Auricularia auricula polysaccharide extracting method

A black fungus polysaccharide and extraction method technology, applied in the field of black fungus polysaccharide extraction, can solve the problems of high equipment requirements, long time consumption, easy inactivation, etc., achieve high economic benefits and avoid high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

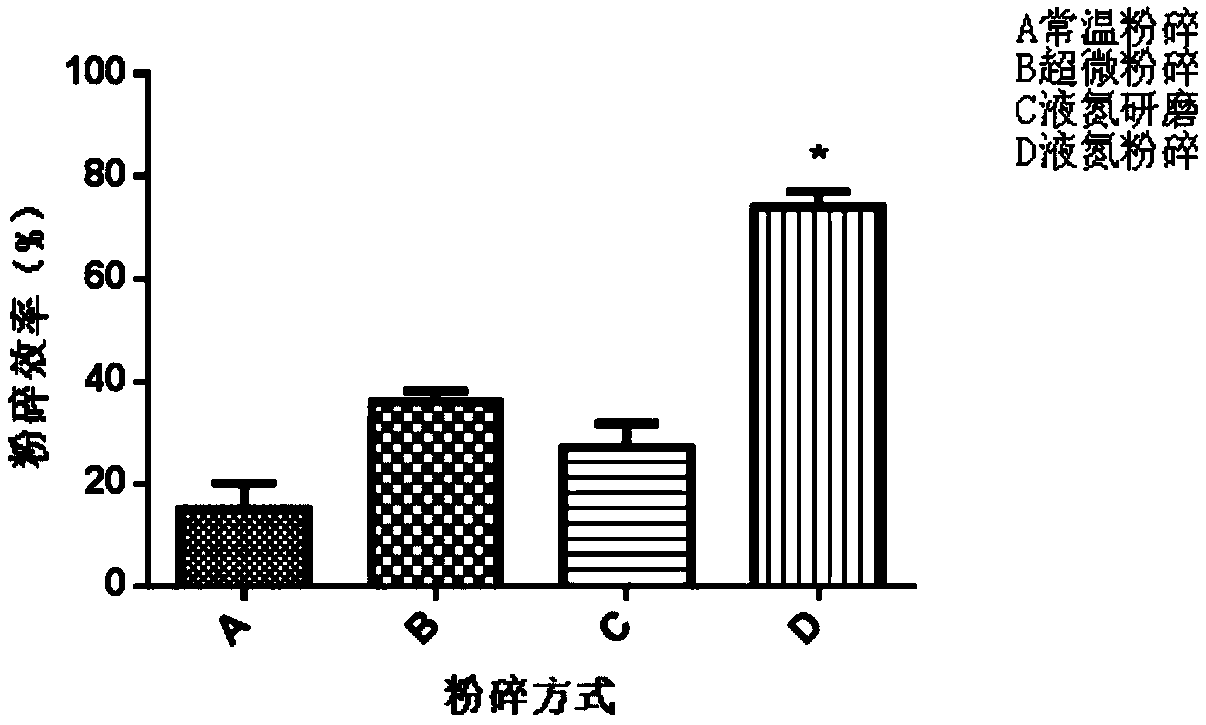

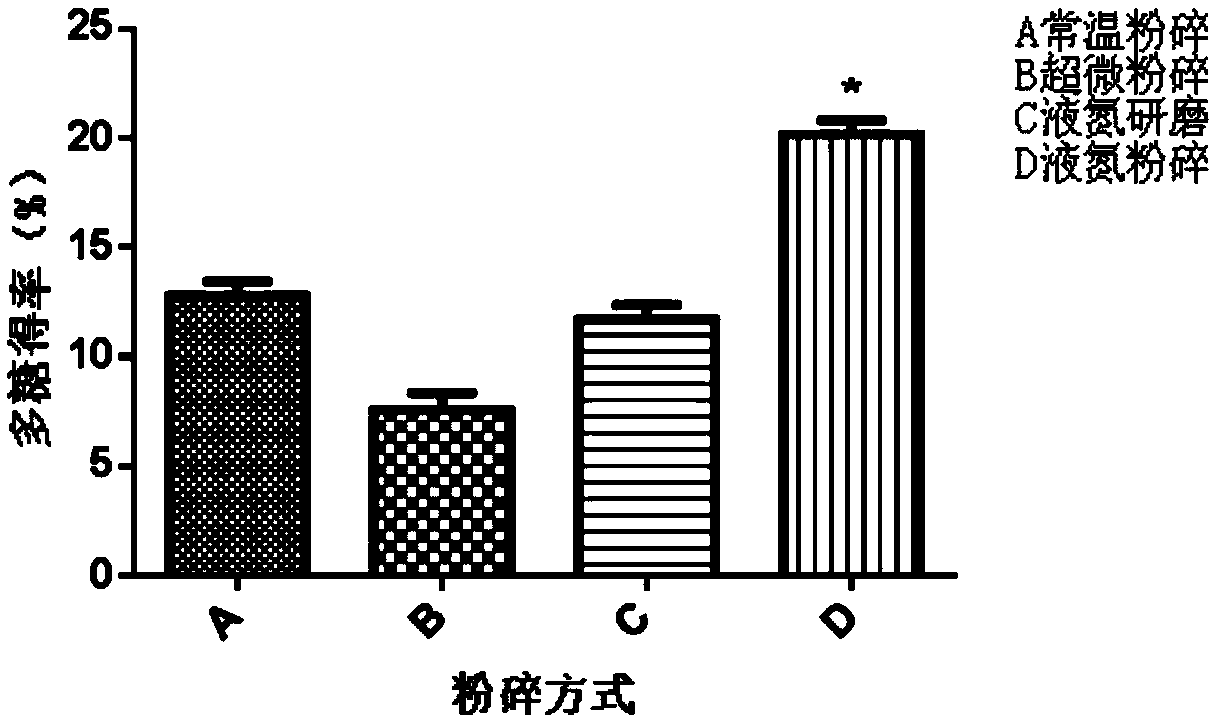

Method used

Image

Examples

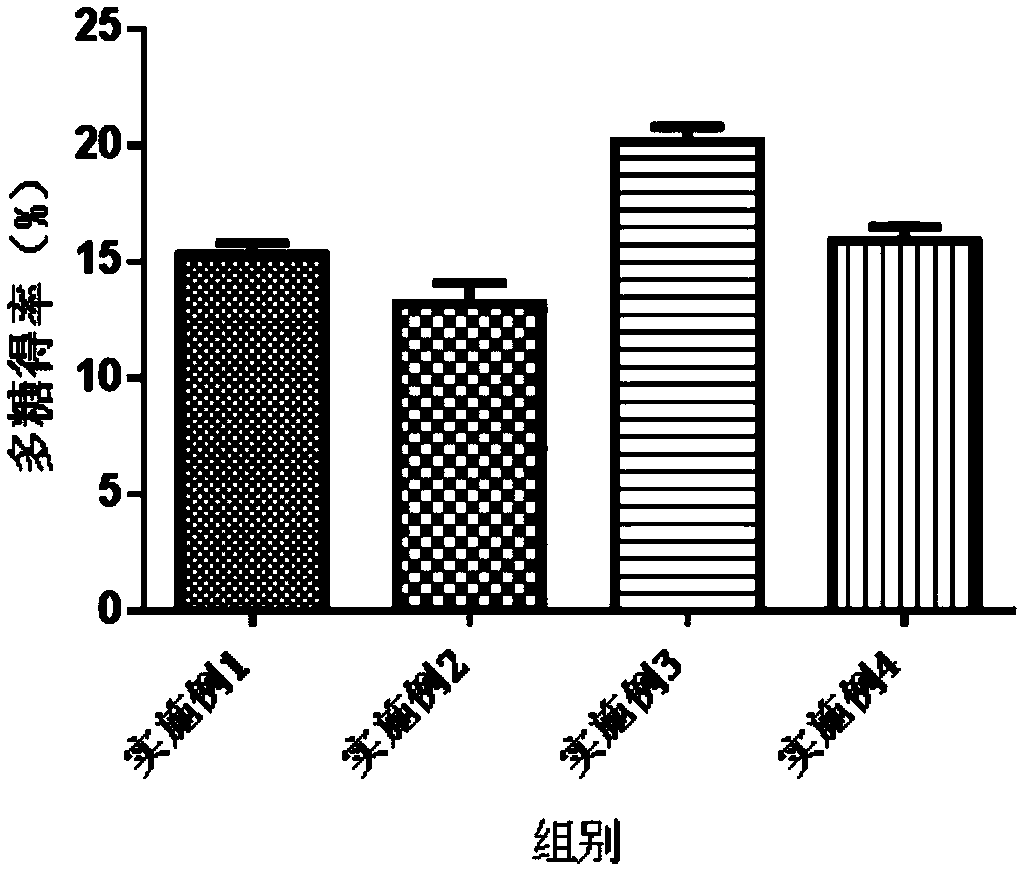

Embodiment 1

[0045] The present embodiment provides a kind of extraction method of black fungus polysaccharide, and this method is carried out according to the following steps:

[0046] 1) drying the black fungus until the water content is 15%, to obtain the pretreated black fungus;

[0047] 2) Put the pretreated black fungus in step 1) into a pulverizer for freezing and crushing. The freezing and pulverizing is to first fill the pulverizer with liquid nitrogen, and then pulverize to obtain black fungus powder; wherein: the amount of liquid nitrogen charged 20% (v / m), the crushing condition is 30000rpm / min, 4min;

