A dust removal device and dust removal method for pulverized coal pyrolysis/carbonization oil gas

A dust removal device, oil and gas technology, applied in gas dust removal and other directions, can solve the problems of poor separation effect of coke powder and oil and gas, unstable operation, low efficiency, etc., and achieve the effect of improving dust removal effect, reducing burden and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

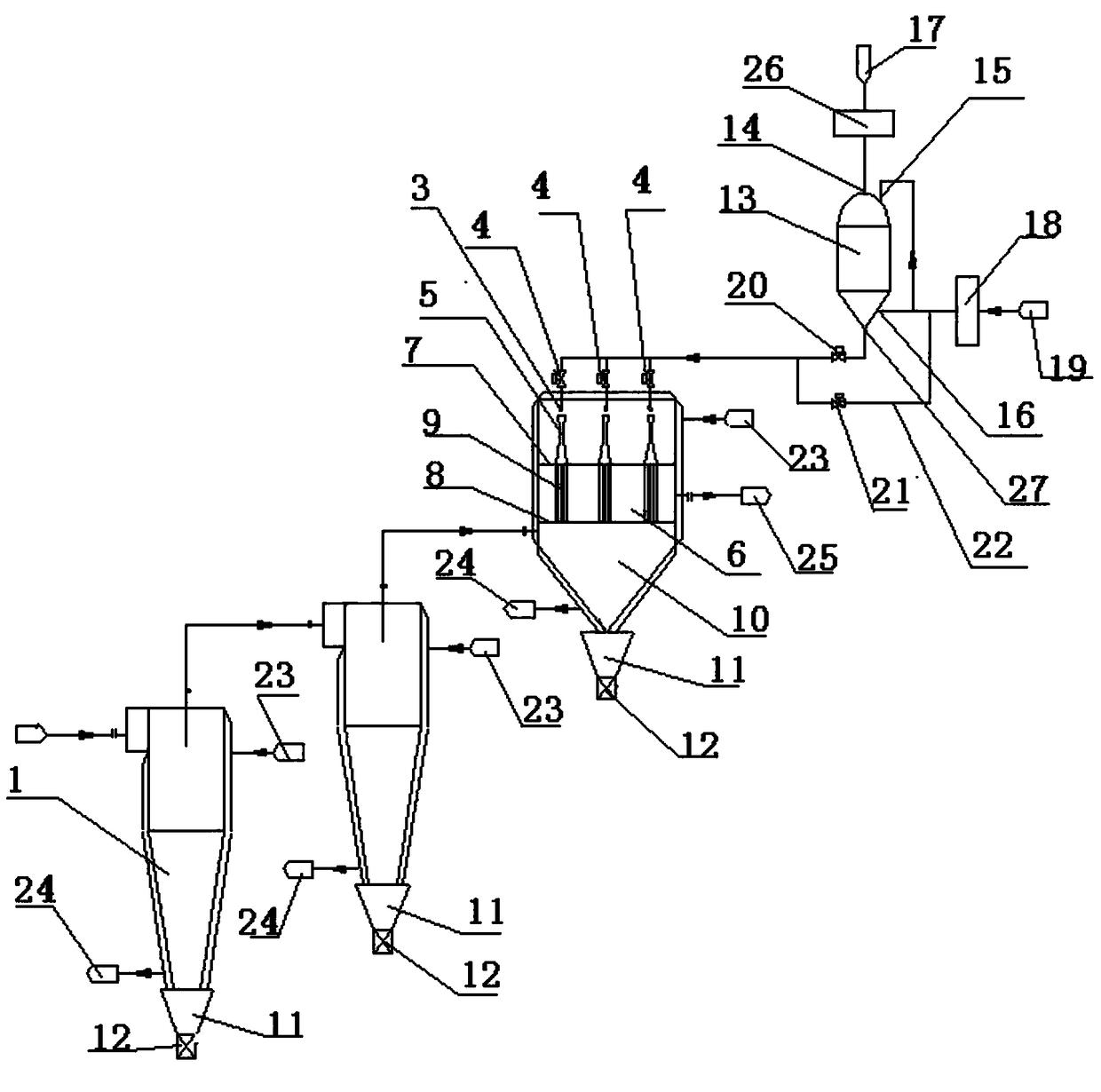

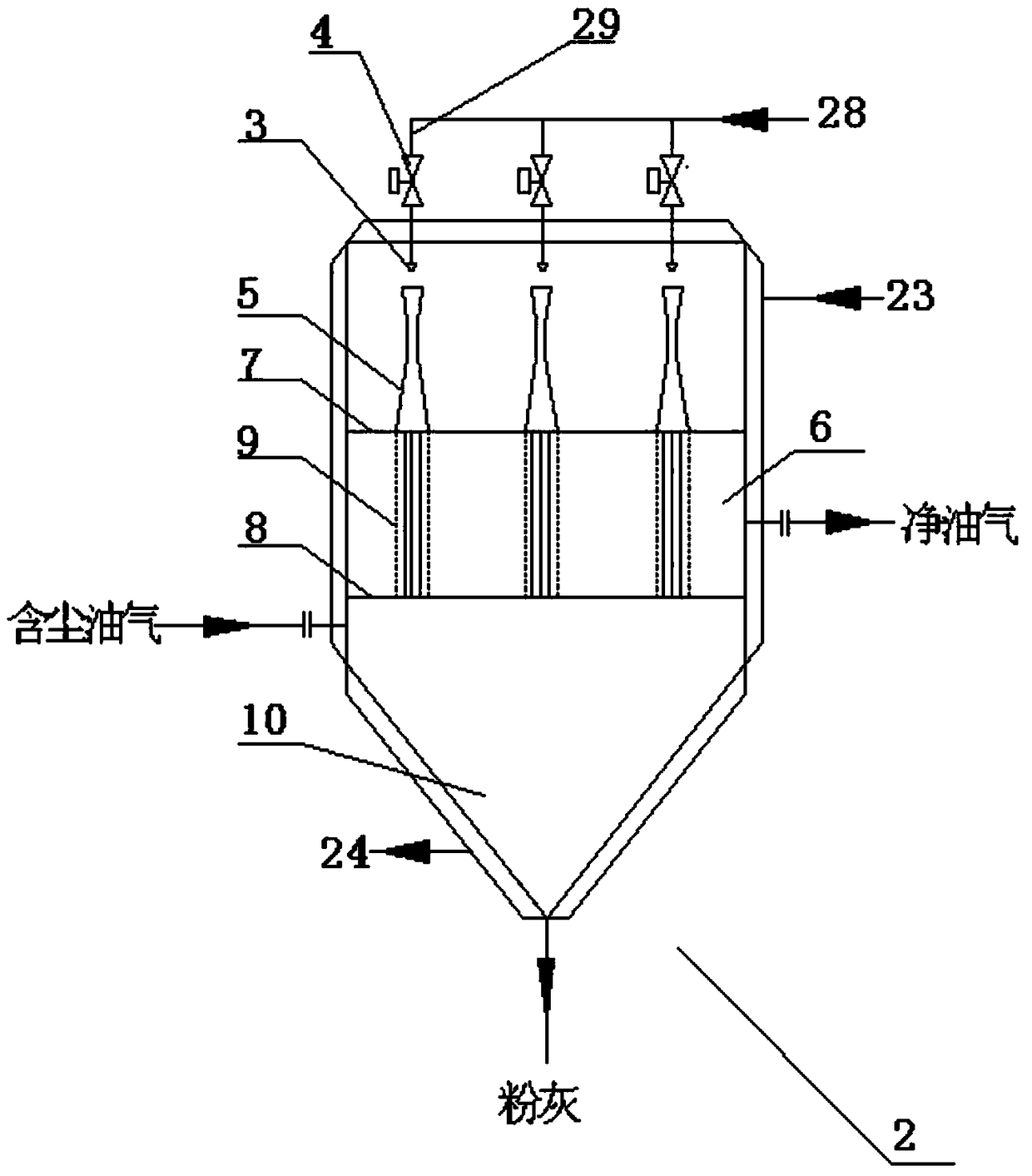

[0036] Such as Figure 1-2 The shown dust removal device for pulverized coal pyrolysis / carbonization oil and gas includes sequentially connected, dust removal pretreatment units, communicated with high-temperature oil and gas pipelines, and includes at least two stages of cyclone separators 1 in series for heat treatment of pulverized coal. Decomposition / carbonization of oil and gas for coarse dust removal; oil and gas filter 2, the oil and gas filter 2 is a closed tank, the interior is arranged in sequence from top to bottom, and the nozzle 3 is set on the top of the tank, and is imported through the high-temperature sand-containing gas The pipeline 29 communicates with the outside of the tank body. The high-temperature sand-containing gas inlet pipeline 29 is provided with a pulse control valve 4; the venturi tube 5 is vertically arranged below the nozzle 3; the clean oil and gas chamber 6 is perpendicular to the The Venturi tube 5 is set, and the inside is provided with a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com