Rolling piston and manufacturing method thereof for rotary type cold compressor

A technology of refrigeration compressors and rolling pistons, which is applied to rotary piston/oscillating piston pump components, machines/engines, mechanical equipment, etc., and can solve problems affecting the health of operators, complicated manufacturing processes, and high manufacturing costs. Achieve the effects of avoiding pollution and high energy consumption, low roughness, and small frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

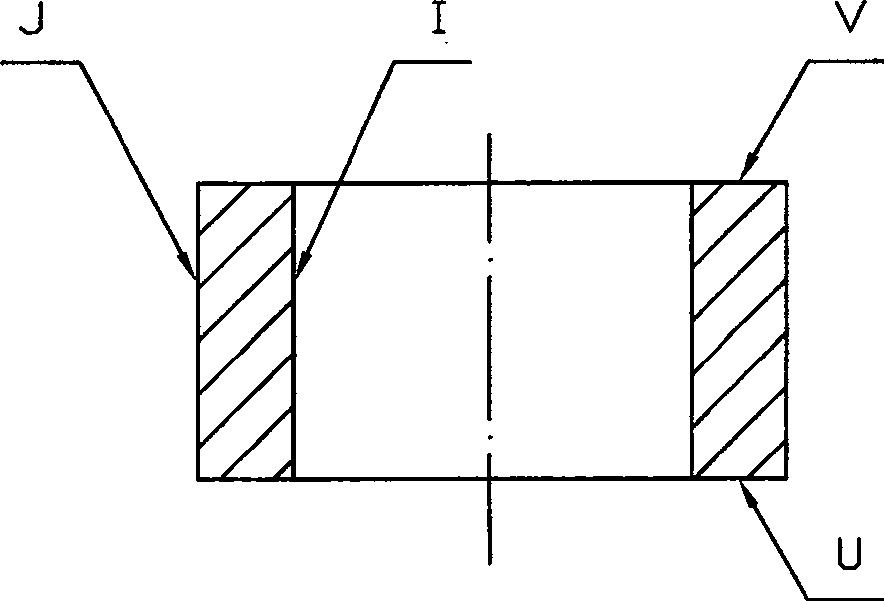

[0026] A rolling piston for a rotary refrigeration compressor, the piston material is a precision steel pipe after cold rolling of GCr15 bearing steel.

[0027] A method for manufacturing a rolling piston for a rotary refrigeration compressor, comprising the steps of:

[0028] (1) Select GCr15 bearing steel and cold-roll it into a precision steel pipe that meets the precision required by the rolling piston;

[0029] (2) Cutting the steel pipe to the required rolling piston ring material length by turning or milling;

[0030] (3) Heat treatment of rolling piston ring material with controllable gas;

[0031] (4) Rolling piston ring material rolling and deburring;

[0032] (5) Coarsely grinding each surface of the rolling piston ring material;

[0033] (6) Thermally stabilized rolling piston ring material:

[0034] (7) Finely grind each surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com