Patents

Literature

35results about How to "Quantitative evaluation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Detection method and detection device of grouting reinforcement effect in tunnel

InactiveCN101846604AQuick evaluationQuantitative evaluationMaterial strength using tensile/compressive forcesSoil massClassical mechanics

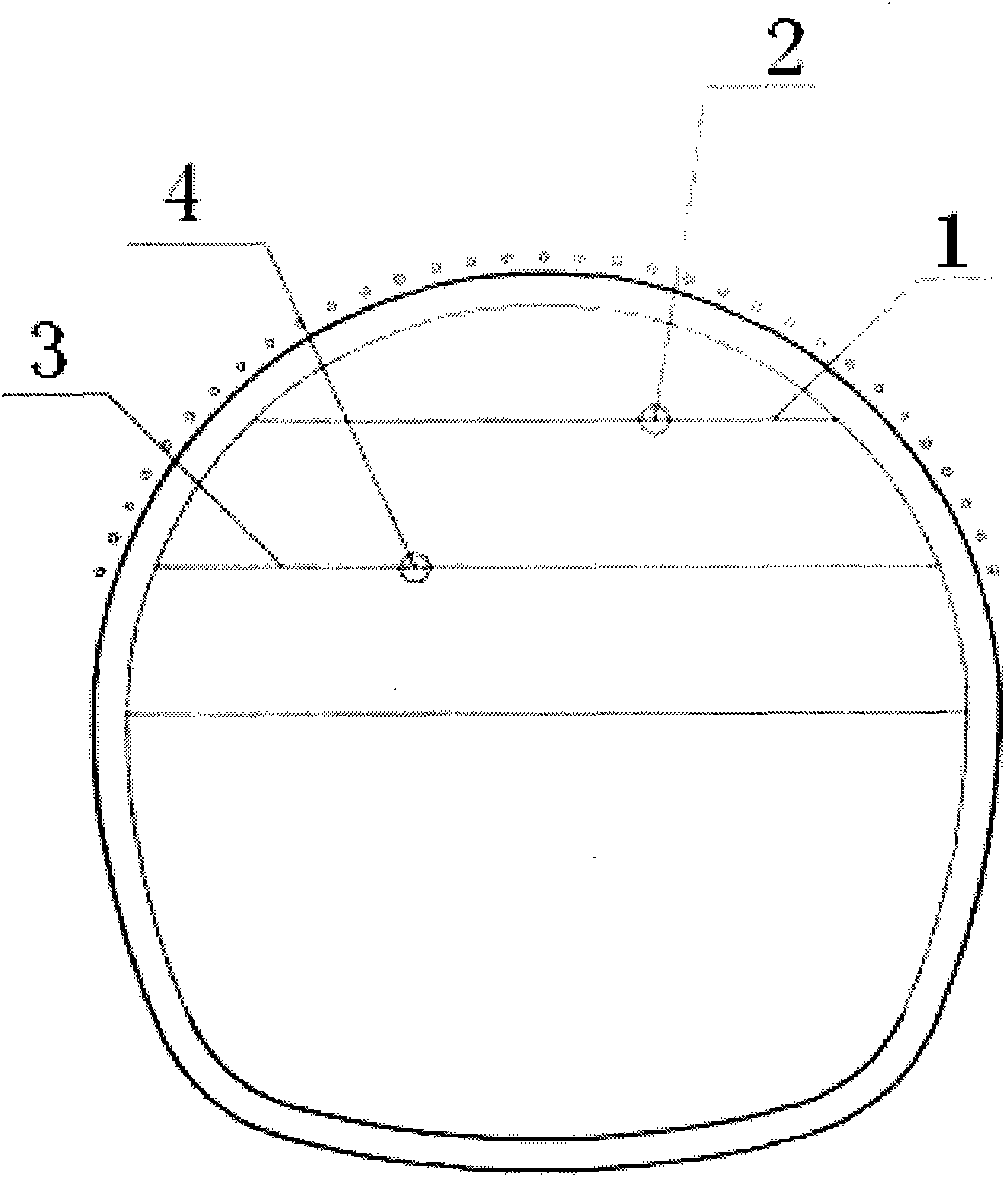

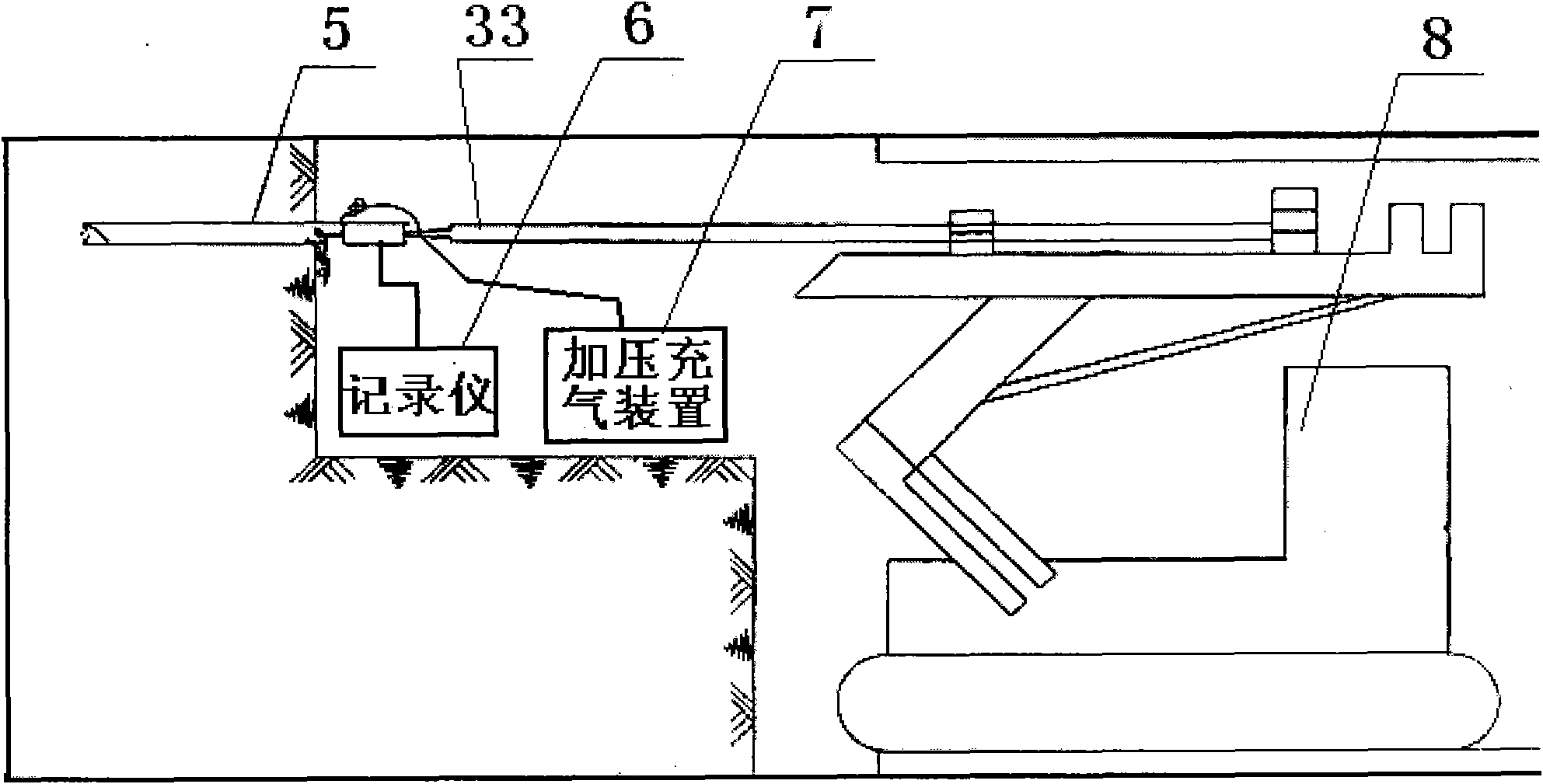

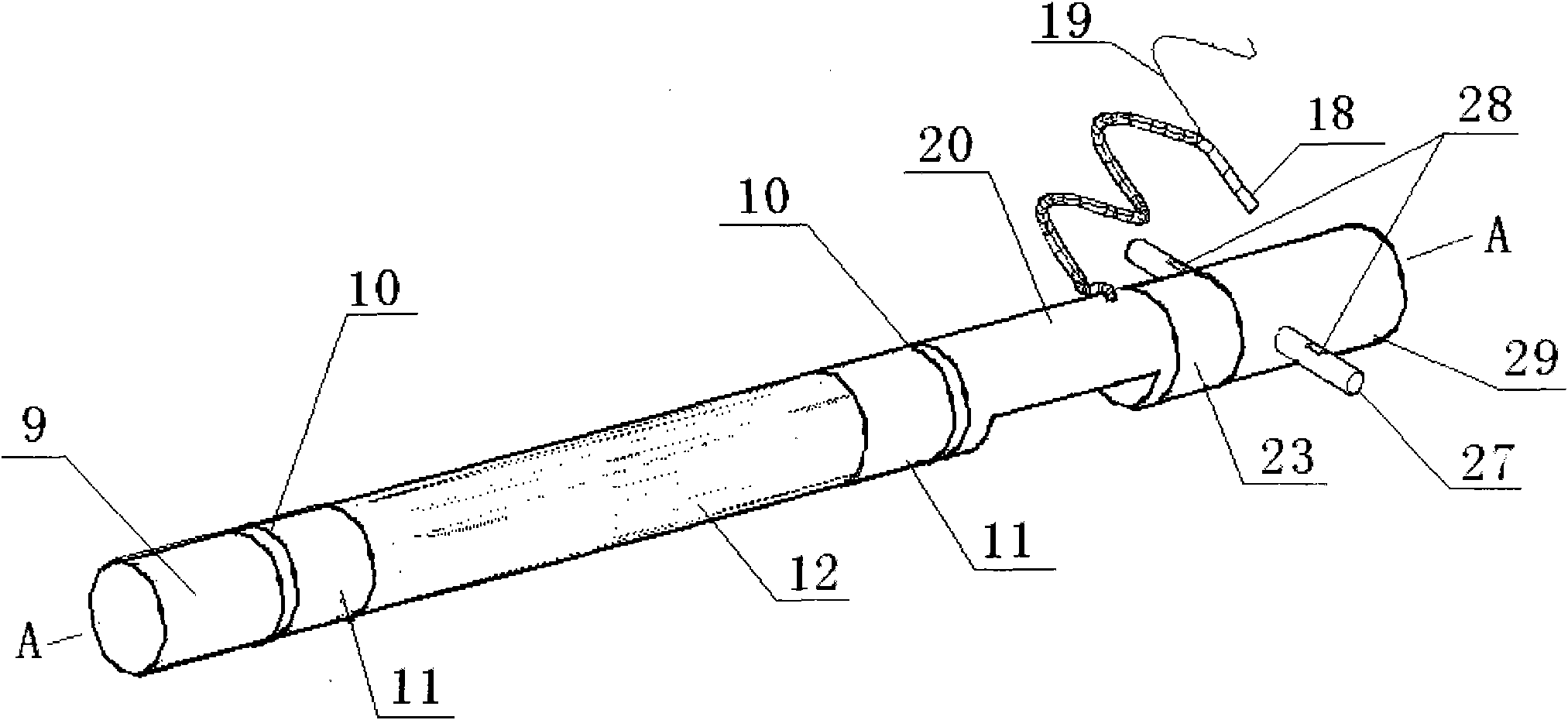

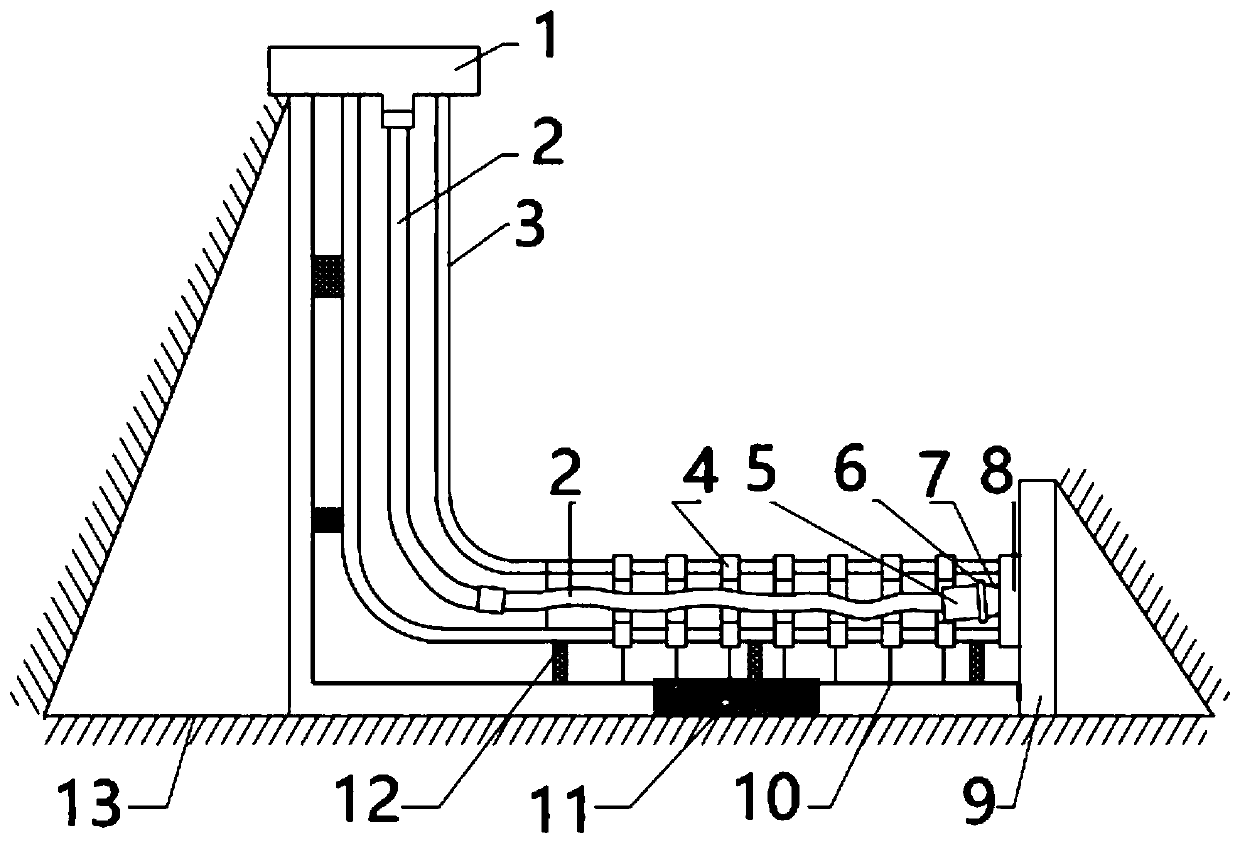

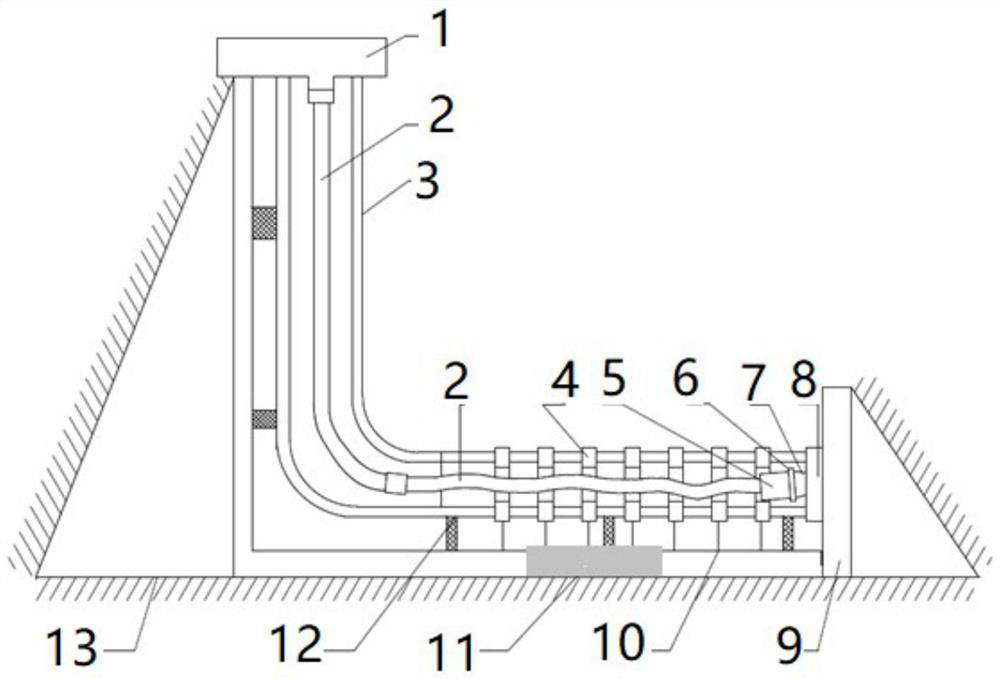

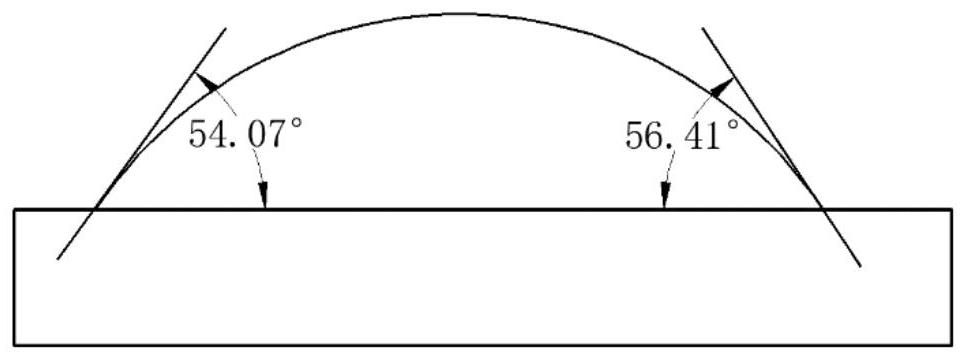

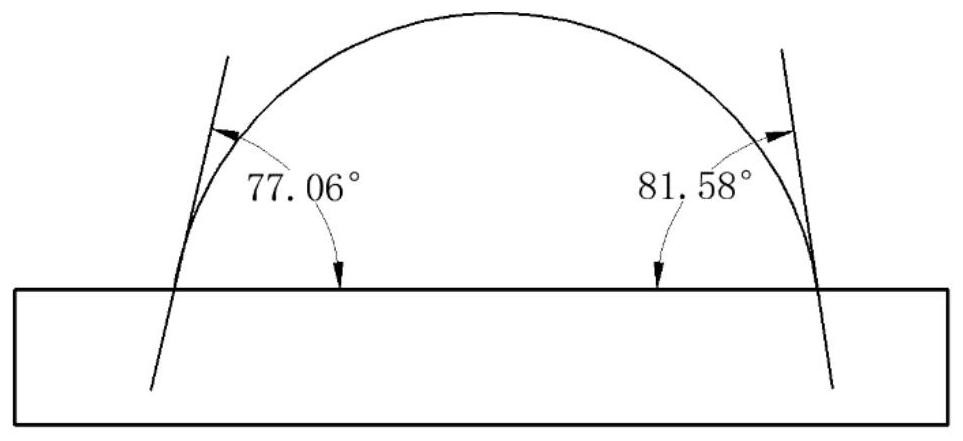

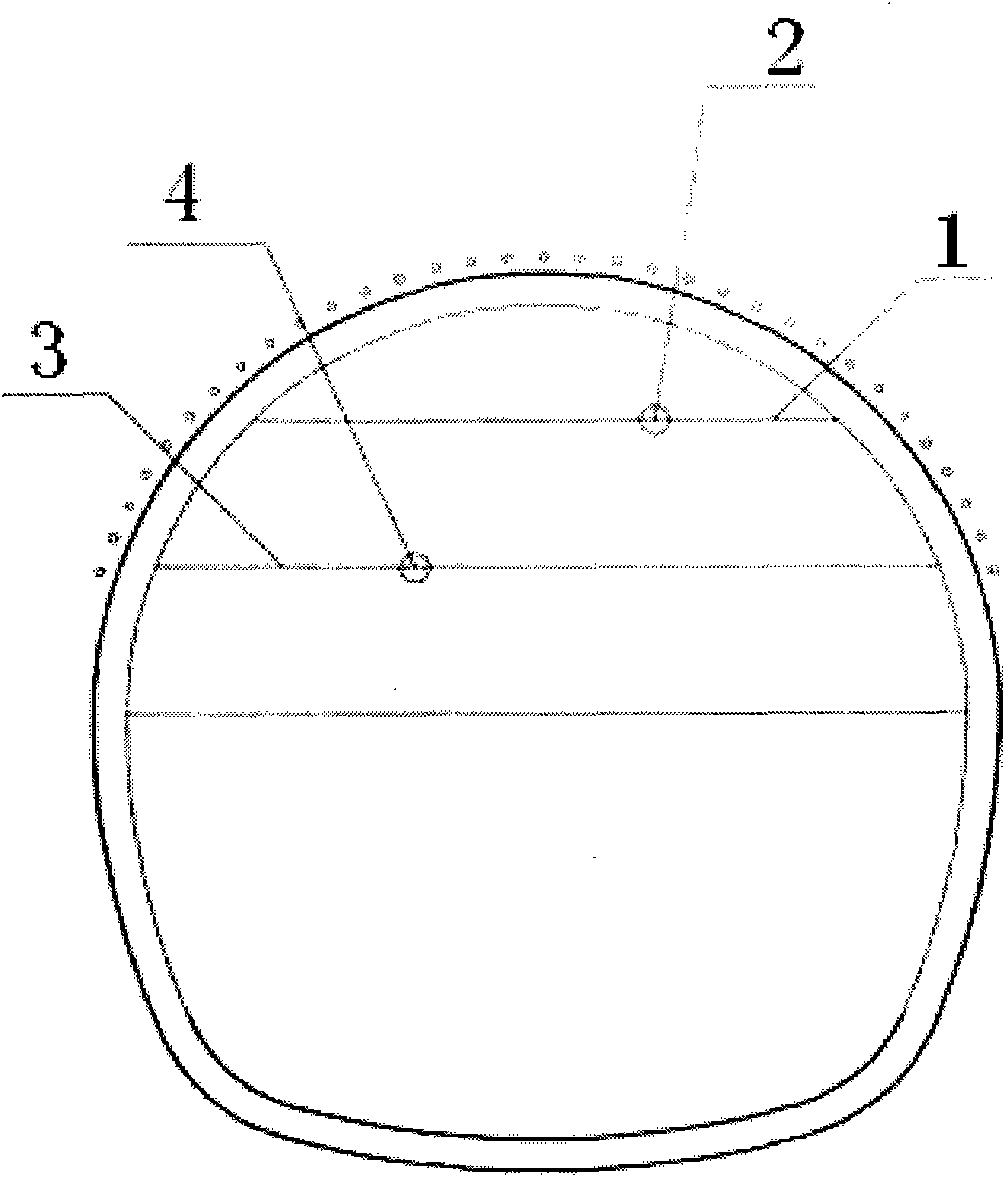

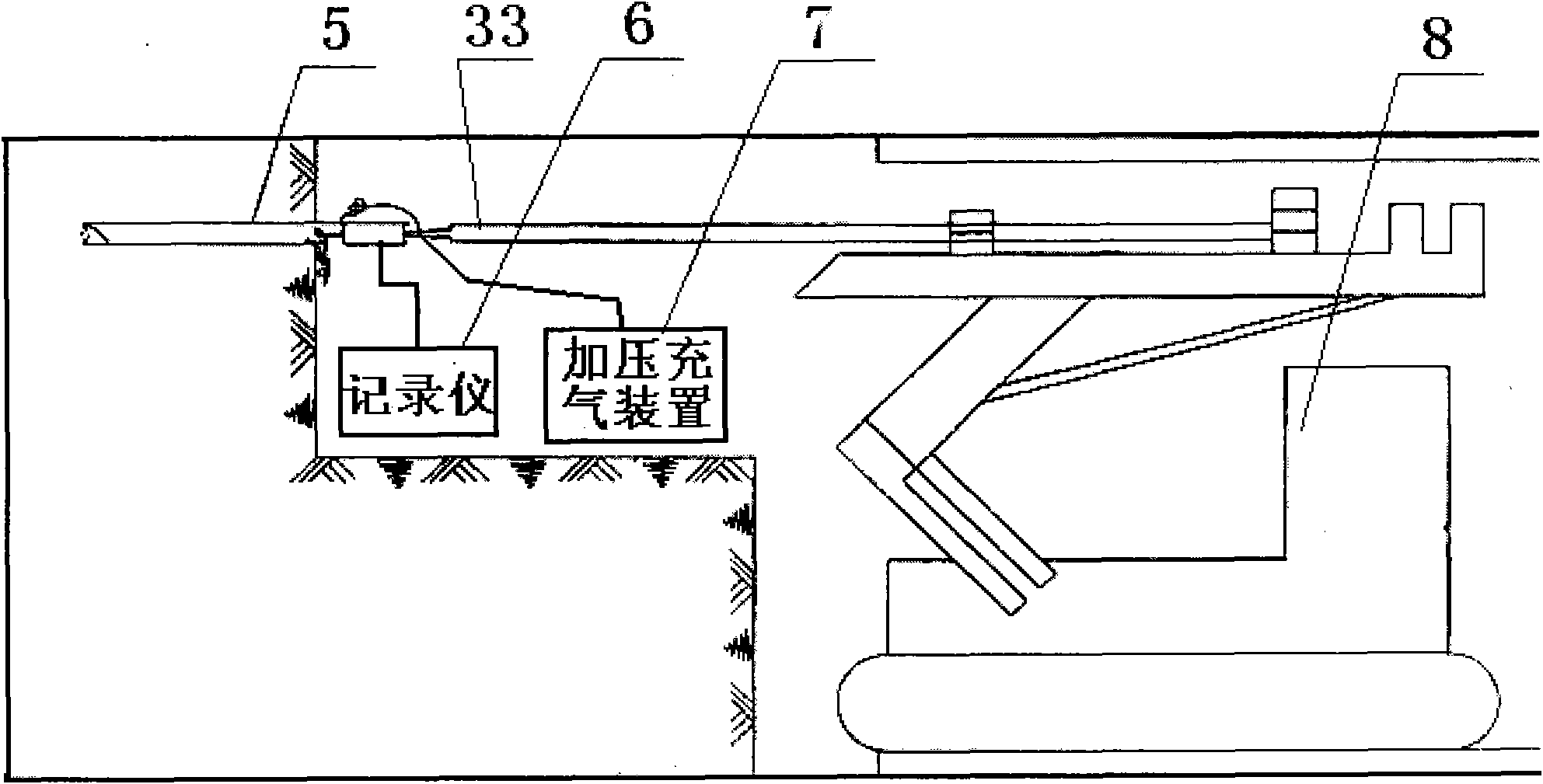

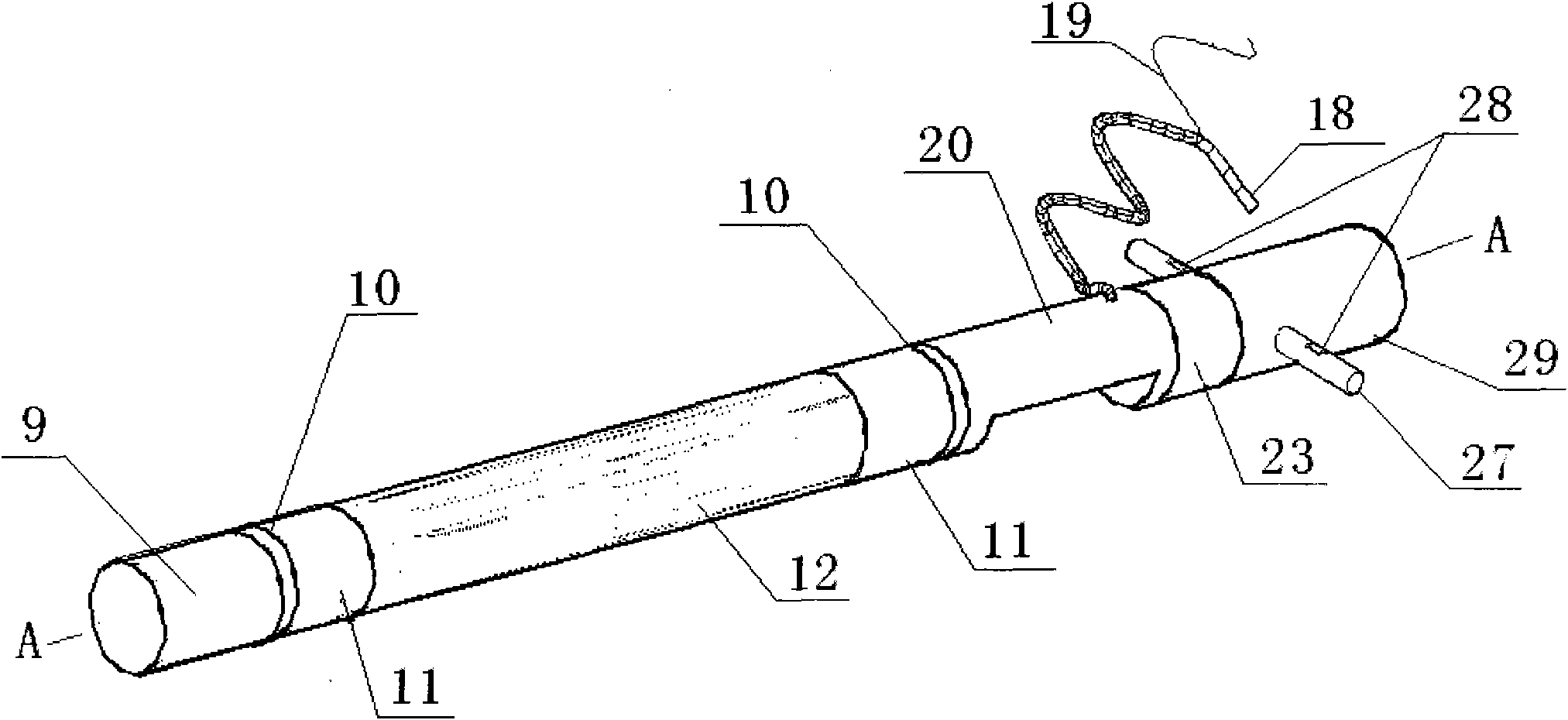

The invention relates to a detection method and a detection device of grouting reinforcement effect in a tunnel, belonging to the field of tunnel engineering. The detection method of grouting reinforcement effect in the tunnel comprises the following steps: horizontally and respectively drilling the detection device into tunnel headings before and after grouting by using a drilling machine; forming an elliptical pilot tunnel in soil mass; inflating and pressurizing the measuring gas chamber of the device, and detecting the displacement of the short axis and the long axis of the elliptical pilot tunnel under the pressure at all levels; computing mechanical parameters (coefficient KO of earth pressure at rest, Poisson ratio mu and elastic modulus E) of the soil mass before and after grouting according to the elasticity theory formula; comparing the mechanical parameters of the soil mass before and after grouting; and making a conclusion of the grouting reinforcement effect according to the variation of the mechanical parameters of the soil mass before and after grouting. The core component of the detection device is the measuring gas chamber which is composed of a tubular expanded inner cavity and a rubber expanded film, and after the device is drilled into the soil mass, the displacement sensor and the pressure sensor of the measuring gas chamber are used for detecting field data. The invention has simple operation and can quickly, quantitatively and scientifically evaluate the grouting reinforcement effect.

