Preparation method for spherical aluminum oxide powder

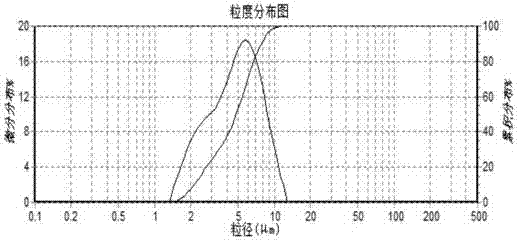

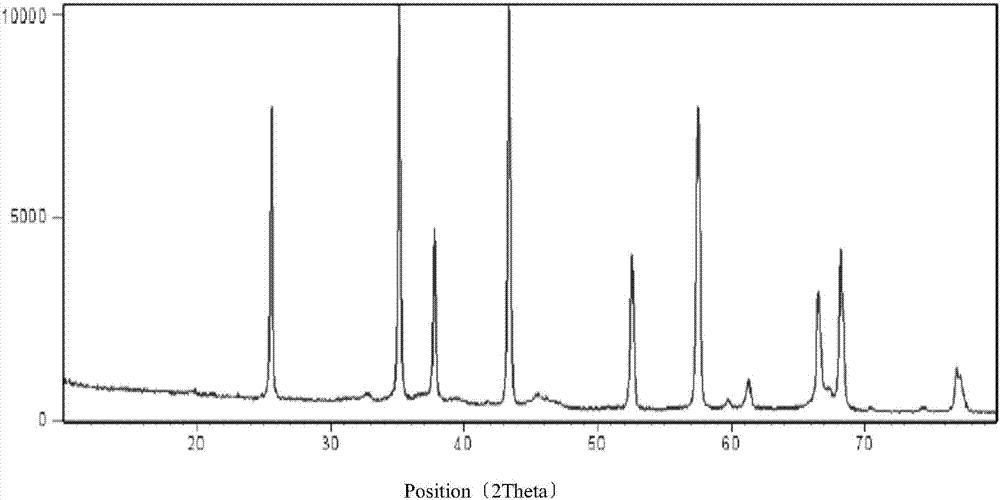

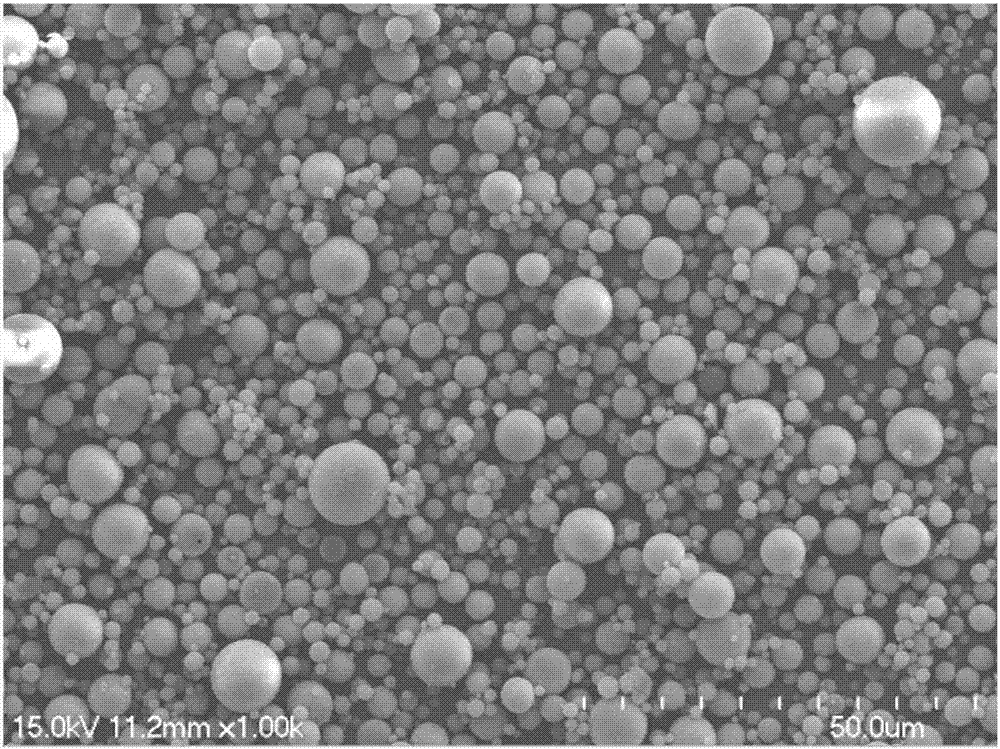

A spherical alumina and alumina powder technology, applied in the field of chemistry, can solve the problems of easy agglomeration or fusion between particles, complex equipment engineering, low spheroidization rate, etc., and achieve high α-phase alumina content and smooth particle surface. , the effect of high filling density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0047] Dissolve 20g of pseudoboehmite powder into 100g of pure water with an appropriate amount of nitric acid, stir well to turn the mixture into a light blue transparent PH=3.9 aluminum sol, then mix the aluminum sol with 20g of alumina powder and 10g of lactic acid Disperse, prepare a uniform suspension slurry, mix and disperse the prepared mixed slurry with 300g cyclohexane, 6g alkylphenol polyoxyethylene ether, and emulsify with a homogeneous emulsifier for 10 minutes, and the emulsified emulsion is in a stirring state Slowly add 30g of tetramethylammonium hydroxide with a concentration of 15%. After the solidification of the aluminum sol gel in the emulsion, the emulsion was aged at room temperature for 2 hours, and then the spherical solid particles in the emulsion were solidified by a centrifuge. Liquid separation, the separated cyclohexane is recycled, the spherical solid particles are dried in an oven at 120°C for 6 hours, and the dried powder is calcined in a high-te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spheroidization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com