Grinding and extracting device

An extraction device and grinding body technology, applied in the grinding field, can solve the problems of reduced juice drop efficiency, filter blockage, low extraction efficiency, etc., and achieve the effects of improving the filtering effect, facilitating cleaning, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

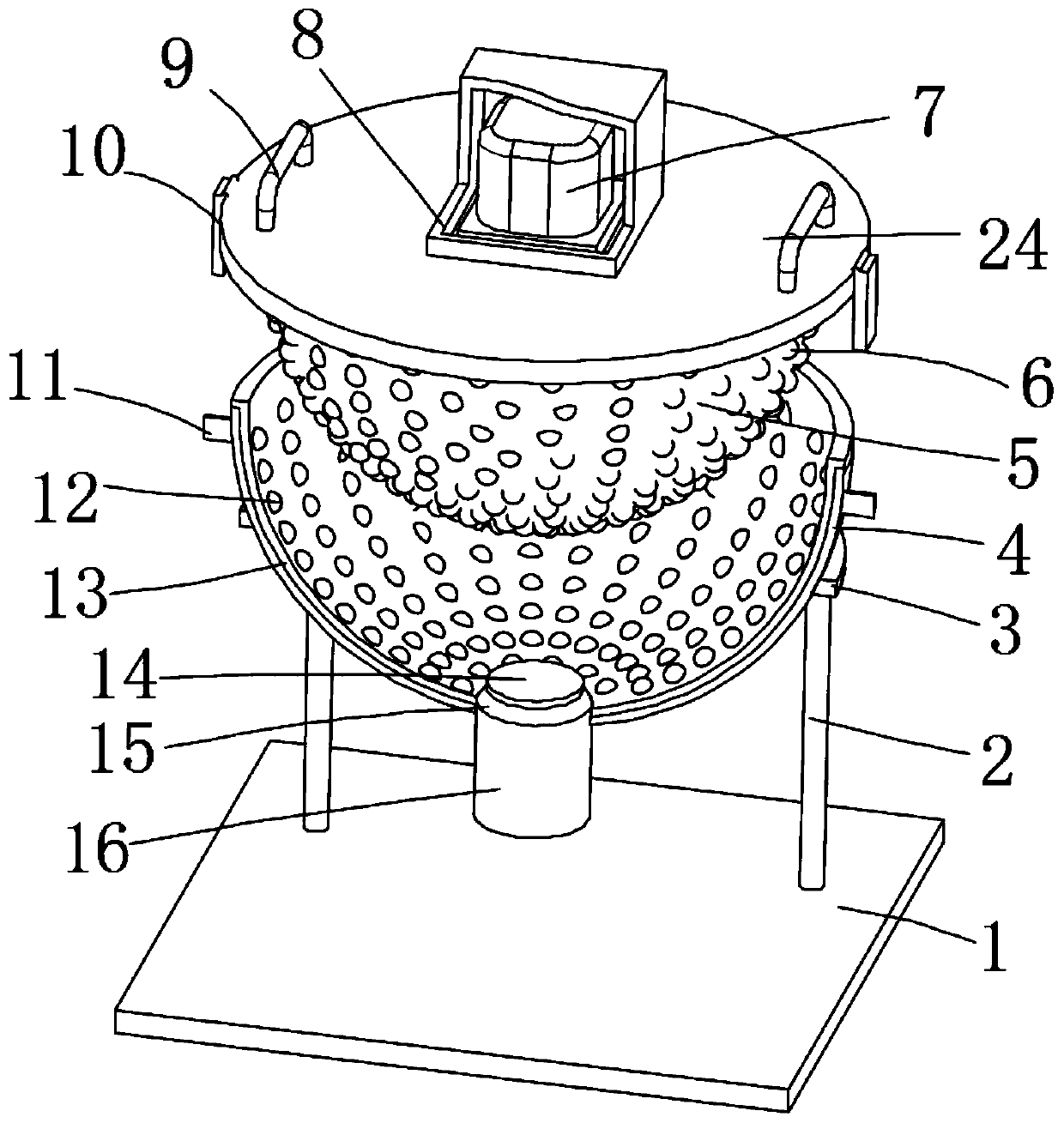

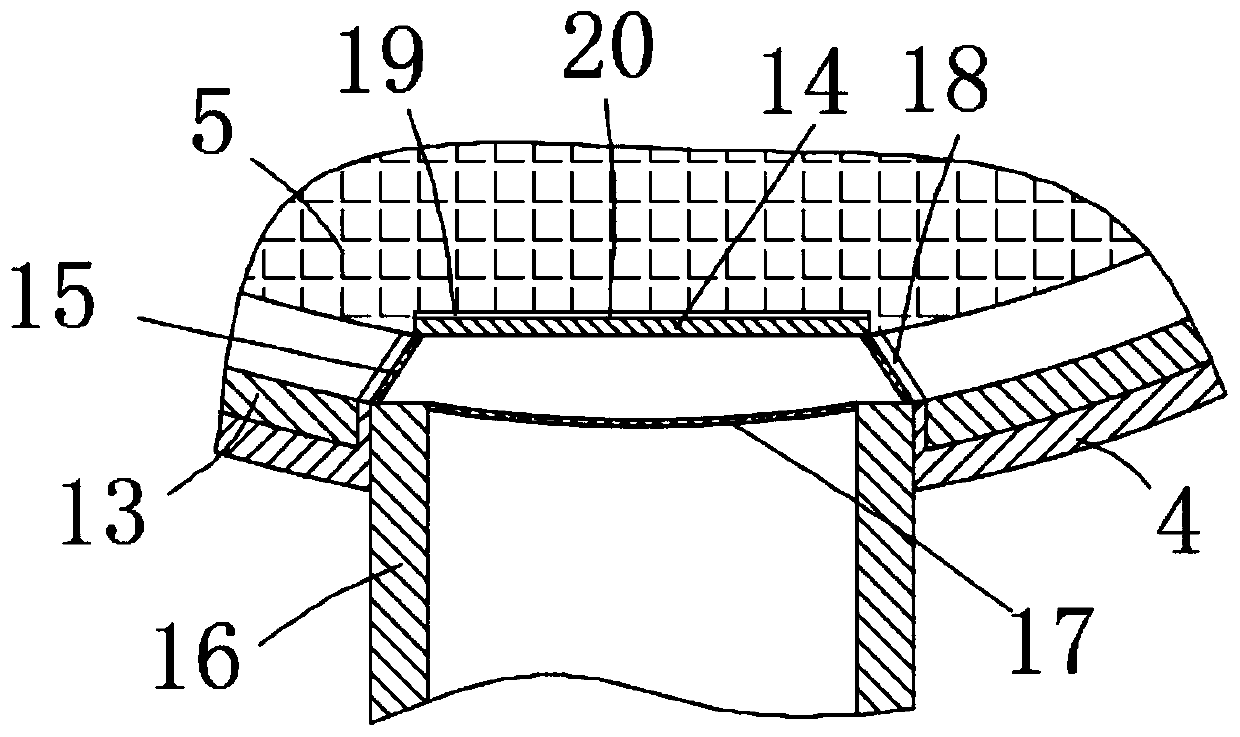

[0029] A grinding extraction device, such as figure 1 , figure 2 and Figure 4 As shown, the outer shell 4 and the shell cover 24 are included, the inner shell 13 is placed on the top outer wall of the outer shell 4, and the side inner wall of the inner shell 13 is provided with fixed grinding balls 12, and the top inner wall of the shell cover 24 is connected by a bearing. There is a grinding body 5, the side outer wall of the grinding body 5 is provided with movable grinding balls 6 dislocated with the fixed grinding balls 12, the outer wall of the bottom of the outer shell 4 is provided with a liquid outlet, and the side inner wall of the liquid outlet is connected by a screw thread. The liquid cylinder 16, the top outer wall