Fe-ni-mo alloy for buzzer and preparation method thereof

A buzzer and alloy technology, applied in the field of alloy materials and their preparation, can solve the problems of precision, hardness, strength and corrosion resistance that are difficult to meet the relevant requirements, and achieve excellent mechanical properties, increase hardness, and fine and uniform grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the examples.

[0026] The preparation process of the Fe-Ni-Mo alloy for the buzzer of the present invention includes: vacuum induction furnace smelting, forging billet opening, hot rolling into a strip billet, cold rolling into a finished product, and then tension straightening and low temperature stress relief annealing.

[0027] Specifically include the following steps:

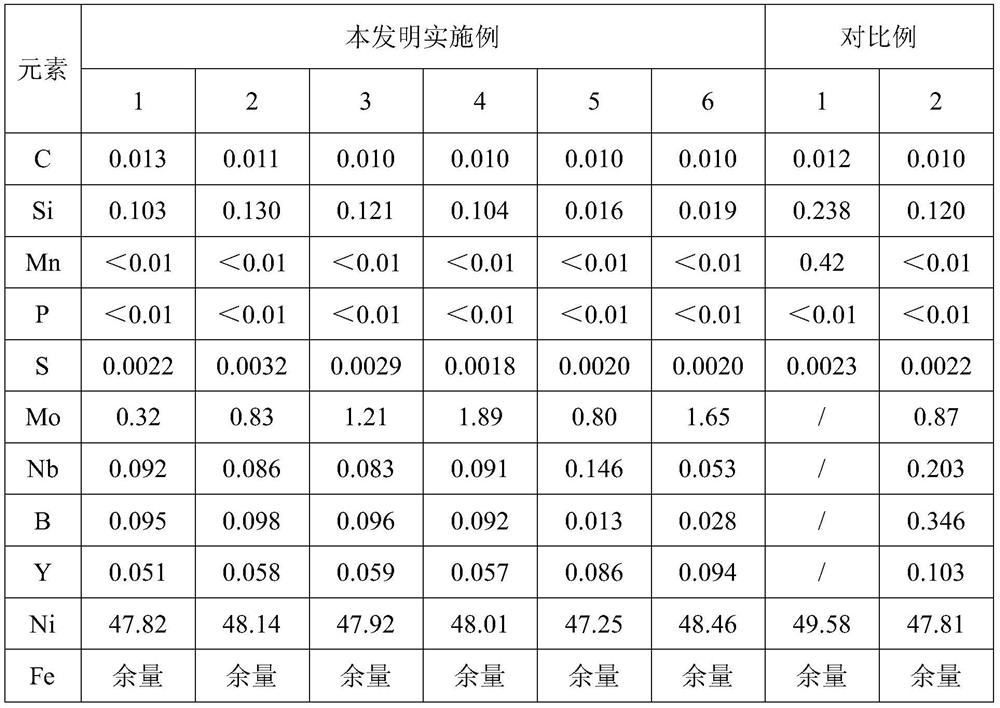

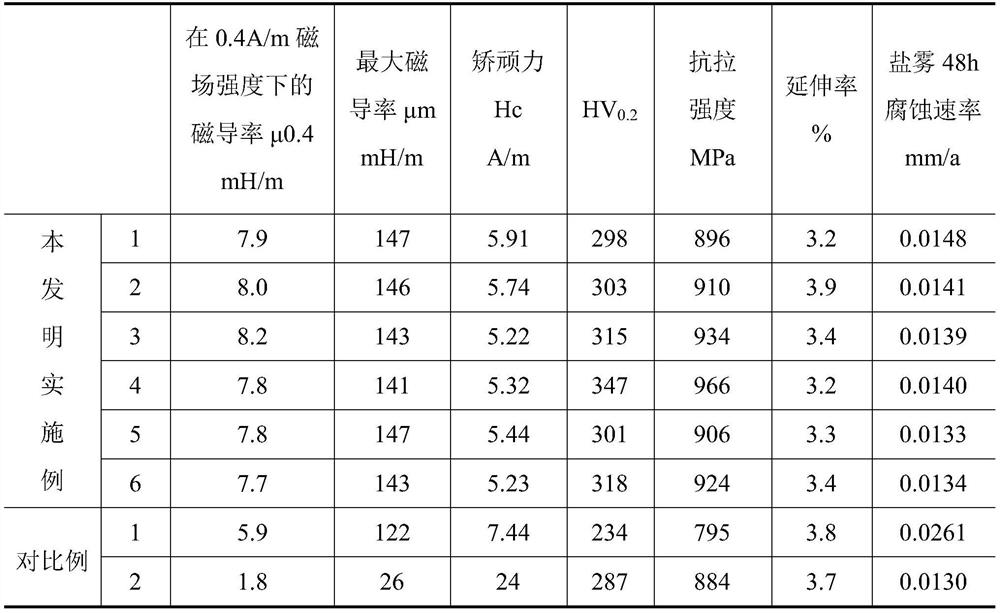

[0028] (1) adopt the composition ratio shown in Table 1 to add raw materials, adopt vacuum induction furnace to smelt, obtain Conical alloy ingots;

[0029] (2) Forging: under the condition of 1100-1180 ℃, heat preservation for 1-1.5 hours, forging into a forging billet of thickness (50-90mm)×width (180-300mm).

[0030] (3) Hot rolling: under the condition of 1100-1170°C, keep warm for 30-60 minutes, and hot-roll into a hot-rolled billet of thickness (5-8mm)×width (180-300mm).

[0031] (4) Cold rolling: multi-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com