Method for improving underground coal mine negative pressure suction dust removal technology

A negative pressure suction and process technology, applied in the fields of dust prevention, mining equipment, earthwork drilling, etc., can solve the problems of many auxiliary equipment, small dust removal air volume, complex process, etc., achieve more auxiliary equipment, high dust removal efficiency, connection Simple way to effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

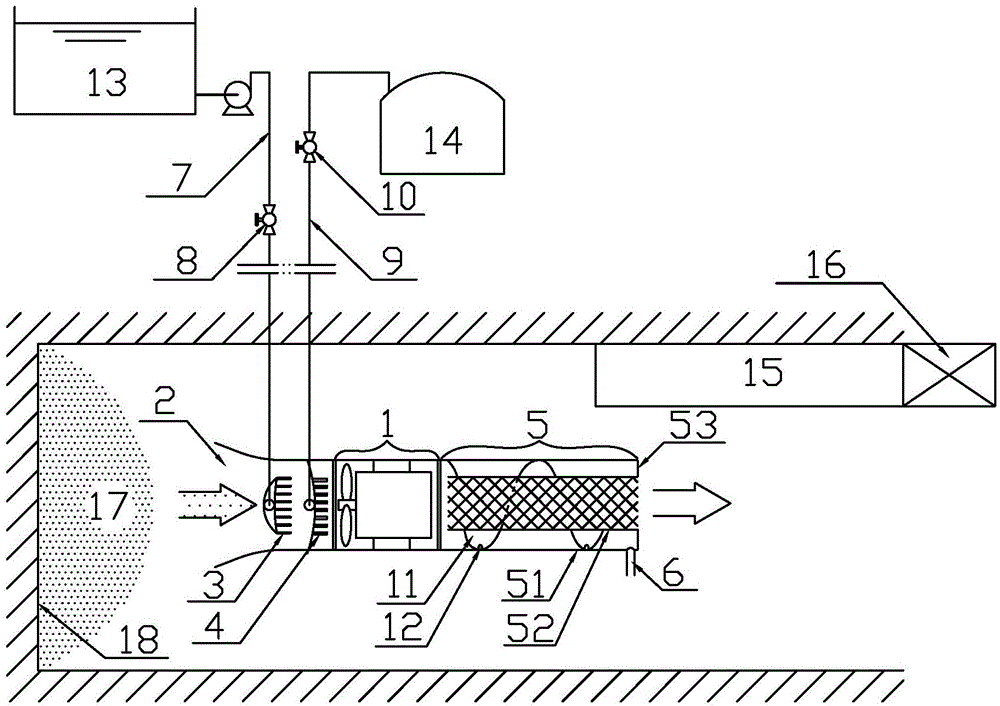

[0029] Example 1: as figure 1 As shown in the figure, the transformation method of the negative pressure suction and dust removal process in a coal mine includes the following steps:

[0030] 1).Equipment modification

[0031] 1) A bell mouth 2 is installed at the air inlet of the axial flow fan 1, and a plurality of evenly distributed high-pressure water jet pumps 3 and a plurality of evenly distributed high-pressure gas jet pumps 4 are added in the bell mouth 2, and the high-pressure gas jet pump 4 is located at a high pressure. Between the water jet pump 3 and the axial flow fan 1, a water film dust removal cylinder 5 is installed at the outlet of the axial flow fan 1. The water film dust removal cylinder 5 includes an outer cylinder 51 and an inner cylinder 52, wherein the inner cylinder 52 is formed by a cage. The frame and the flexible woven mesh wrapped on the cage frame are formed, the downstream end of the outer cylinder 51 is connected with an annular sealing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com