Owner:BEIJING JIAOTONG UNIV

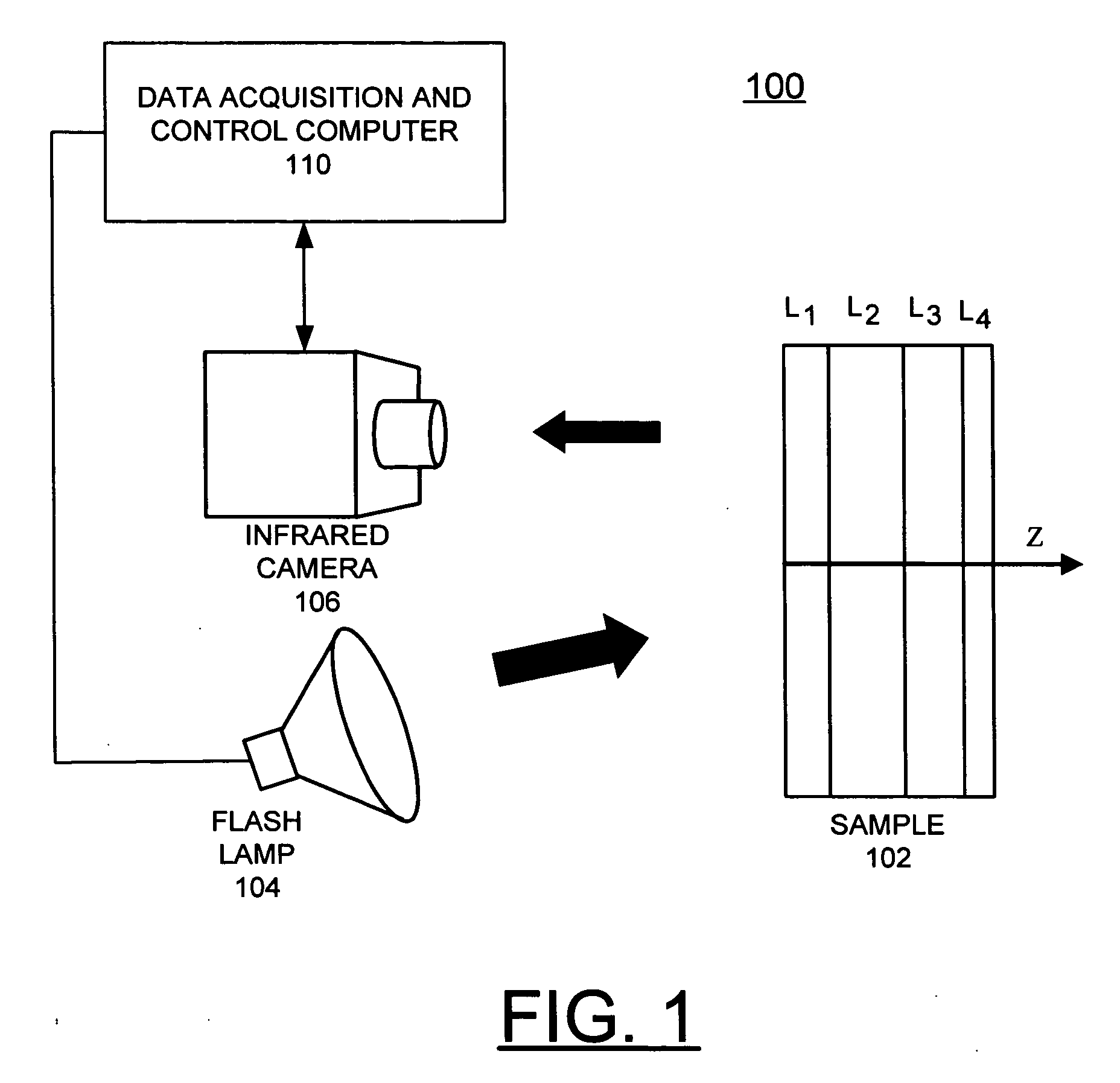

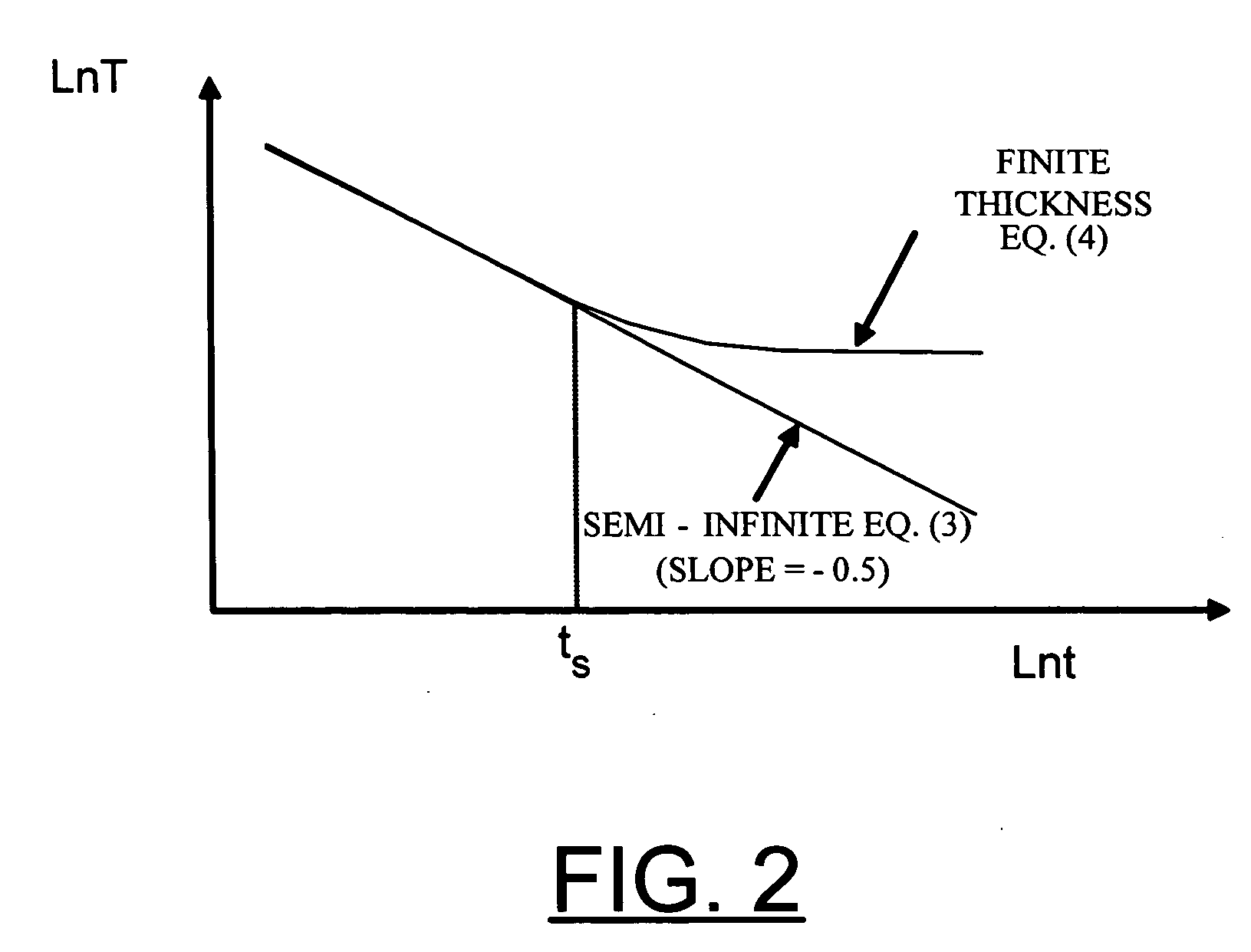

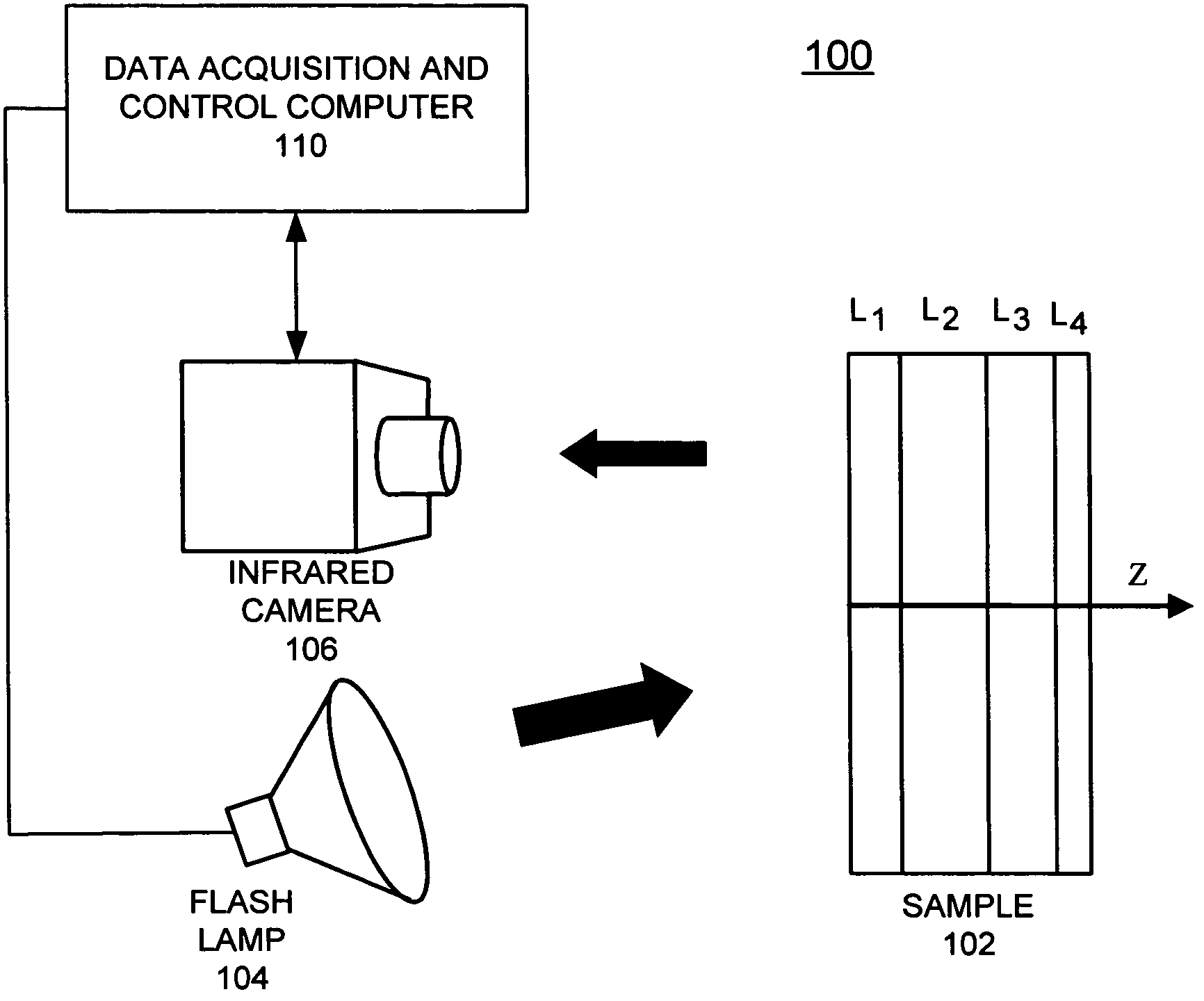

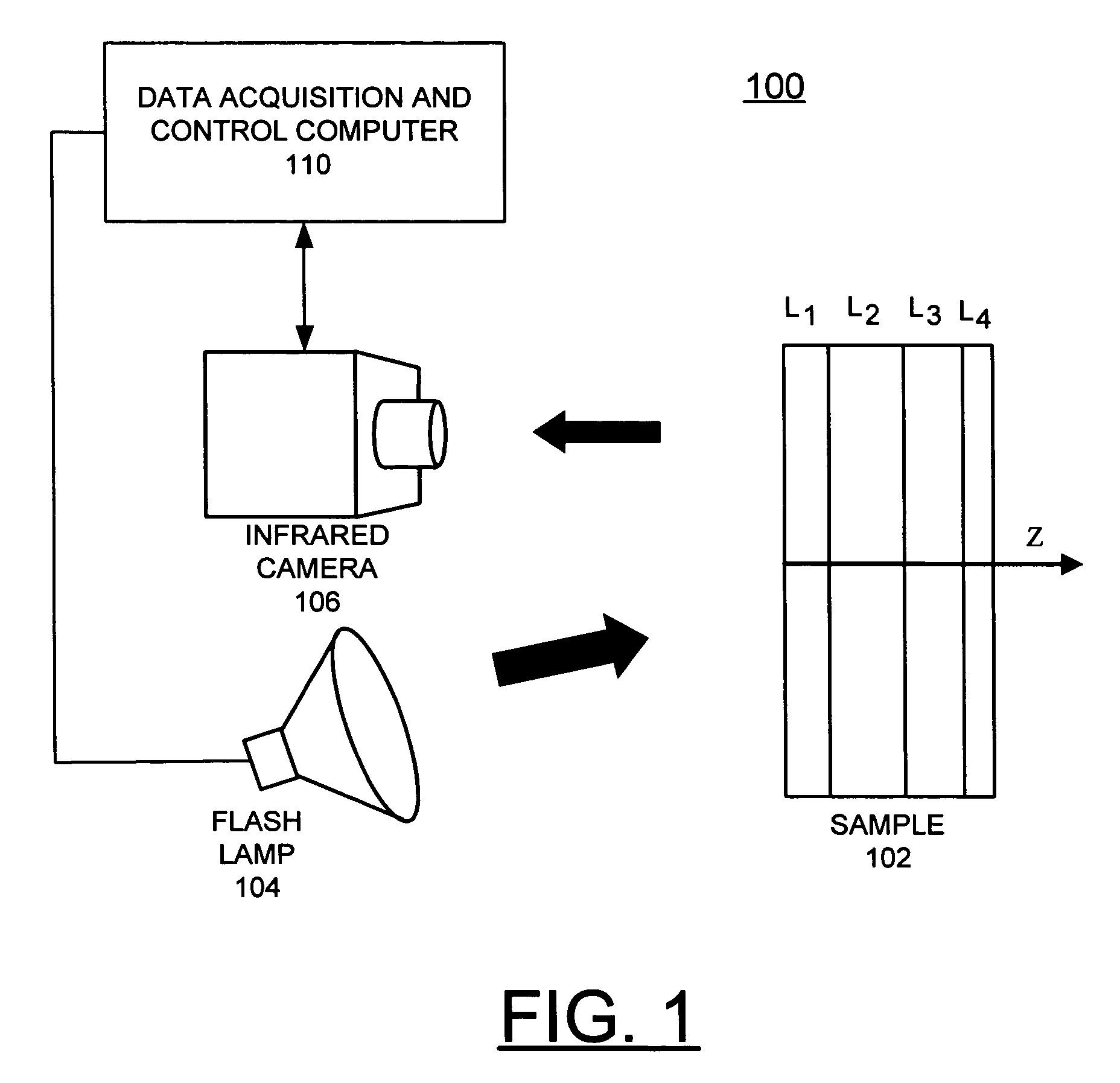

Method for analyzing multi-layer materials