Quantitative test method for endogenous excitation load of equipment under joint action of unbalanced turbulence force and unbalanced turbulence moment

A combined action, in-equipment technology, used in machine/structural component testing, vibration testing, measuring devices, etc., can solve the problem of not proposing equipment estimation methods, not considering whether the base has an impact on the intrinsic characteristics of the equipment, and uncertainties. Problems such as methods of equivalent mass and equivalent disturbing force of equipment vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

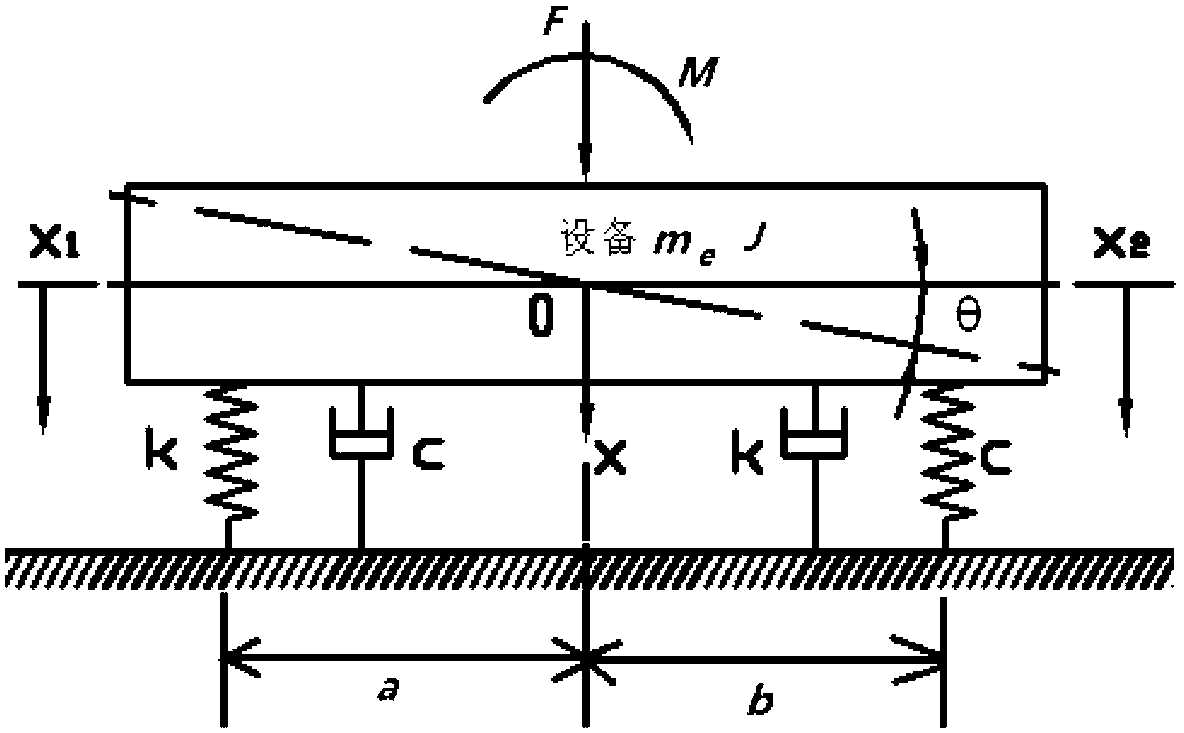

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0023] Combined with Figures 1 to 3, it is divided into the following steps:

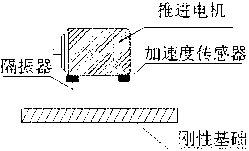

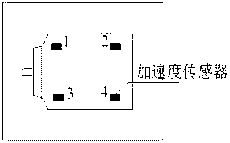

[0024] 1. Layout of the test bench

[0025] Install the equipment on a rigid stand with great mass and rigidity to ensure no vibration velocity on the surface of the rigid stand. Select a group of vibration isolators of the same type, arrange them on the machine feet of the equipment to make the equipment run smoothly, and fix the vibration isolators on the rigid platform with bolts. Because this patent is mainly aimed at the endogenous characteristics of rotating equipment (that is, equipment with exciting torque), such as propulsion motors, diesel generator sets, various seawater pumps, etc., in order to obtain the endogenous characteristics of these equipment, the equipment must be stabilized The ground is fixed on the vibration isolator so that the equipment can run smoothly and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com