Welding method of maritime crane barrel neck opening

A welding method and crane technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing welding workload, difficult to control deformation, unfavorable promotion, etc., to reduce machining workload, improve qualification rate, The effect of promoting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The welding method of the neckline of the marine crane barrel includes the following steps:

[0052] A. Welding raceway plate 1:

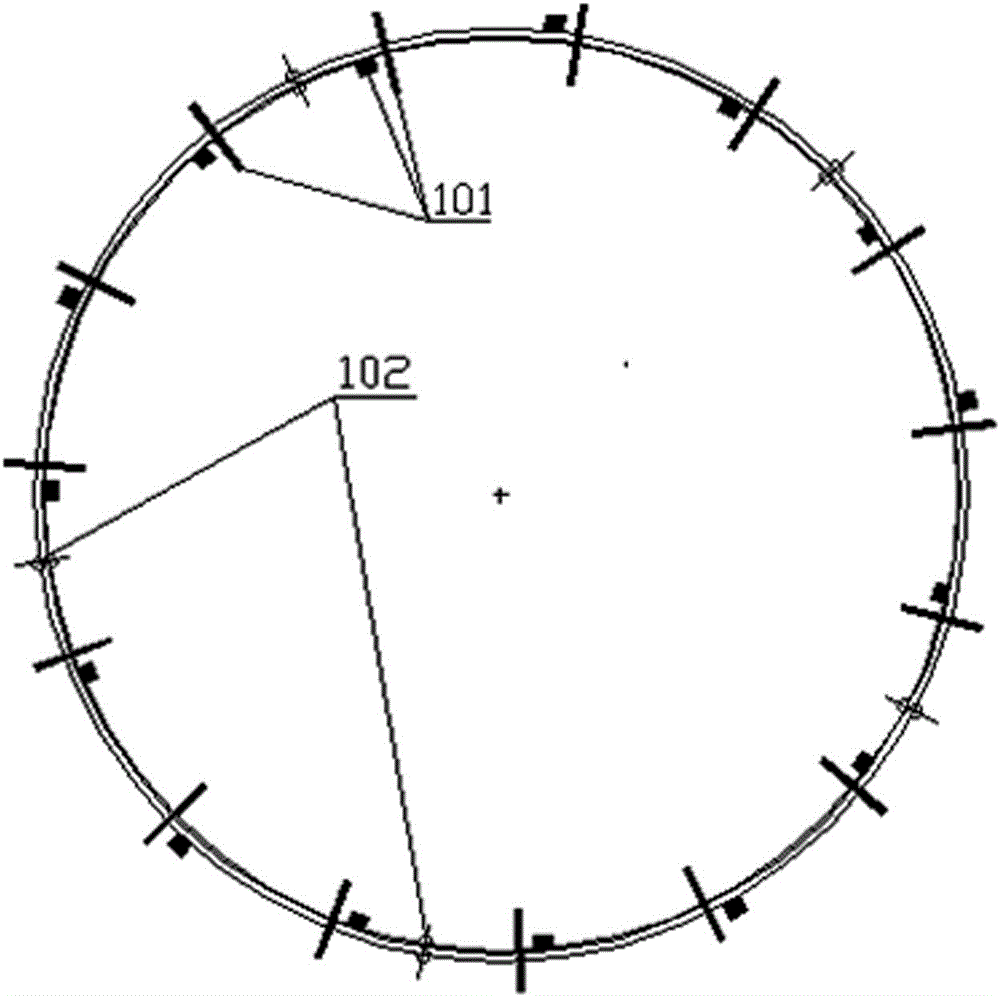

[0053] 1) if figure 1 As shown, make the tire frame 101 for welding the raceway plate, lift the five-section raceway plate to the tire frame, and position it to ensure that the positive tolerance is ?10160 ;