from one-sided pulsed thermal imaging

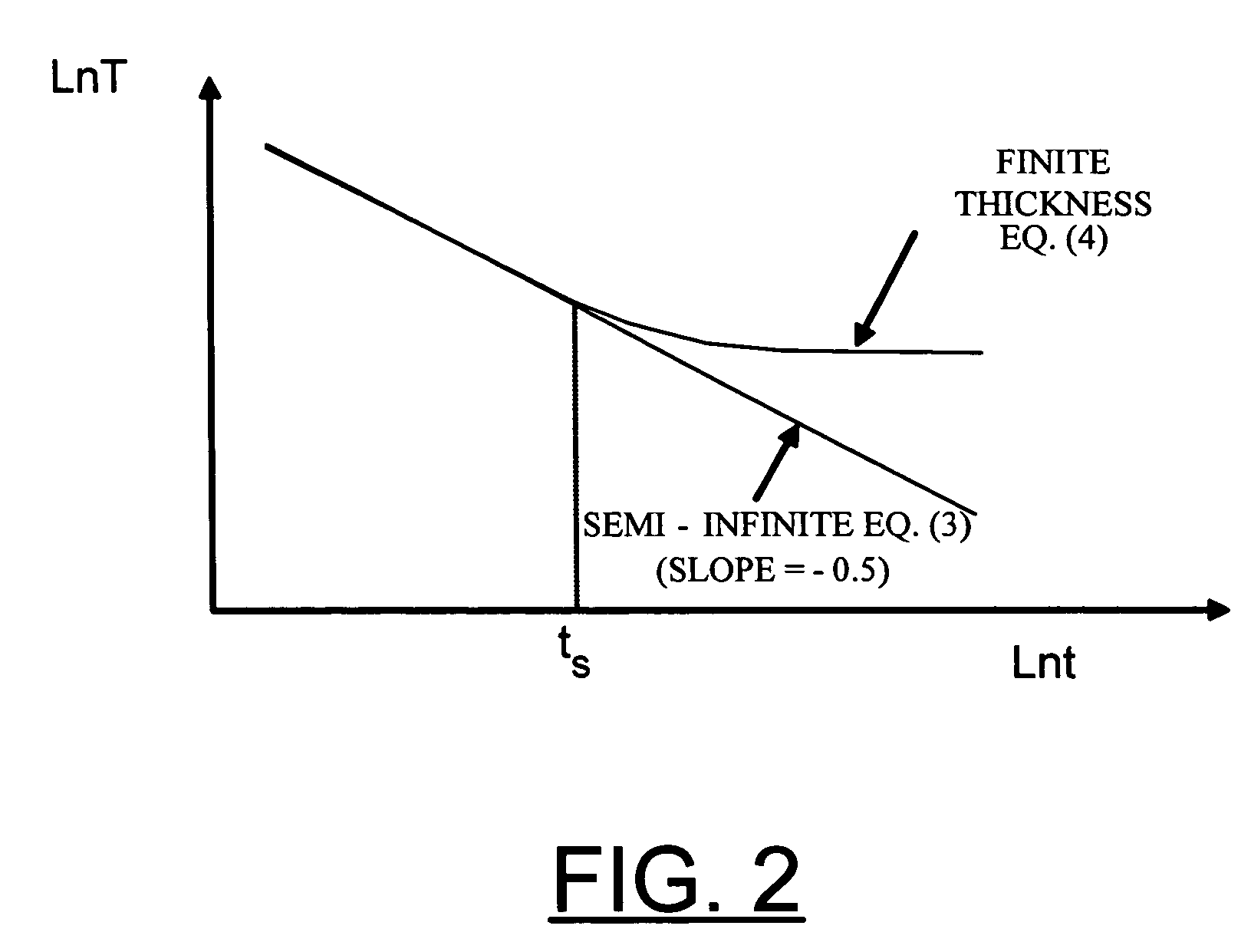

InactiveUS20070299628A1Quantitative evaluationFast and 00 % area inspectionDigital computer detailsMeasurement arrangements for variablePorosityImaging data

