Method for forging large bevel tee

An oblique tee, large-scale technology, applied in the field of forging technology, can solve the problems of increased processing difficulty, difficult to control precision, and eccentric hole drilling errors, etc., to achieve the effects of easy processing, improved quality, and guaranteed processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

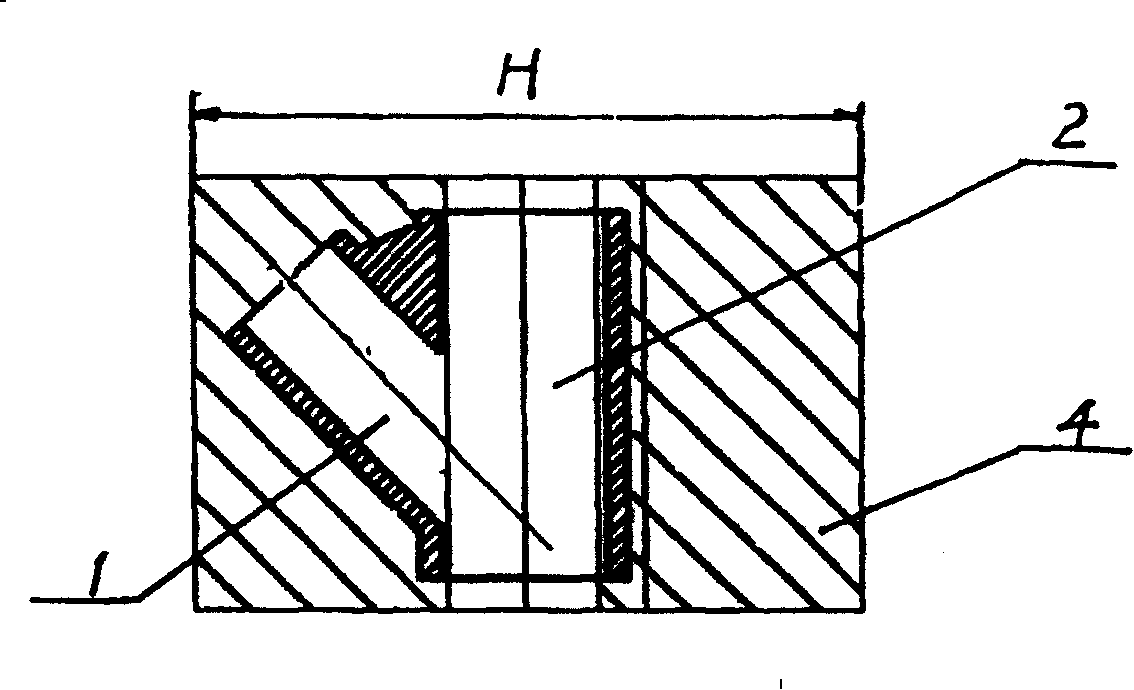

[0015] Such as figure 2 Shown, is the schematic diagram of forging method of large-scale oblique tee of the present invention, the forging method of large-scale oblique tee of the present invention is:

[0016] Step 1. Select a rectangular forging blank 4, the height H of the rectangle is twice the height from the farthest end of the inclined pipe 1 to the centerline of the inner hole of the main pipe 2, so that the inner hole of the main pipe 2 becomes the center of the rectangular forging 4 Hole, leaving machining allowance;

[0017] Step 2. Machining the central hole of the rectangular forging blank 4, which becomes the inner hole of the main pipe part 2;

[0018] Step 3. Saw off the remaining pieces of the process on one side of the main pipe part 2 with a band sawing machine;

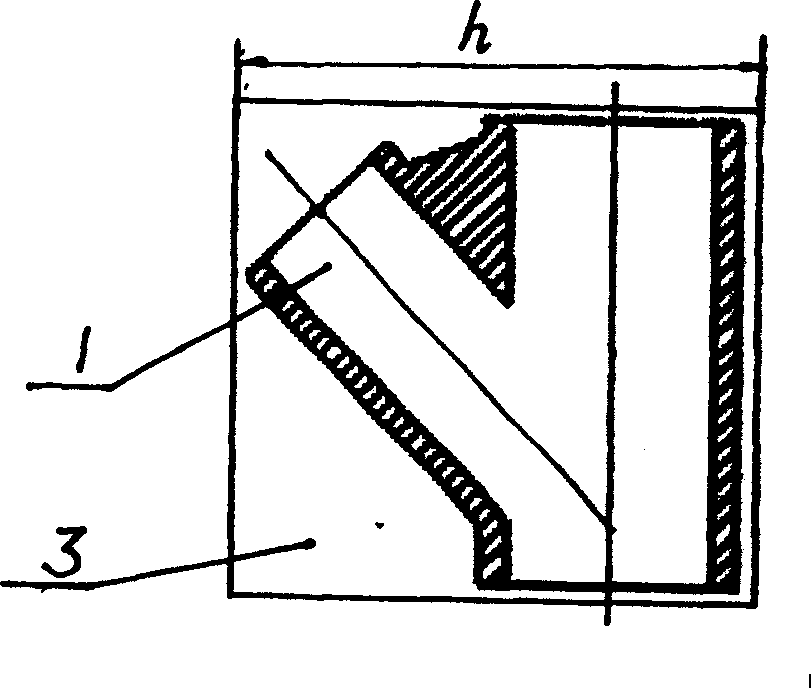

[0019] Step 4. Process the inclined pipe fitting 1 again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com