[0048] 3) Add water to the black fungus powder obtained in step 2) according to the solid-liquid ratio of 1:60, and perform ultrasonic extraction at 80°C and 300W for 15 minutes. After the extraction, centrifuge at 4500r / min for 6 minutes to take the supernatant Transfer the solution to a 100mL volumetric flask, repeat the above steps for the centrifuged precipitate, and mix th...

Embodiment 2

[0050] The present embodiment provides a kind of extraction method of black fungus polysaccharide, and this method is carried out according to the following steps:

[0051] 1) drying the black fungus until the water content is 1%, to obtain the pretreated black fungus;

[0052]2) Put the pretreated black fungus in step 1) into a pulverizer for freezing and crushing. The freezing and pulverization is to first fill the pulverizer with liquid nitrogen, and then pulverize to obtain black fungus powder; wherein: the filling amount of liquid nitrogen 5% (v / m), the crushing condition is 20000rpm / min, 1min;

[0053] 3) Add water to the black fungus powder obtained in step 2) according to the solid-liquid ratio of 1:20, and perform ultrasonic extraction at 40°C and 100W for 5 minutes. After the extraction, centrifuge at 4500r / min for 6 minutes to take the supernatant Transfer the solution to a 100mL volumetric flask, repeat the above steps for the centrifuged precipitate, and mix the ...

Embodiment 3

[0055] The present embodiment provides a kind of extraction method of black fungus polysaccharide, and this method is carried out according to the following steps:

[0056] 1) drying the black fungus to a water content of 10% to obtain pretreated black fungus;

[0057] 2) Put the pretreated black fungus in step 1) into a pulverizer for freezing and crushing. The freezing and pulverization is to first fill the pulverizer with liquid nitrogen, and then pulverize to obtain black fungus powder; wherein: the filling amount of liquid nitrogen 15% (v / m), the crushing condition is 25000rpm / min, 2min;

[0058] 3) Add water to the black fungus powder obtained in step 2) according to the solid-liquid ratio of 1:50, and perform ultrasonic extraction at 60°C and 180W for 9 minutes. After the extraction, centrifuge at 4500r / min for 6 minutes to take the supernatant Transfer the solution to a 100mL volumetric flask, repeat the above steps for the centrifuged precipitate, and mix the two sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com