Porous coarse cereal flour including dietary fibers

A technology for dietary fiber and miscellaneous grain powder, which is applied in the field of food processing, can solve problems such as the inability to meet the diverse needs of food, and achieve the effects of protecting intestinal health, improving brewing performance, and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

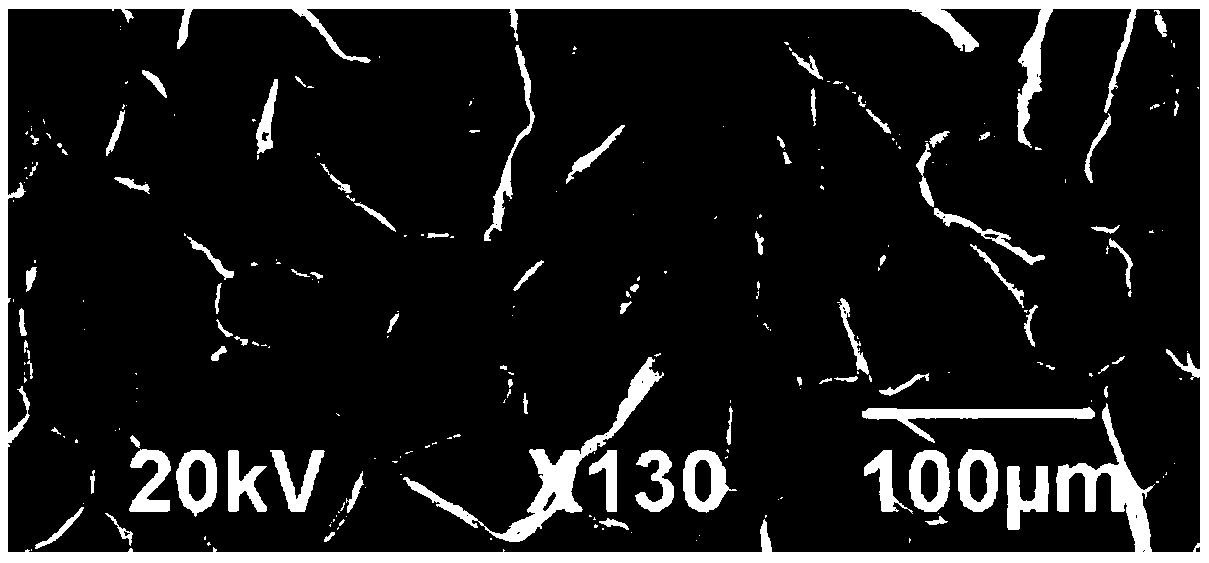

Image

Examples

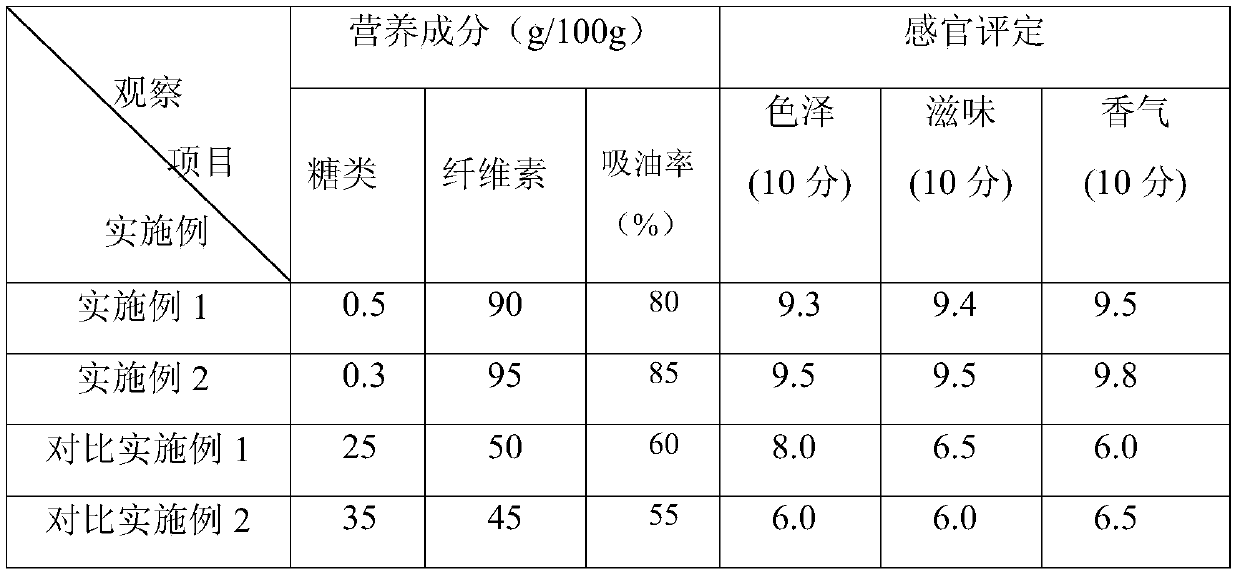

Embodiment 1

[0027] 1) Take 300g of mung bean husks, 100g of corn husks, and 100g of sorghum husks, clean them and dry them; soak them in 60% glycolic acid aqueous solution, and control the pH of the glycolic acid aqueous solution to 3.0, and put them into an ultrasonic cleaner Wash for 50 minutes;

[0028] 2) drying the cleaned miscellaneous grain shells, and pulverizing them into powder;

[0029] 3) Take 100g of fresh pumpkin skin dregs, 100g of sweet potato skin dregs, 100g of kudzu root dregs, 100g of yam skin dregs, 100g of lotus root skin dregs, wash, smash, and blanch in boiling water for 8 minutes, cool and keep the temperature at 30°C, add the peel 0.5% amylase in slag quality, enzymatic hydrolysis for 60 minutes, and then deenzyme; inoculate 0.07‰ yeast and 0.02‰ lactic acid bacteria for fermentation, fermentation temperature 25°C, aerobic fermentation for 3 days, anaerobic fermentation for 17 days, fermentation environment humidity 85%;

[0030] 4) cleaning and filtering the f...

Embodiment 2

[0033] Embodiment 2, with embodiment 1, difference is,

[0034] 1) Take 150g of mung bean husks, 50g of corn husks, and 50g of sorghum husks, clean them and dry them; soak them in 65% glycolic acid aqueous solution, and control the pH of the glycolic acid aqueous solution to 4.0, and put them into an ultrasonic cleaner Wash for 40 minutes;

[0035] 3) Take 50g of fresh pumpkin skin dregs, 50g of sweet potato skin dregs, 50g of kudzu root dregs, 50g of yam skin dregs, and 50g of lotus root skin dregs, wash them, break them up, blanch them in boiling water for 12 minutes, cool and keep the temperature at 35°C, add the peels 0.3% amylase in slag quality, enzymatic hydrolysis for 70 minutes, and then inactivate the enzyme; inoculate 0.05‰ yeast and 0.01‰ lactic acid bacteria in the dregs quality for fermentation, fermentation temperature 23°C, aerobic fermentation for 4 days, anaerobic fermentation for 20 days, fermentation environment humidity 85%;

[0036] 5) Take 50 g of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com