Hot rolling aluminium alloy for bottle cap material and producing method thereof

A production method and technology of aluminum alloy, applied in metal rolling and other directions, can solve the problems of high ear rate, uneven tensile strength, etc., and achieve the effects of improving production efficiency, reducing material consumption and energy consumption, and achieving excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

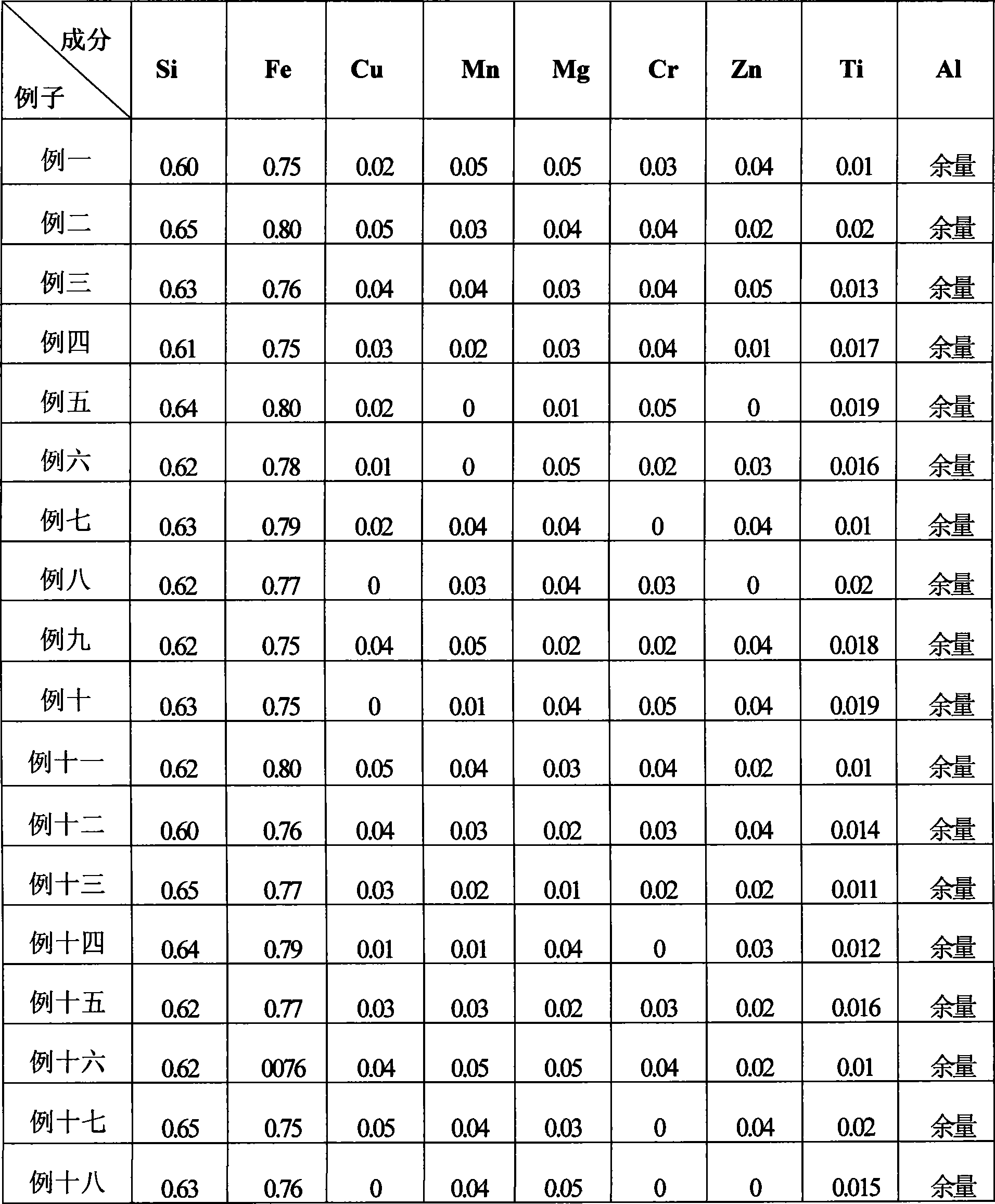

[0023] Embodiment 1. An aluminum alloy for bottle cap material, expressed in parts by weight, the ingredients are shown in Table 2, and the total of each ingredient is 100 parts. If there are impurities, the content of individual impurity components is required to be less than 0.03 parts, and the total impurity content to be less than 0.10 parts.

[0024] The production method of aluminum alloy for bottle cap material comprises the following steps:

[0025] (1) Smelting: add various components to the melting furnace by weight, melt at 720-740°C, and cast aluminum alloy ingots at 715-725°C after all the charge is melted;

[0026] (2) Ingot face milling: milling the aluminum alloy ingot, requiring a single-sided milling amount ≥ 15mm, the thickness difference between the two sides of the ingot ≤ 3mm, and the roughness of the milling surface required to be 0.06-0.15mm;

[0027] (3) Ingot heating: heat the aluminum alloy ingot after face milling to 540-560°C, heat it for 6-10 hou...

Embodiment 2

[0036] Embodiment two, the aluminum alloy composition of bottle cap material is shown in Table 2, and its production method is no longer repeated with the same part as embodiment one, and the difference is:

[0037] (1) Melting: The charge composition is smelted at 730°C, and when the charge is completely melted, it is cast into an aluminum alloy ingot at 720°C;

[0038] (2) Ingot heating: heat the aluminum alloy ingot after face milling to 545°C, hold it for 8 hours, and release it from the furnace; the furnace temperature is 510°C;

[0039] (3) Cold rolling and finishing: when rolling to 1.2mm, intermediate annealing is carried out, and the intermediate annealing is degreased at a furnace temperature of 245°C for 6 hours; then at a furnace temperature of 450°C, it is kept for 13 hours; When the temperature is 405°C, keep it warm for 2 hours, then take it out of the furnace and cool it in air; when the rolling reaches 0.46mm, then perform intermediate annealing, the method is...

Embodiment 3

[0040] Embodiment three, the aluminum alloy composition of bottle cap material is shown in Table 2, and its production method is no longer repeated with the same part as embodiment one, and the difference is:

[0041] (1) Smelting: The charge composition is smelted at 735°C, and when the charge is completely melted, it is cast into an aluminum alloy ingot at 720°C;

[0042] (2) Ingot heating: heat the aluminum alloy ingot after face milling to 560°C, keep it warm for 6 hours, and release it from the furnace; the furnace temperature is 515°C;

[0043] (3) Cold rolling and finishing: when rolling to 1.2mm, intermediate annealing is carried out, and the intermediate annealing is degreased at a furnace temperature of 250°C for 6 hours; then at a furnace temperature of 450°C, it is kept for 13 hours; When the temperature is 405°C, keep it warm for 2 hours, and cool it out of the furnace; when rolling to 0.46mm, perform intermediate annealing, the method is the same as the first tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com