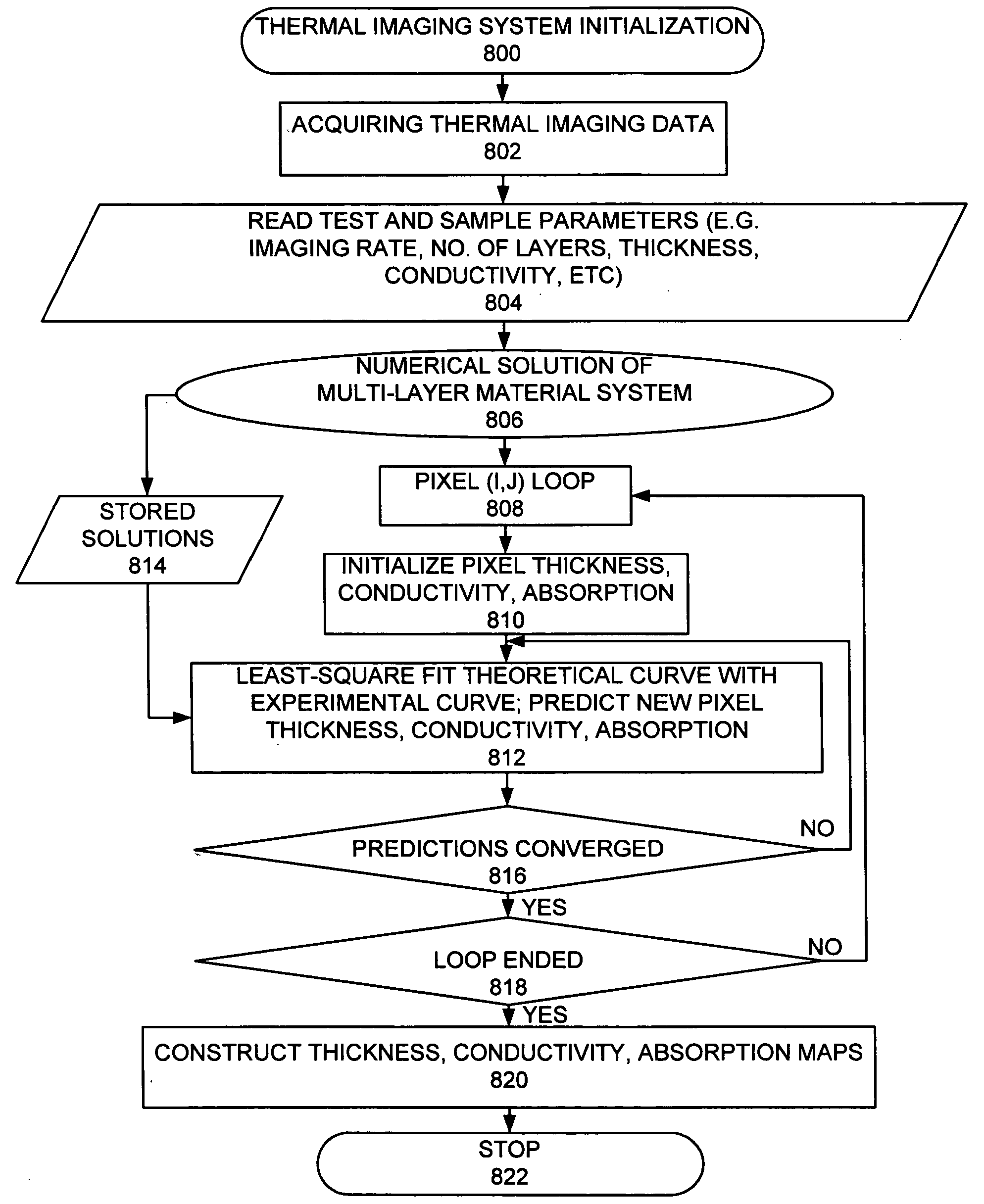

A method, apparatus, and computer program product provides automated analysis of thermal imaging data for multi-layer materials based upon a theoretical model of a multi-layer material system, which is solved numerically. The computer-implemented method effectively processes the volume heating effect for thermal barrier coatings (TBCs), since quantitative evaluation of TBC thickness and conductivity is particularly important. TBC thickness is a processing parameter and required to be monitored. TBC conductivity is a measure of TBC quality because it is directly related with TBC density / porosity, microcracking and interface cracks. Because this method is an imaging technology, it can be used for fast and 100% area inspection of larger TBC surfaces, such as combustor liners.

Owner:UCHICAGO ARGONNE LLC

Method for analyzing multi-layer materials from one-sided pulsed thermal imaging

InactiveUS7769201B2Quantitative evaluationFast and 00 % area inspectionCharacter and pattern recognitionScanning probe microscopyPulse thermographyPorosity

A method, apparatus, and computer program product provides automated analysis of thermal imaging data for multi-layer materials based upon a theoretical model of a multi-layer material system, which is solved numerically. The computer-implemented method effectively processes the volume heating effect for thermal barrier coatings (TBCs), since quantitative evaluation of TBC thickness and conductivity is particularly important. TBC thickness is a processing parameter and required to be monitored. TBC conductivity is a measure of TBC quality because it is directly related with TBC density / porosity, microcracking and interface cracks. Because this method is an imaging technology, it can be used for fast and 100% area inspection of larger TBC surfaces, such as combustor liners.

Owner:UCHICAGO ARGONNE LLC

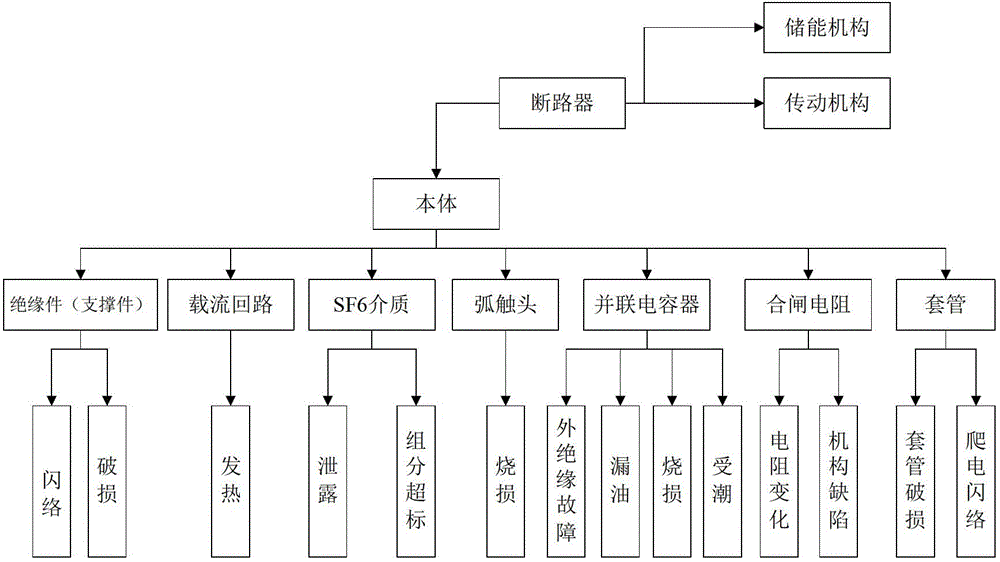

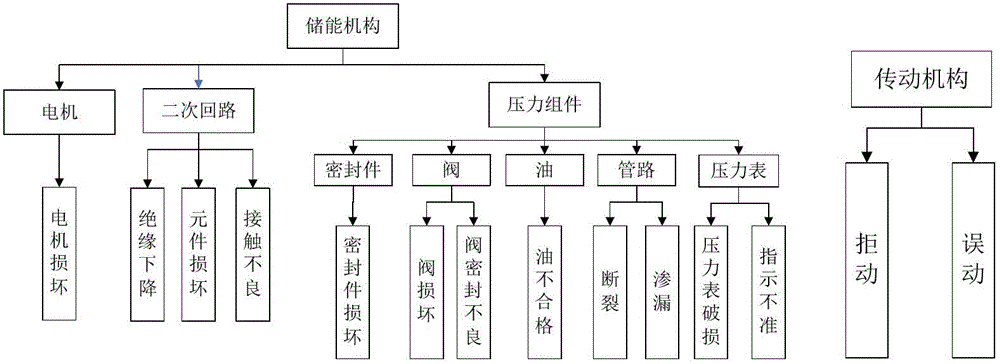

Short-term reliability evaluation method of high-voltage breaker

InactiveCN103336879AAccurate assessmentEvaluation QuantificationSpecial data processing applicationsEquipment DefectsShort terms

The invention relates to a short-term reliability evaluation method of a high-voltage breaker. The current and recent reliability of the high-voltage breaker is evaluated accurately and quantitatively by a fault tree and fault mode evaluation model via data acquired by all detection means of the current breaker, including routine patrol, special patrol, preventive test data, diagnostic test data, basic standing book information of equipment, equipment defects over the years, fault records and the like. The method for evaluating the reliability of the high-voltage breaker has the advantages of conciseness, intelligibility, accuracy, visuality, quantification and the like.

Owner:YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST +1

Method for representing center segregation of high-carbon steel wire rod

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

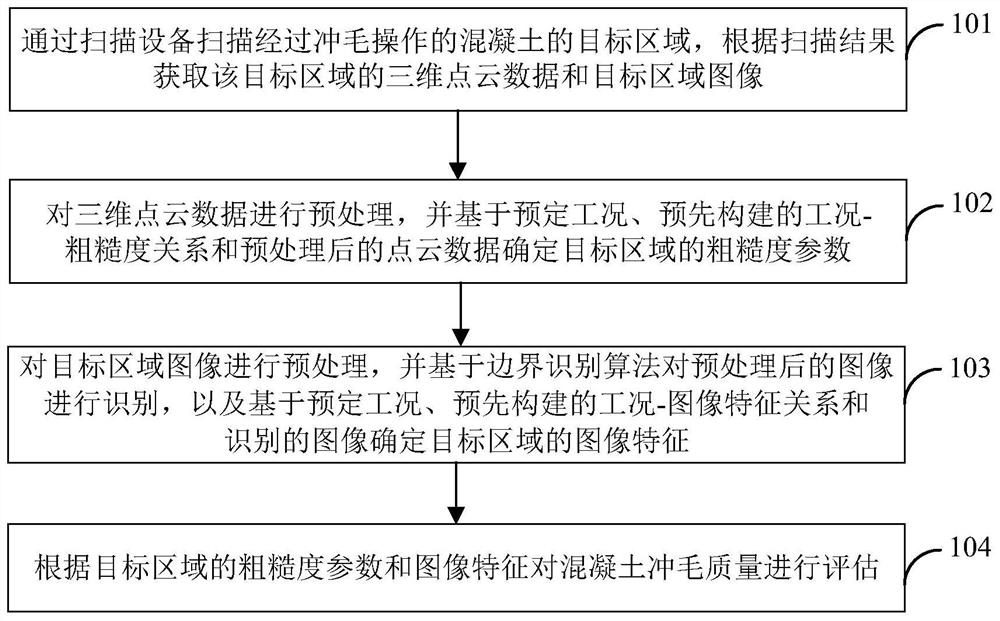

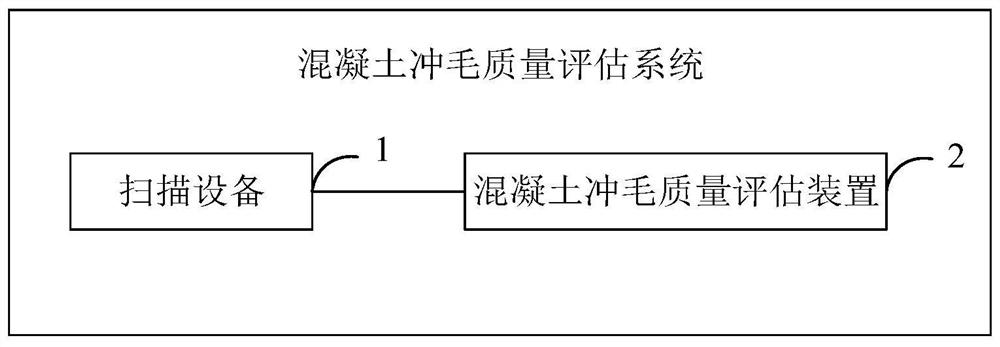

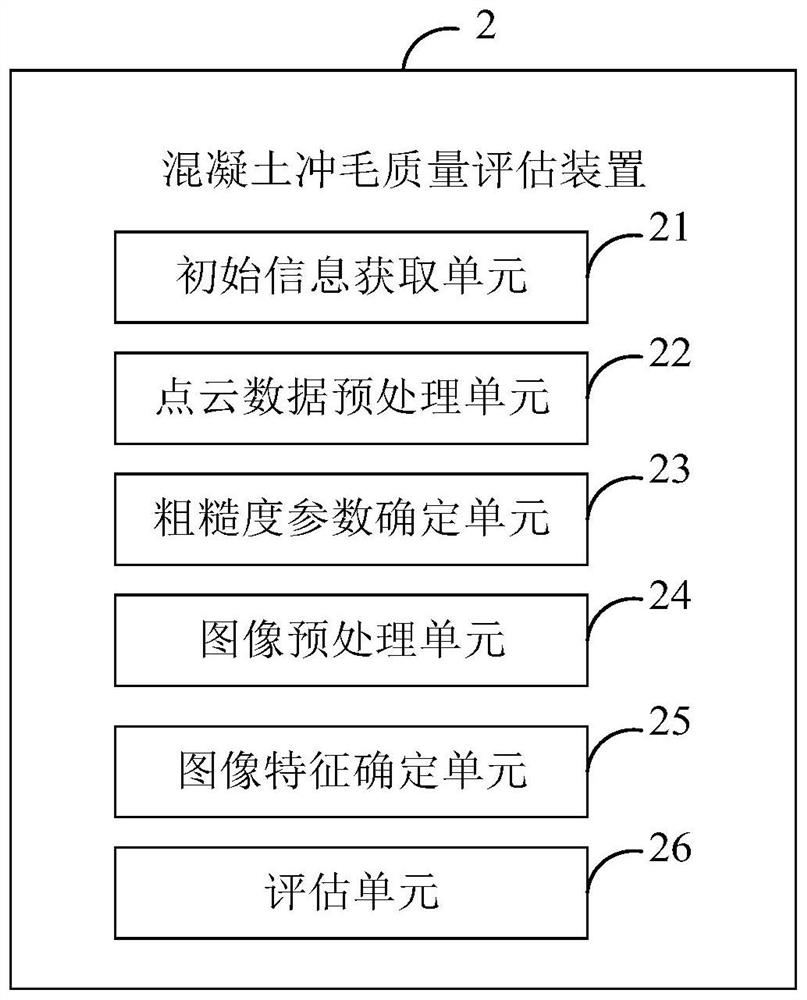

Concrete wool flushing quality evaluation method, device and system

PendingCN112819781AEffective evaluationAccurate evaluationImage enhancementImage analysisPoint cloudRecognition algorithm

