Non-steam autoclaved PHC tubular pile concrete

A PHC pipe pile and concrete technology, applied in the field of concrete materials, to achieve the effects of reducing production costs, good work performance, and reducing environmental pollution

Active Publication Date: 2019-10-25

浙江沪嘉住宅工业股份有限公司

View PDF4 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The concrete is used to prepare PHC pipe columns, which can meet the mold release strength of non-pressure steamed PHC pipe piles and the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

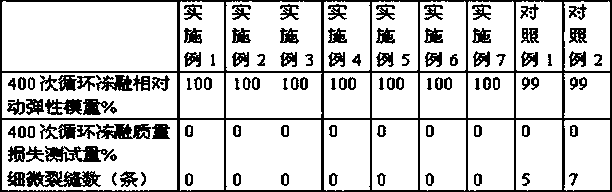

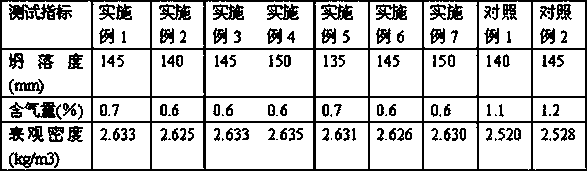

The invention relates to non-steam autoclaved PHC tubular pile concrete, and belongs to the technical field of concrete materials. The non-steam autoclaved PHC tubular pile concrete is composed of a gelling main material, gelling auxiliary materials, a fine aggregate, a coarse aggregate, an admixture, expansion agents, an adhesive, a water reducing agent and a water storage agent, in particular, triethanolamine, lithium sulfate, nitrite, phosphoric acid, copper monoxide powder, aluminum hydroxide are used as the gelling auxiliary materials, tartaric acid, sodium silicate, calcium sulphoaluminate, magnesium oxide, calcium oxide and anhydrite are used as the expansion agents, and hydroxypropyl methylcellulose is used as the water storage agent. PHC tubular piles produced by the concrete havethe good working performance under the normal-temperature non-steam autoclaved condition, the gas content of the concrete is greatly decreased, the contraction amplitude can be lowered, and cracks are avoided; the early strong progress is advanced, the later compressive strength is increased, and the speed is high; the durability and relative dynamic elasticity modulus are also greatly improved,the anti-freezing and anti-cracking properties are high, and any micro-crack is avoided after a large number of subcycles of freeze thawing; and the cost can further be lowered, and the environmentalpollution is reduced.

Description

technical field [0001] The invention relates to the technical field of concrete materials, in particular to pressure-free steamed PHC pipe pile concrete. Background technique [0002] Prestressed high-strength concrete pipe piles (hereinafter referred to as PHC pipe piles) adopt centrifugal forming technology, and the concrete strength grade is not lower than C80. In order to achieve the high strength level of concrete, high-strength cement, high-efficiency water reducer, and well-graded sand and gravel are usually used. Aggregates, including mineral powder, finely ground sand, etc. [0003] Atmospheric pressure steam curing or high pressure steam curing is used in the production process of PHC pipe piles. The purpose of atmospheric pressure steam curing process is to speed up the early hydration process of concrete and improve the turnover of formwork; The thermal synthesis reaction can increase and change the hydration products of the cementitious material, thereby impro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B28/04C04B40/02C04B111/20

CPCC04B28/04C04B40/024C04B2111/29C04B2201/05C04B2201/20C04B2201/52C04B22/165C04B14/309C04B14/303C04B24/122C04B22/085C04B22/147C04B14/02C04B14/06C04B14/048C04B18/08C04B18/141C04B18/146C04B24/06C04B12/04C04B22/142C04B22/066C04B22/064C04B22/143C04B2103/302C04B24/383

Inventor 袁启良张光力李故新石永军龚平张伦德

Owner 浙江沪嘉住宅工业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com