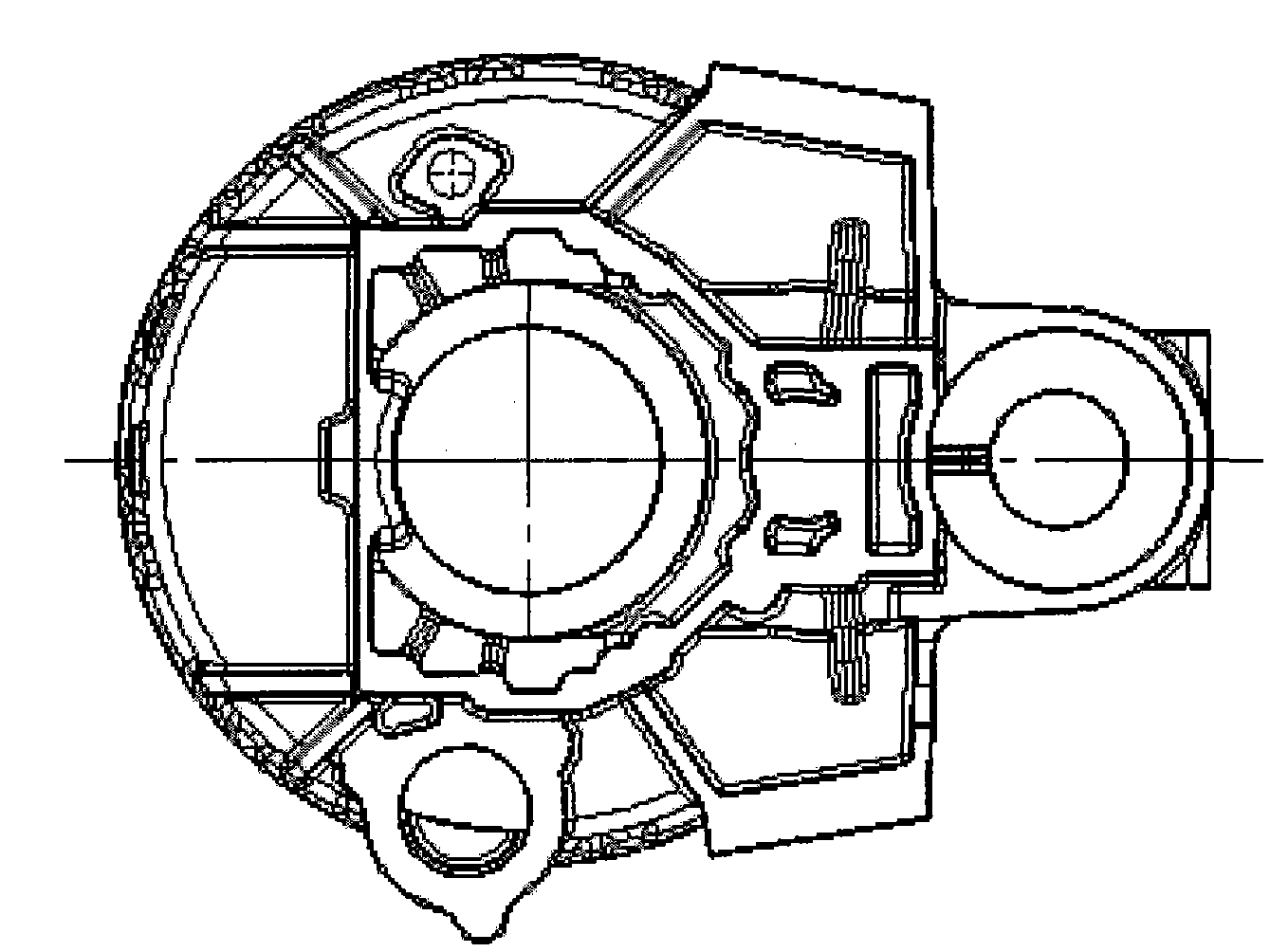

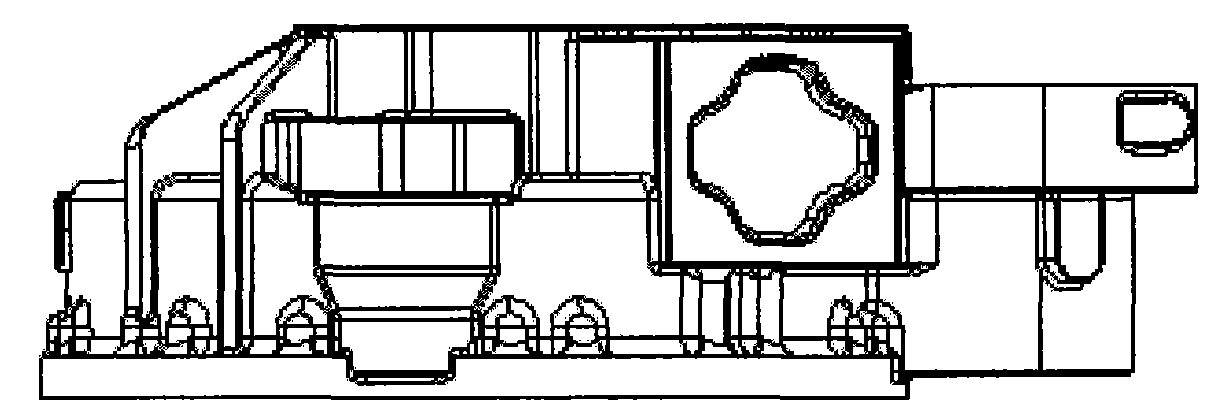

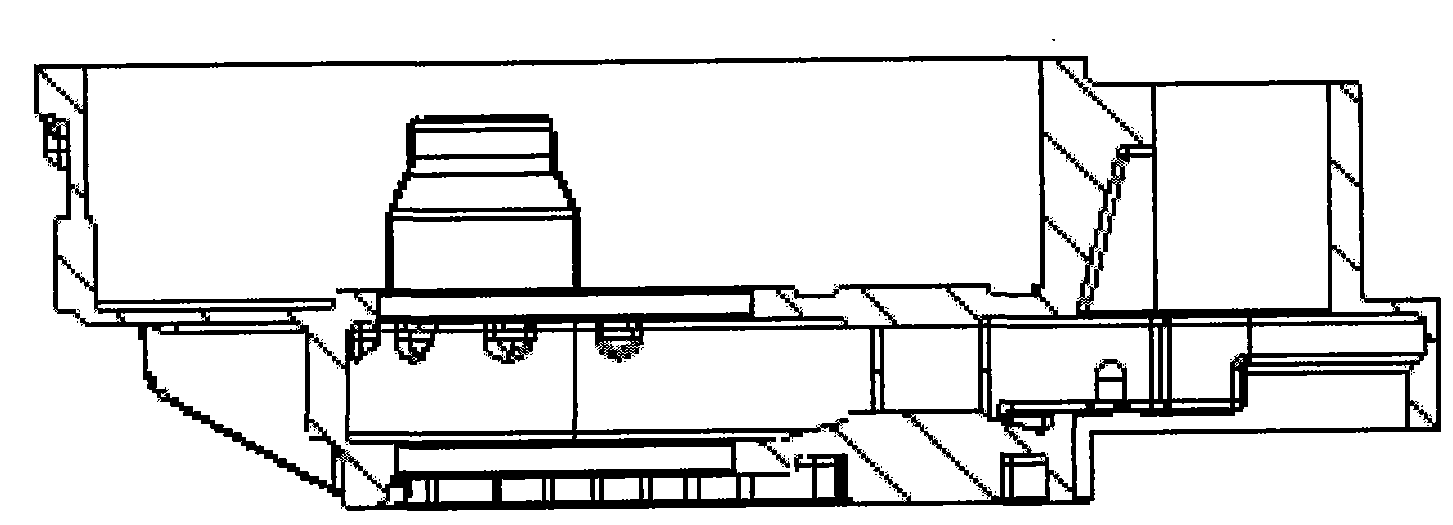

Lost foam casting process for flywheel cover of heavy truck engine

A technology of engine flywheel housing and lost foam casting, which is used in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of reduced sand mold accuracy, large machining workload, and surface quality degradation, and achieves reduced machining workload. , The effect of less machining parts and reduction of internal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A method for casting a heavy truck engine flywheel housing based on lost foam technology, which includes the following steps and processes:

[0032] ①. Design and manufacture large-pitch flexible drive lost foam production line, mainly including: large-pitch flexible drive automatic production line; dry sand processing system with rolling sand cooling bed as the core equipment; The modeling area composed of platform and humanized design herringbone sand storage bucket; self-discharging sand angle air chamber vacuum sand box, etc. The large-pitch flexible drive lost foam production line is designed and produced by Gu'an Jining Foundry Equipment Co., Ltd.

[0033] ②. Divide the flywheel housing into several splicing blocks. The number and direction of the splicing blocks after cutting should be comprehensively considered. The factors that are conducive to pouring and splicing. Then according to the structure of the splicing blocks, foam molding molds for each splicing bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Eccentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com