The invention discloses a concrete wool washing quality evaluation method, device and system, and the method comprises: scanning a target region of concrete subjected to wool washing operation through scanning equipment, and obtaining the three-dimensional point cloud data of the target region and a target region image according to a scanning result; preprocessing the three-dimensional point cloud data, and determining roughness parameters of the target area based on a predetermined working condition, a pre-constructed working condition-roughness relationship and the preprocessed point cloud data, wherein the roughness parameters includes at least one of the following: a filling volume, an average fluctuation degree, a normal vector statistical index, a surface area expansion rate and a curvature statistical index; preprocessing the target area image, identifying the preprocessed image based on a boundary identification algorithm, and determining image features of the target area based on a predetermined working condition, a pre-constructed working condition-image feature relationship and the identified image; and evaluating the concrete scouring quality according to the roughness parameter and the image feature of the target area.

Owner:CHINA THREE GORGES PROJECTS DEV CO LTD +1

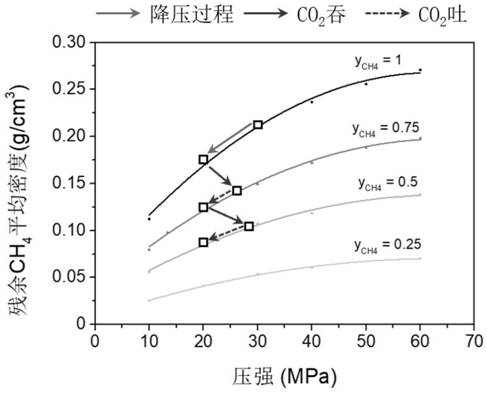

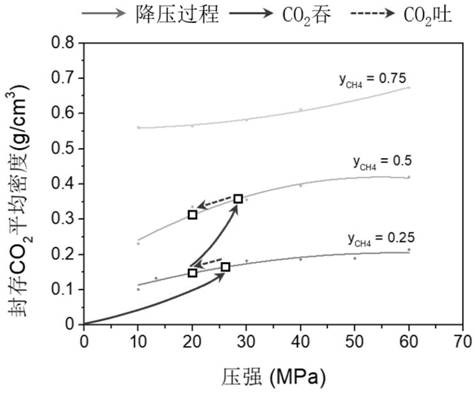

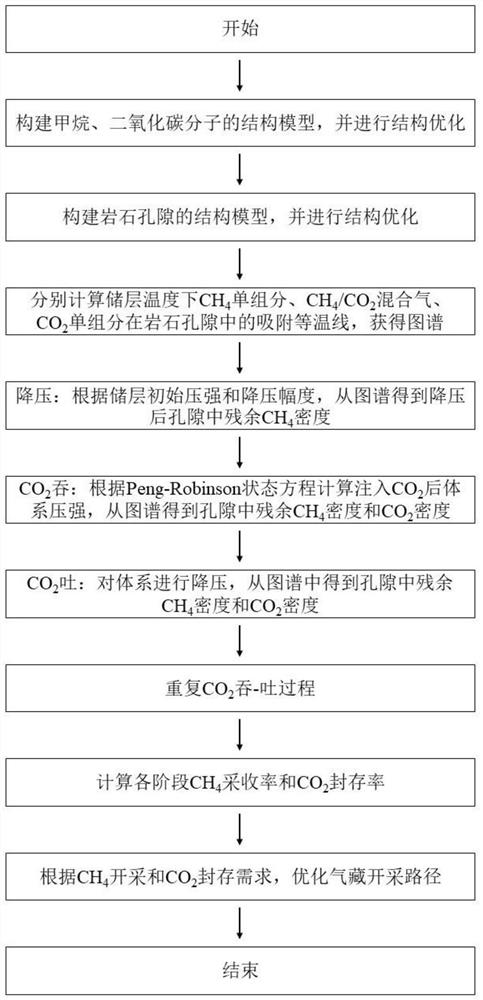

Method for quantitatively predicting exploitation and storage of carbon dioxide enhanced gas reservoir

ActiveCN113821937AOptimizing Mining PathsQuantitative evaluationDesign optimisation/simulationSpecial data processing applicationsSoil sciencePhysical chemistry

The invention provides a method for quantitatively predicting exploitation and storage of a carbon dioxide enhanced gas reservoir, which realizes simulation reduction of multiple continuous injection-production processes in a mode of combining GCMC and PR-EOS, and comprises a primary pressure reduction process and multiple CO2 swallowing-spitting processes. Adsorption simulation of gas molecules in rock pores at different temperatures and pressures is realized by adopting a GCMC algorithm, an adsorption isotherm map of methane / carbon dioxide in the rock pores at a reservoir temperature is obtained, and the map is taken as a reference of gas density change in the rock pores in an injection-production process; and the pressure intensity of the system after CO2 injection is calculated through PR-EOS, and continuous injection and production are achieved. The yield increasing effect of CO2 can be quantitatively evaluated, the optimal exploitation path is obtained by comparing the methane recovery efficiency and the carbon dioxide storage rate under different injection paths, and the invention has guiding significance on engineering design of CO2 enhanced gas reservoir exploitation.

Owner:HUANENG CLEAN ENERGY RES INST +1

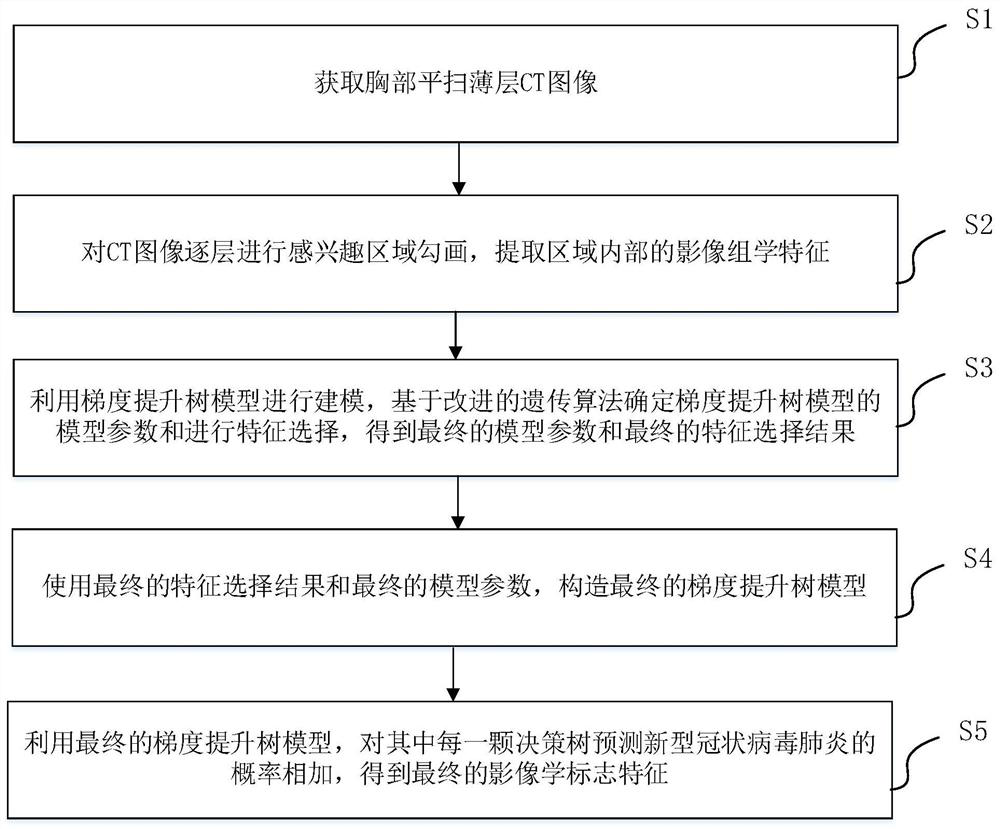

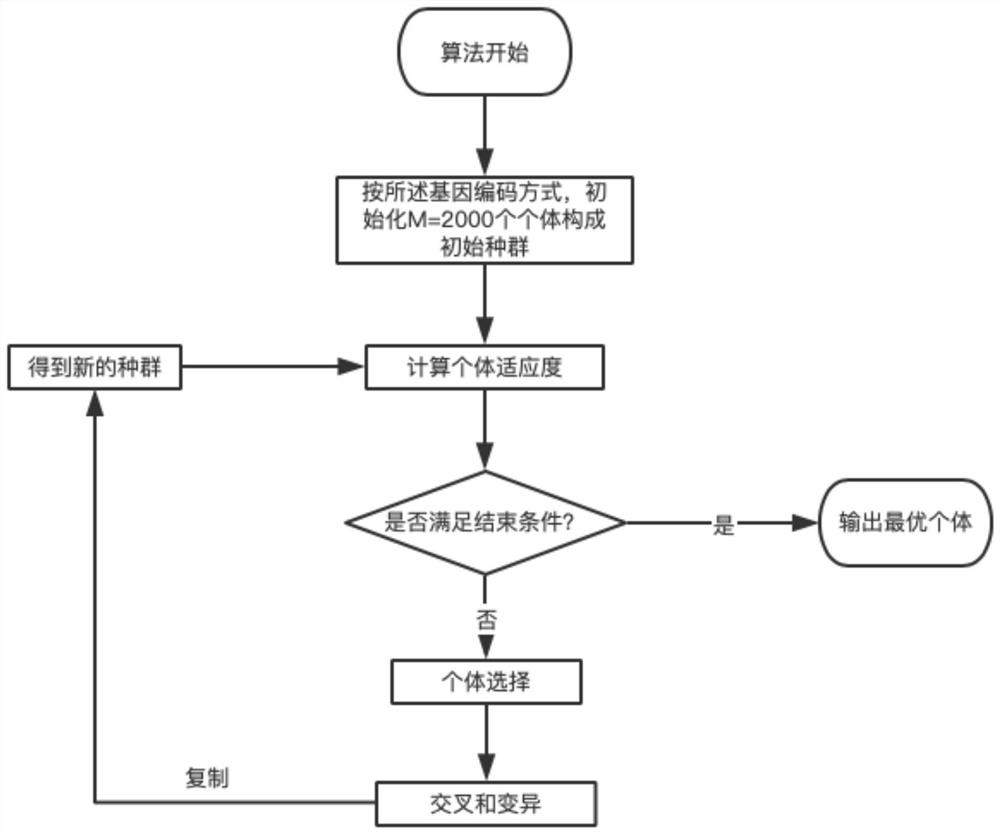

Imaging omics feature processing method and device for flat scanning CT image

PendingCN112233070AObjective assessmentQuantitative evaluationImage enhancementImage analysisGenetics algorithmsImaging study

