Process for preparing edible bird's nest extraction used for cosmetics

A preparation process and extract technology, which is applied in the field of preparation of bird's nest extract for cosmetics, can solve the problems that the method of ultrasonic extraction and alkaline protease, the relationship between extraction process and molecular weight distribution have not been clarified, and achieve molecular weight Reasonable distribution, short production cycle and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

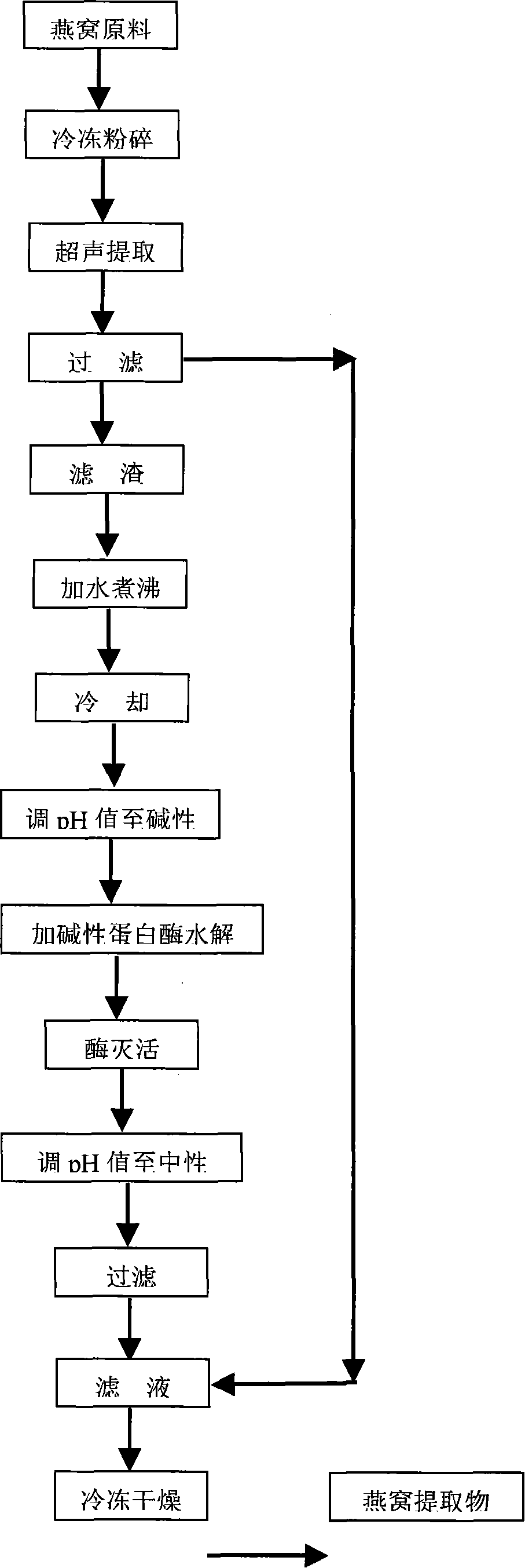

Method used

Image

Examples

Embodiment 1

[0017] Pass the frozen and pulverized bird’s nest through a 100-mesh sieve, weigh 100g of bird’s nest powder, add 2500ml of water, extract it with ultrasonic water for 1 hour at room temperature, filter, and freeze-dry the filtrate to obtain 1.74g of powdery bird’s nest extract, with a yield of 1.74% . The molecular weight distribution of the product is determined, wherein the content above 10,000 Daltons accounts for 84.34%, and the content of 2,000-6,000 Daltons accounts for 4.38%. According to pharmacological experiments, it has excellent whitening activity and good moisturizing effect.

Embodiment 2

[0019] The frozen and pulverized bird's nest passed through a 100-mesh sieve, weighed 100g of bird's nest powder, added 2500ml of water, ultrasonically extracted for 1 hour at room temperature, then added water with a dry weight of bird's nest of 4000ml, and kept boiling for 20 minutes. Then cooled to room temperature, with 2% Na by weight 2 CO 3 Adjust the pH of the solution to 8.5, add 0.5 g of alkaline protease with an enzyme activity range of 1.5 million u / g, and hydrolyze for 1 hour under mechanical stirring and a temperature of 50°C. The hydrolyzate was inactivated at 85°C for 20 minutes. Then cool to room temperature, use 1% by weight of dilute HCl to adjust the pH value to neutral, filter, combine the filtrate after enzymolysis with the ultrasonic extract, and freeze-dry to obtain 79g of powdery bird's nest extract, with a yield of 79%. . The molecular weight distribution of the product is determined, wherein the content above 10,000 Daltons accounts for 7.2%, and t...

Embodiment 3

[0021] The frozen and pulverized bird's nest was passed through a 100-mesh sieve, weighed 100g of bird's nest powder, added 2500ml of water, ultrasonically extracted for 1 hour at room temperature, filtered, and the filtrate was discarded. Add 4000ml of water with a dry weight of bird's nest to the filter cake and keep boiling for 20 minutes. Then cooled to room temperature, with 2% Na by weight 2 CO 3 Adjust the pH of the solution to 8.5, add 0.5 g of alkaline protease with an enzyme activity range of 1.5 million u / g, and hydrolyze for 1 hour under mechanical stirring and a temperature of 50°C. The hydrolyzate was inactivated at 85°C for 20 minutes. Then cool to room temperature, adjust the pH value to neutral with 1% by weight of dilute HCl, filter, and freeze-dry the filtrate after enzymolysis to obtain 75 g of powdered bird's nest extract, with a yield of 75%. The molecular weight distribution of the product is determined, wherein the content above 10,000 Daltons accoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com