A Semi-hot Precision Die Forging Forming Process for Titanium Alloy Forgings

A technology of precision die forging and forming technology, which is applied in the direction of metal processing equipment, etc. It can solve the problems of reduced fatigue performance, poor thermal processing performance of titanium alloy, and flash shear residue, etc., to reduce the amount of machining work and improve fatigue performance. High, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

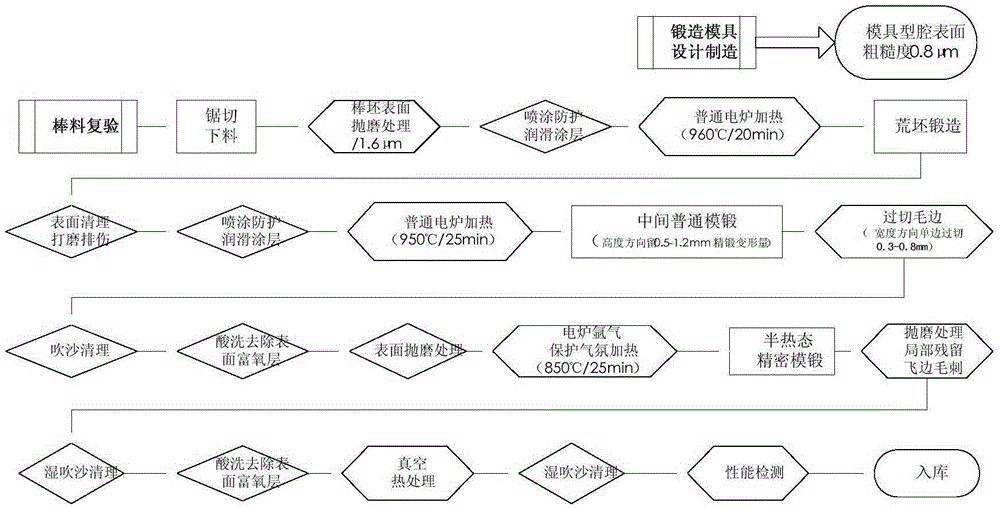

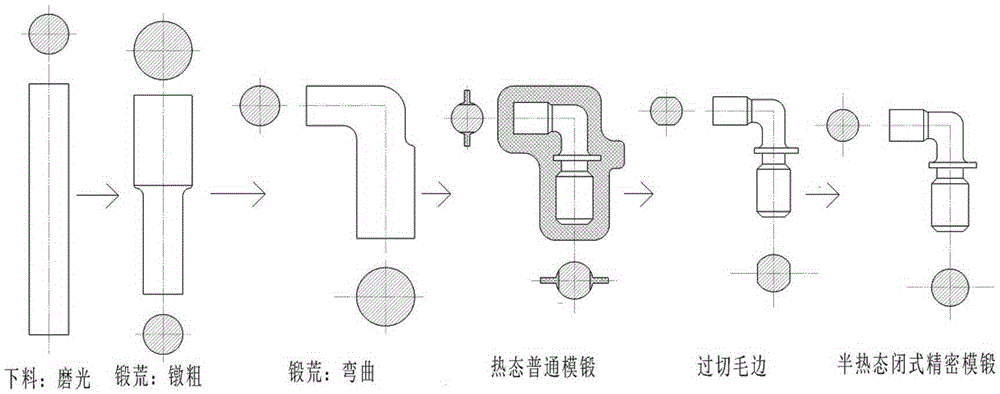

[0044] Preparation of high-precision surface die forgings for TC4 titanium alloy two-way elbow joints, forging and forming schematic diagrams are attached figure 2 .

[0045]1) Die processing: design and manufacture common forging dies for pre-forging (cavity roughness 1.6 μm) and high-precision surface precision forging dies for final forging (cavity roughness 0.8 μm).

[0046] 2) Billet preparation: Prepare TC4 titanium alloy rods with a diameter of φ20mm according to the specifications and weight calculated by the process.

[0047] 3) Spraying lubrication: After preheating the TC4 titanium alloy bar at 190°C for 6 hours, spray the glass lubricant for forging on the surface.

[0048] 4) Forging blanks: After heating TC4 titanium alloy rods at 950°C in an electric furnace, free forging equipment is used to forge titanium alloy rods into blanks whose shape and size are close to those of die forgings. Wherein, the difference between the size of the forged titanium alloy bar ...

Embodiment 2

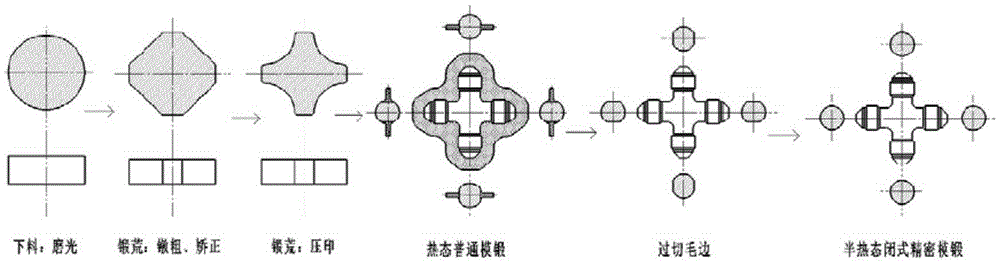

[0059] Preparation of high-precision surface die forgings for TC6 titanium alloy four-way pipe joints, forging and forming schematic diagrams are attached image 3 .

[0060] 1) Die processing: design and manufacture common forging dies for pre-forging (cavity roughness 1.6 μm) and high-precision surface precision forging dies for final forging (cavity roughness 0.8 μm).

[0061] 2) Billet preparation: prepare TC6 titanium alloy rods with a diameter of φ80mm according to the specifications and weight calculated by the process.

[0062] 3) Spraying lubrication: After preheating the titanium alloy bar at 210°C for 1 hour, the surface is sprayed with glass lubricant for forging.

[0063] 4) Forging blank: After the TC6 titanium alloy bar is heated in an electric furnace at 940°C, the titanium alloy bar is forged into a blank whose shape and size are close to die forgings by using free forging equipment. Wherein, the difference between the forged size of the forged titanium allo...

Embodiment 3

[0074] 1) Die processing: design and manufacture common forging dies with a cavity roughness of 1.6 μm for pre-forging and precision forging dies with a cavity roughness of 0.8 μm for final forging;

[0075] 2) Spraying lubrication: design the specifications and dimensions of the final die forging, and calculate the required TC4 titanium alloy bar according to the final specifications and dimensions, and spray the glass lubricant for forging on the surface of the preheated titanium alloy bar; among them, The preheating temperature is 190°C and the time is 6h.

[0076] 3) Forging blank: After heating the sprayed titanium alloy bar in an electric furnace at a temperature lower than the phase transition point of the titanium alloy bar at 30°C to 50°C, the free forging equipment is used to forge the titanium alloy bar into titanium The size of alloy blanks and titanium alloy blanks matches that of die forgings; the difference between the size of titanium alloy blanks and that of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com