of the liquid outlet cylinder 16 is welded with a filter screen ring 15, and the bottom outer wall of the grinding body 5 is welded with two annular evenly distributed scrapers 18. Contact, the top outer wall of shell cover 24 is connected with moto...

Embodiment 2

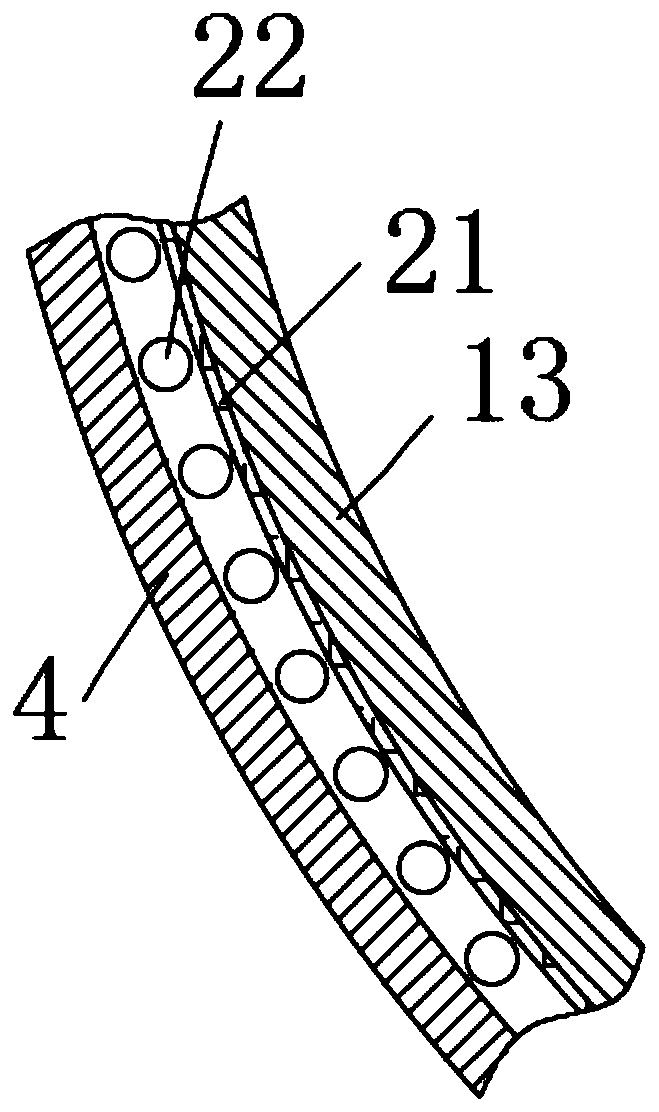

[0037] A grinding extraction device, as shown in 3, in order to improve the effect of plant juice extraction; this embodiment makes the following improvements on the basis of embodiment 1: the side wall of the outer shell 4 has a groove, and the side of the groove A heat conduction shell 21 is welded on the inner wall, and a heating wire 22 is connected between the heat conduction shell 21 and the outer shell 4 through staples, and a temperature control system is externally connected to the heat conduction wire 22 .

[0038] When this embodiment is in use, compared with Embodiment 1, the heating wire 22 can heat the heat-conducting shell 21, and then can heat the inner shell 13, so that the tissue fibers of the plant can be softened, making the juice easier to separate out. Improved extraction performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com