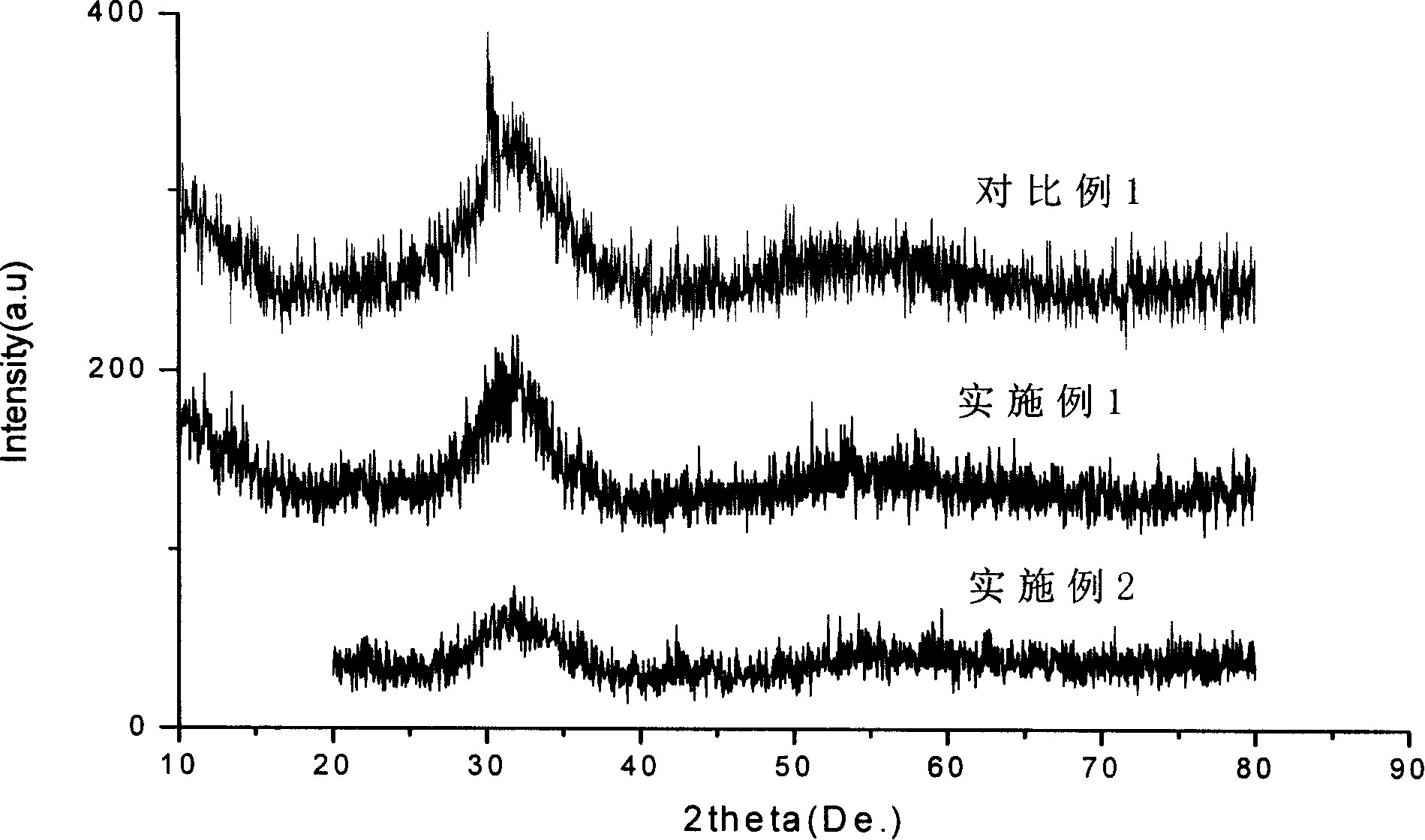

Embodiment 1

[0028] This embodiment is used to illustrate a kind of Zr that the present invention provides 55 Cu 20 Ni 12 al 11 Y 2 The preparation method of amorphous alloy powder.

[0029] Prepare amorphous alloy raw materials according to mole percentage: 55% Zr, 20% Cu, 12% Ni, 11% Al and 2% Y. The purity of the rare earth element Y is not lower than 98wt%, and the purity of other non-impurity elements in the alloy components is not lower than 98wt%.

[0030] Put the raw materials and rare earth elements into the vacuum induction metal atomization powder making furnace, vacuumize the induction furnace and fill it with 10 -2 Atm argon, use induction melting to heat at about 1000°C for 3 to 5 minutes, and the raw materials are melted and mixed evenly.

[0031] The molten metal is subjected to high-pressure inert gas argon, and the gas pressure is 500Mpa, so that the metal liquid is sprayed into a mist, and rapidly cooled to form Zr with a particle size of 100 microns. 55 Cu 20 Ni...

Embodiment 2

[0033] This embodiment is used to illustrate a kind of Ni provided by the present invention 55 Zr 20 Ti 12 Si 5 Nb 8 The preparation method of amorphous alloy powder.

[0034] The raw material of amorphous alloy is prepared according to mole percentage: 55% Ni, 20% Zr, 12% Ti, 5% Si and 8% Nb. The purity of the rare earth element Nb is not lower than 99wt%, and the purity of other non-impurity elements in the alloy is not lower than 98.5wt%.

[0035] Put the raw materials and rare earth elements into the vacuum induction metal atomization powder making furnace, vacuumize the induction furnace and fill it with 10 -2 Atm argon, use induction melting to heat at about 1000°C for 3 to 5 minutes, and the raw materials are melted and mixed evenly.

[0036] The molten metal is subjected to high-pressure inert gas argon, and the gas pressure is 100Mpa to make the metal liquid spray into a mist, and it is rapidly cooled to form Ni with a particle size of 1800 microns. 55 Zr 20 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com