Method for preparing high-purity low-oxygen chromium metal powder

A technology of metal chromium powder and metal chromium, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of high cost and complex production process of chromium powder, achieve low cost, realize mass production, and reduce oxygen content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

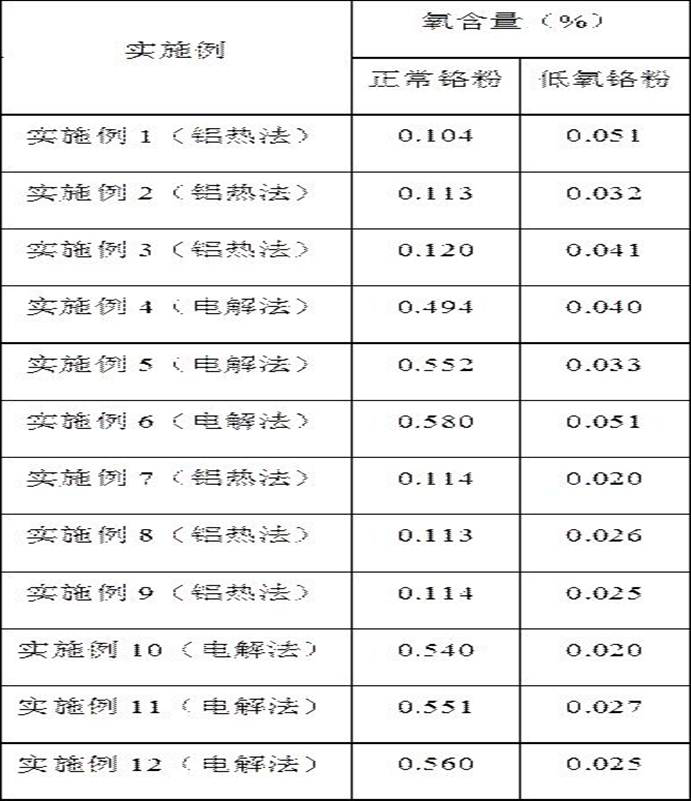

Examples

Embodiment 1

[0031] A preparation method of high-purity low-oxygen metal chromium powder, comprising the following steps:

[0032] Preparation of raw materials for S1 chromium powder: manual roughing of impurities in the aluminothermic metal chromium with a purity of 99.5%, picking out the inclusions and oxides visible to the naked eye on the chromium surface, reducing the impurity content in the newly prepared chromium powder, and the pretreated metal Chromium is powdered by low-temperature grinding and crushing method, and the low-temperature brittleness of chromium is used to grind and crush it to make powder;

[0033] S2 powder mixing: the chromium powder raw material with a particle size of 40 mesh is selected by screening, graphite powder is added thereto, and mixed material is obtained after fully mixing. The particle diameter of the graphite powder is less than 2000 mesh, and the purity of the graphite powder is 99.92%. Step S1 The sintering of chromium powder raw material and grap...

Embodiment 2

[0043] A preparation method of high-purity low-oxygen metal chromium powder, comprising the following steps:

[0044] S1 Chromium powder raw material preparation: Manually select the impurities in the thermite metal chromium with a purity of 99.35%, pick out the inclusions and oxides visible to the naked eye on the chromium surface, reduce the impurity content in the newly prepared chromium powder, and the pretreated metal Chromium is powdered by low-temperature grinding and crushing method to obtain raw material of chromium powder. Utilize the low-temperature brittleness of chromium to grind and pulverize it to make powder;

[0045] S2 mixed powder: sieve and select the chromium powder raw material with a particle size of 250 mesh, add graphite powder therein, and obtain the mixed material after fully mixing, the particle diameter of the graphite powder is less than 2000 mesh, and the purity of the graphite powder is 99.93%. The sintering of raw material and graphite powder ...

Embodiment 3

[0055] A preparation method of high-purity low-oxygen metal chromium powder, comprising the following steps:

[0056] Preparation of raw materials for S1 chromium powder: manual roughing of impurities in the thermite metal chromium with a purity of 99.4%, picking out inclusions and oxides visible to the naked eye on the chromium surface, reducing the impurity content in the newly prepared chromium powder, and the pretreated metal Chromium is powdered by low-temperature grinding and crushing method to obtain raw material of chromium powder. Utilize the low-temperature brittleness of chromium to grind and pulverize it to make powder;

[0057] S2 powder mixing: sieve and select the chromium powder raw material with a particle size of 500 mesh, add graphite powder to it, and mix thoroughly to obtain a mixed material. The particle diameter of the graphite powder is less than 2000 mesh, and the purity of the graphite powder is 99.95%. After raw material and graphite powder are mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com