Method and system for improving quality of low-rank coal

A low-rank coal and lignite technology, applied in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problems of single, fixed distribution, energy mismatch between units, etc., achieve flexible combination, save equipment investment, and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present application will be described in detail below with reference to the accompanying drawings.

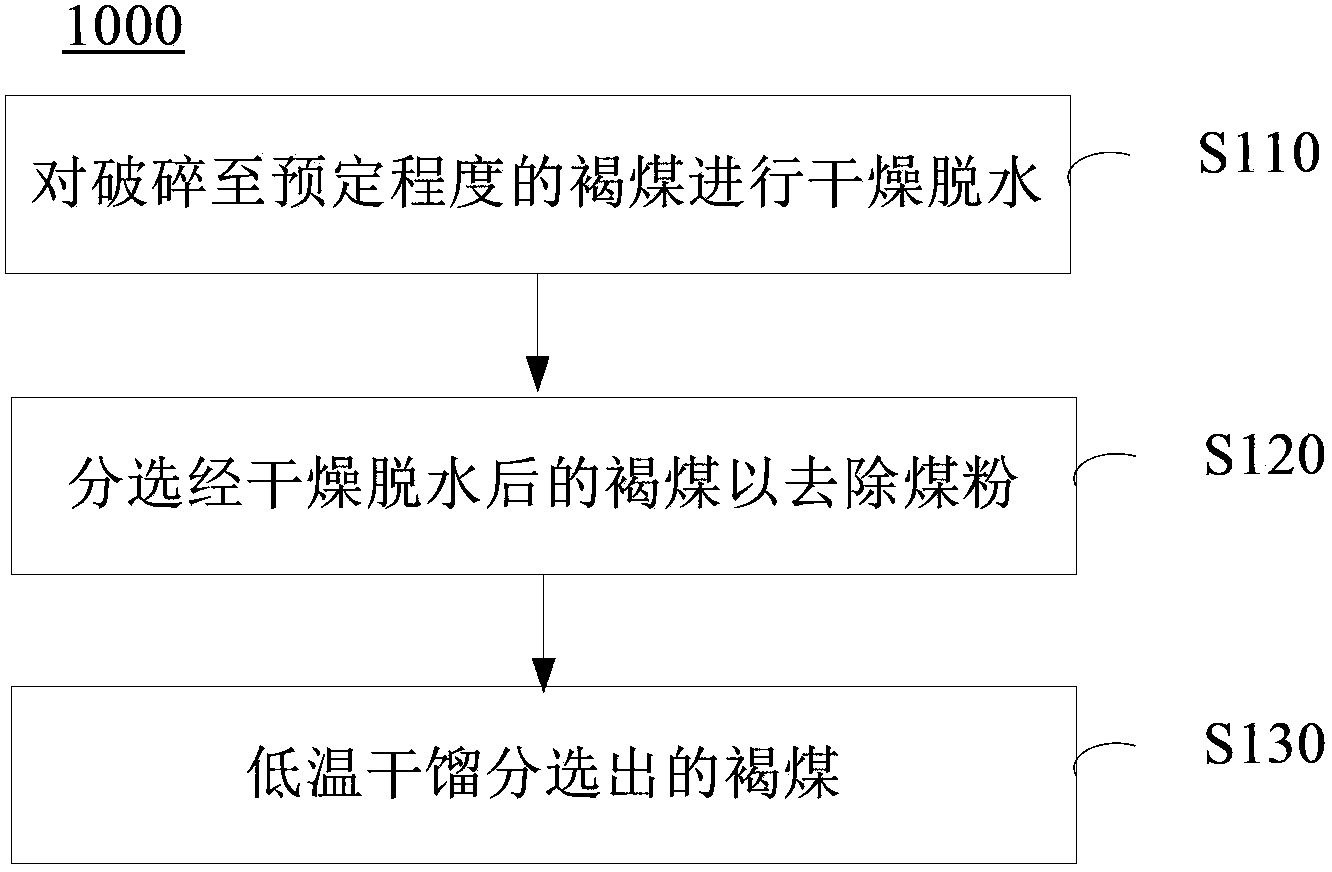

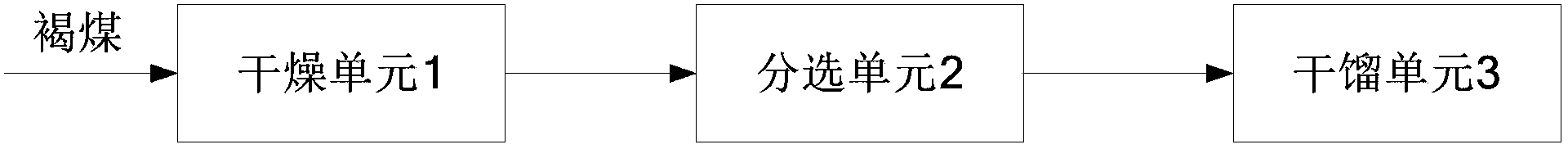

[0014] figure 1 It is a low-rank coal upgrading method 1000 according to an embodiment of the present application. As shown in the figure, in step S110, the lignite crushed to a predetermined degree is dried and dehydrated. For example, after the raw lignite is crushed to a particle size of less than 13mm, it is sent to a drying unit (such as a steam rotary dryer) for drying and upgrading, and the lignite moisture is removed to 8%.

[0015] In step S120, the dried and dehydrated lignite is sorted to remove coal dust. As an option, the dried and dehydrated lignite is subjected to particle size classification using fluidizing wind, and the coal whose sedimentation velocity is lower than the fluidizing wind velocity is removed as coal powder. For example, the dried and upgraded lignite is sent to a sorting unit (such as a fluidized bed winnowing device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com