Air cleaning single region electronic dust-collecting unit

An air purification, single-zone technology, applied in the direction of electrode structure, electrostatic separation, etc., can solve the problems of air velocity limitation in dust collection area, application field limitation, deformation of electrode plate in dust collection area, etc. Simple, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

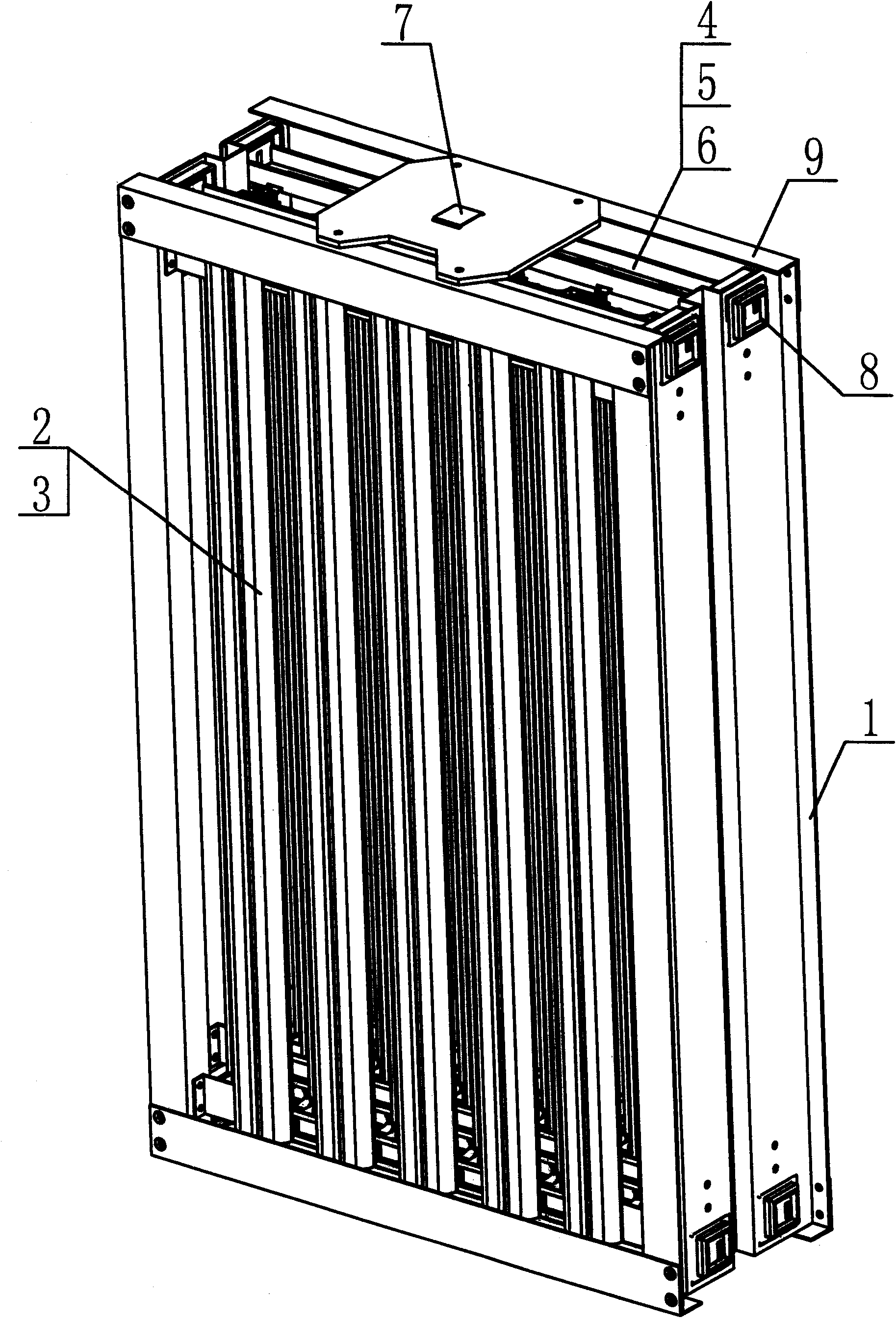

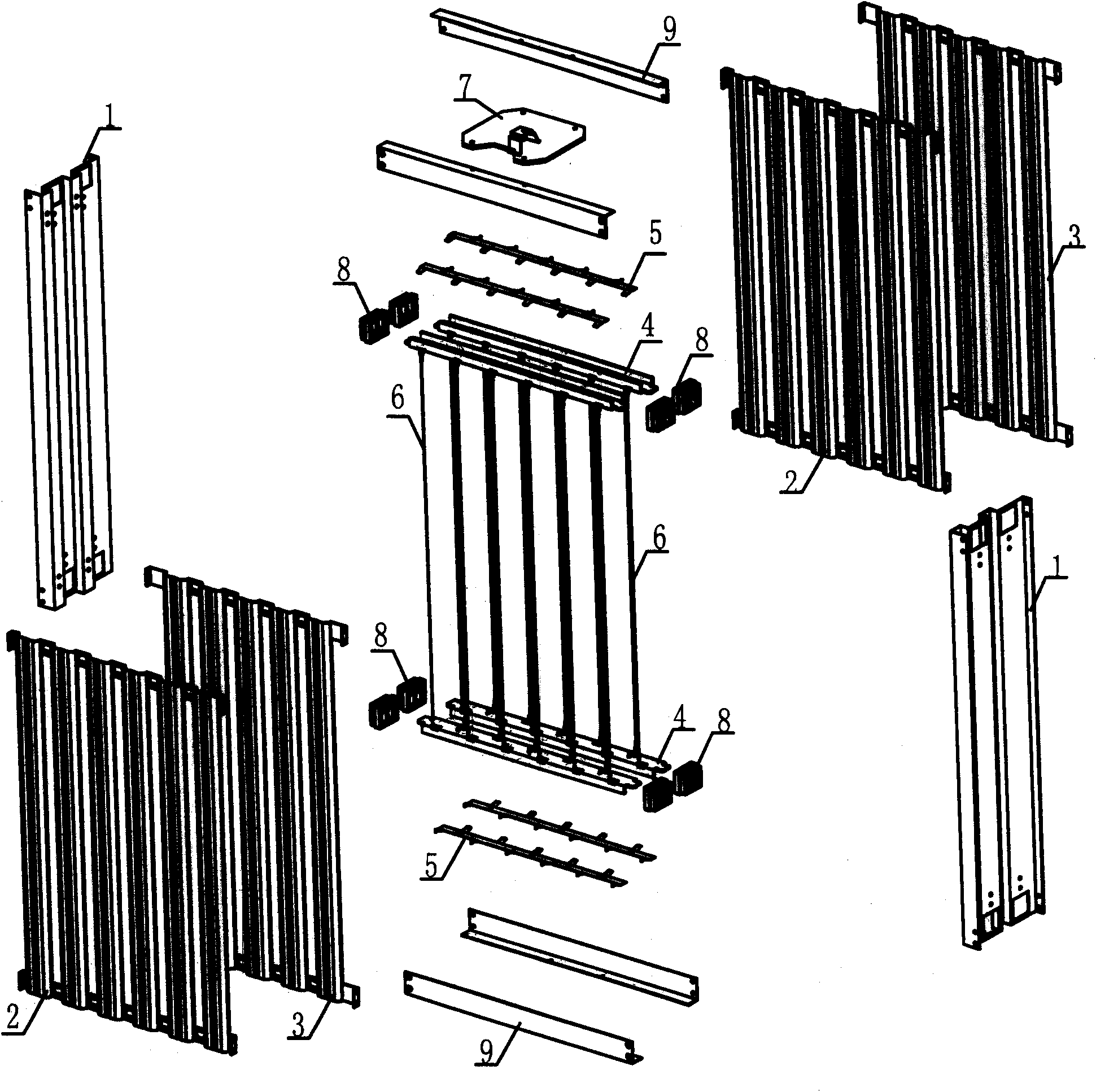

[0019] Example: from figure 1 with figure 2 It can be clearly seen that the single-zone electronic dust collection unit is composed of side plate 1, dust collection plate A 2, dust collection plate B 3, electrode beam 4, electrode spring hook 5, electric line 6, electrode contact plate 7, Insulating pad 8 and beam 9 are formed.

[0020] The assembly relationship is as follows:

[0021] ①Insert the electrode spring hook 5 on the electrode beam 4 first, and then insert two insulating pads 8 on both ends of the electrode beam 4.

[0022] ②Insert multiple electrode beams 4 prepared according to the above ① into the two side plates 1 through the relevant holes in the side plates 1 respectively.

[0023] ③Insert the dust collecting board A2 and the dust collecting board B3 into the specified positions between the two side boards 1, and fix them on the side board 1 with rivets.

[0024] ④ Use four beams 9 to rivet the two side plates 1 into one.

[0025] 5. The electric wire 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com