Grouter with stirring device and control method of grouter

The technology of a grouting machine and a mixing mechanism is applied in the fields of shaft equipment, earthwork drilling, construction material processing, etc., which can solve the problems of occupying human and material resources, difficult grouting equipment, inconvenient operation, etc., and achieve continuous and uniform mortar and sand grains The effect of wide particle size range and easy movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

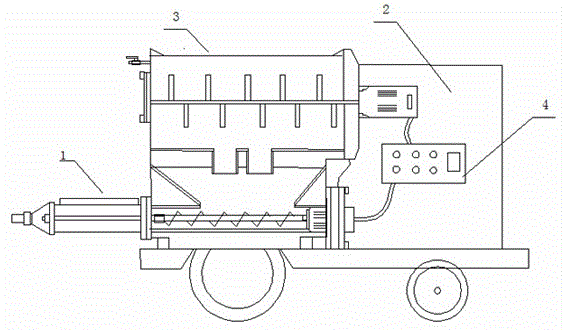

[0044] like figure 1 Shown:

[0045] The invention discloses a grouting machine with a stirring mechanism 3, comprising a single-screw pump 1 fixed on a frame 2 and a stirring mechanism 3, a hopper is arranged under the stirring mechanism 3, the lower part of the hopper is connected with the single-screw pump 1, and The single-screw pump 1 is located below the stirring structure, and the stirring mechanism 3 is suspended relative to the hopper.

[0046] The single-screw pump 1 is fixed on the front part of the frame 2, and includes a grouting head, a booster part, a feeding part, and a grouting motor connected in sequence, and the feeding part is located below the stirring mechanism 3 and connected to the hopper. The grouting head, booster part, feeding part and grouting motor are connected end to end in sequence. The grouting head includes a bucket-shaped grouting cavity, and a pressure gauge is arranged at the outlet of the grouting head for measuring the grouting pressure...

specific Embodiment 2

[0051] The control system based on the grouting machine with the above-mentioned band stirring mechanism 3 includes:

[0052] The sampling and measuring unit is located inside the mixing mechanism 3 and includes a sampler and a measuring instrument. The sampler is a container with an opening, and the measuring instrument is placed in the sampler for sampling the thick concrete slurry in the mixing mechanism 3;

[0053] Stirring unit comprises stirring mechanism 3, and stirring mechanism 3 comprises the stirring box of top opening, the stirring shaft that is arranged on the middle part of stirring box horizontally, the stirring blade that is connected on the stirring shaft, the stirring motor that is connected at the end of stirring shaft; Stir the mixture of concrete and water in the stirring mechanism 3 to a suitable consistency to achieve the set water-cement ratio W / C;

[0054] The conveying unit includes a single-screw pump 1. The single-screw pump 1 includes a grouting he...

specific Embodiment 3

[0061] The concrete control method based on the above-mentioned embodiment 2 grouting machine control system:

[0062] (1) Mix cement and fine sand with a particle size not greater than 3 mm at a ratio of (1.2-1.6): (2.1-2.8) and put them into the mixing tank, start the power supply unit and control unit, and the control unit Control the water injection valve to fully open and inject water into the mixing tank at a flow rate of (30-35) L / min, and then control the stirring motor to rotate reciprocally at 40-50r / min to make concrete thick slurry in the mixing tank;

[0063] (2) The control unit controls the sampling and measuring unit to extract the slurry of the thick concrete slurry and uses the hydrometer water weighing method to measure, and the measured signal is calculated in the control unit to obtain the water-cement ratio W / C value of the thick slurry;

[0064] (3) When the calculated water-cement ratio W / C is lower than or equal to W / C=(0.5-0.55), the control unit cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com