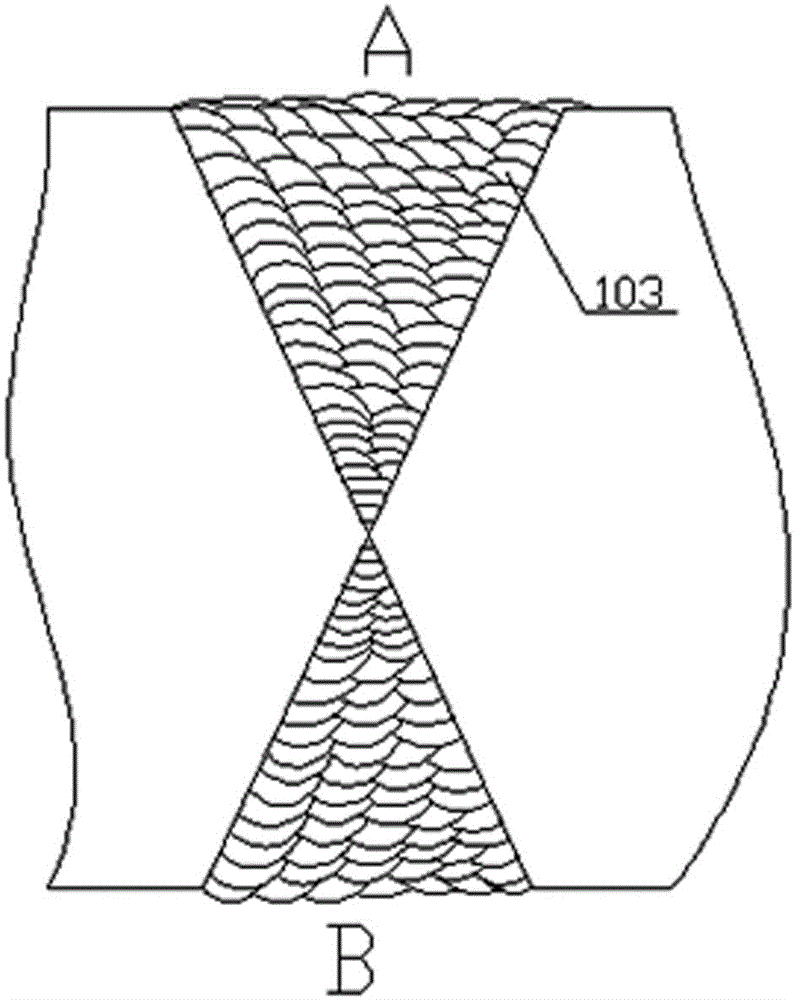

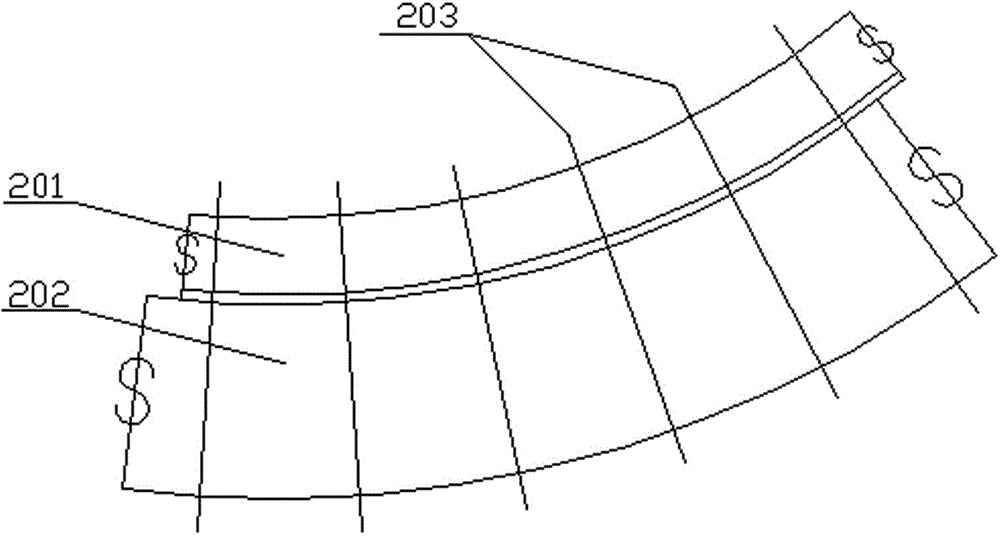

[0054] 2) The height of the raceway plate 1 is 1260mm. During the welding process, it is easy to form a cone. In order to ensure that the vertical straightness is less than 2, it is necessary to de-weld the five joints 102 at the joint of the raceway plate 1 at the same time. More, the tack welding is on the outside, with a round steel transition, and the upper and lower ends of the seam 102 are equipped with guide and arc extinguishing plates, such as figure 2 Shown: Weld 2 / 3 of the inner side A of the tailor seam 102 first, then clean up and check the outer side B, then weld the outer side B of the tailor seam 102, and finally w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com