The invention provides an imaging omics feature processing method and device for a flat scanning CT image. The method comprises the steps: obtaining a chest flat-scanning thin-layer CT image which comprises a CT image of novel coronavirus pneumonia and CT images of other viral pneumonia in the same period; carrying out region-of-interest sketching on the CT image layer by layer, and extracting animage omics feature in the region; modeling by using the gradient boosting tree model, determining model parameters of the gradient boosting tree model based on an improved genetic algorithm, and performing feature selection to obtain final model parameters and a final feature selection result, wherein the model parameters comprise the maximum weak learner number, the learning rate and the sub-sampling proportion; constructing a final gradient boosting tree model by using the final feature selection result and the final model parameters; adding the probability of predicting the novel coronavirus pneumonia of each decision tree by using the final gradient boosting tree model to obtain a final iconography marker feature.

Owner:HANGZHOU SHENRUI BOLIAN TECH CO LTD +1

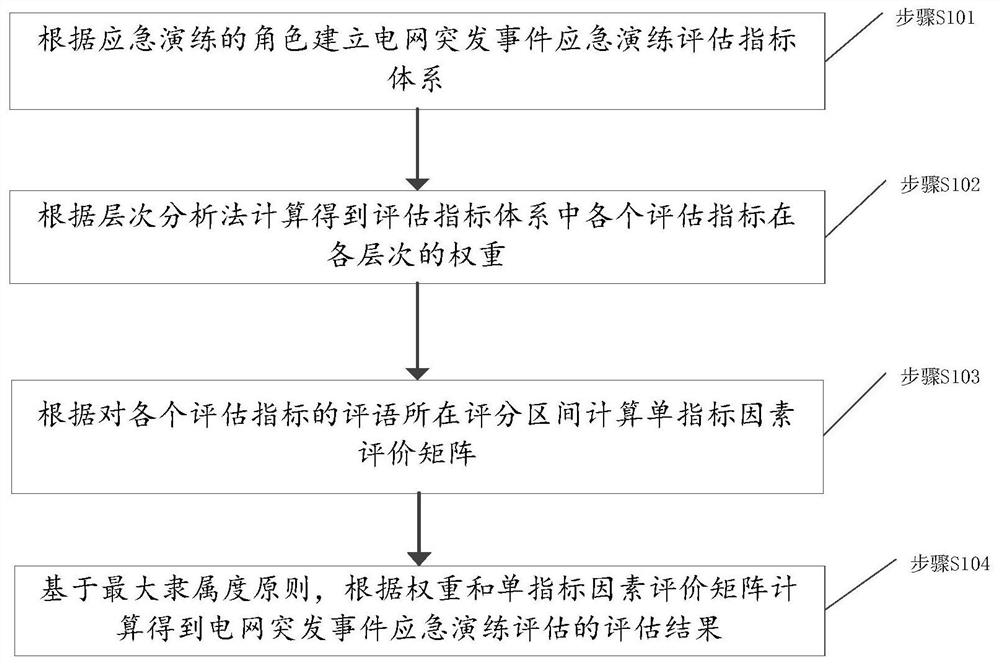

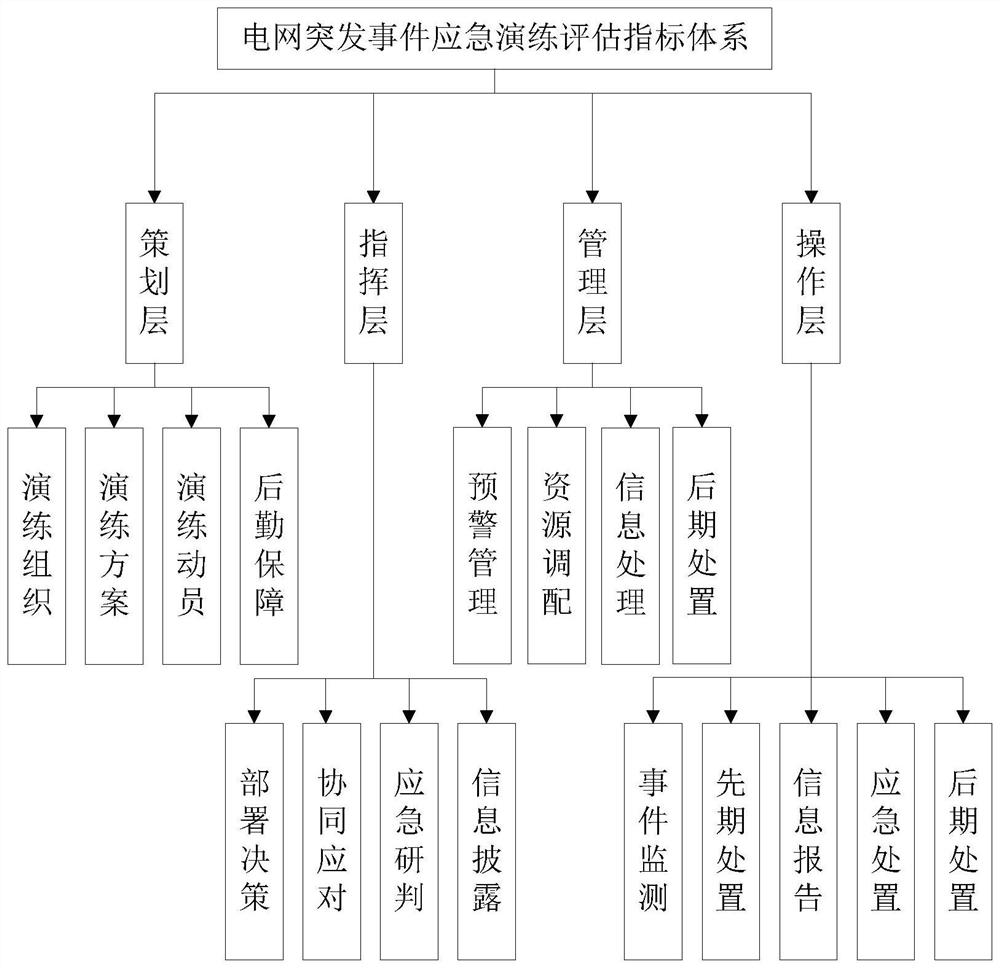

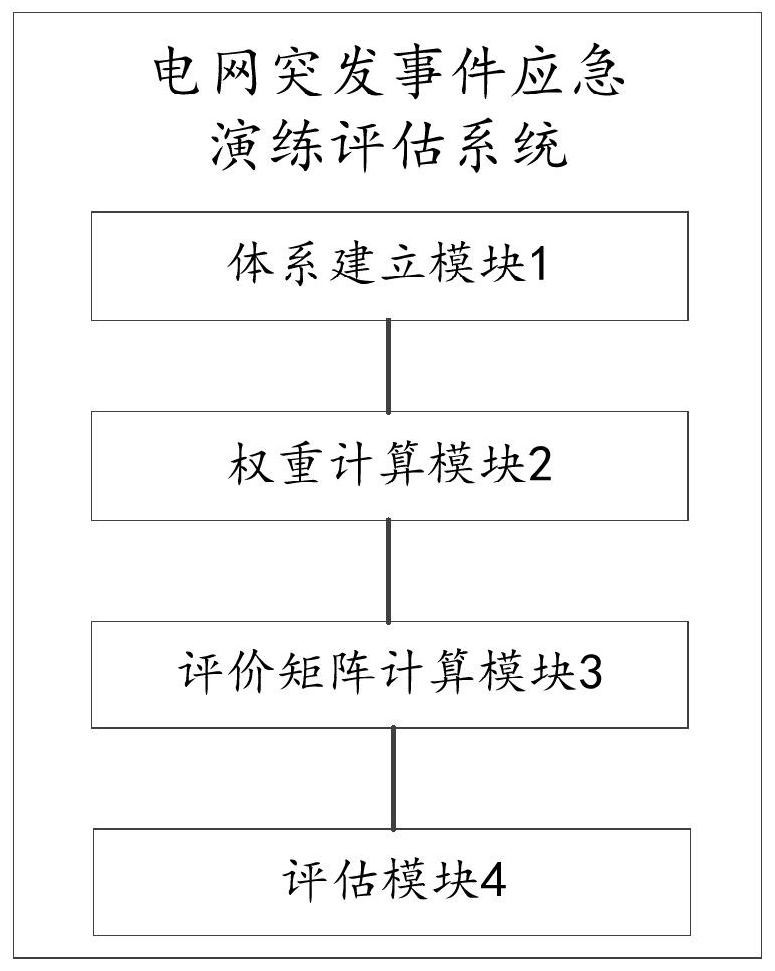

Power grid emergency event emergency drill assessment method and device and storage medium

The invention discloses a power grid emergency event emergency drill evaluation method and device and a storage medium. The method comprises the steps of establishing a power grid emergency event emergency drill evaluation index system according to an emergency drill role; calculating according to an analytic hierarchy process to obtain the weight of each evaluation index in each hierarchy in the evaluation index system; calculating a single-index factor evaluation matrix according to a scoring interval in which a comment of each evaluation index is located; and calculating according to the weight and the single index factor evaluation matrix to obtain an evaluation result of the power grid emergency event emergency drill evaluation. Through implementation of the method, a power grid emergency event emergency drill evaluation index system is established in a responsibility division mode, the weight of each evaluation index in each level in the evaluation index system is calculated by adopting an analytic hierarchy process, and a single-index factor evaluation matrix of each evaluation index is obtained through an expert scoring mode. And finally, comprehensive evaluation of each index is realized in combination with the calculated weight and the single-index factor evaluation matrix, and the reliability is high.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

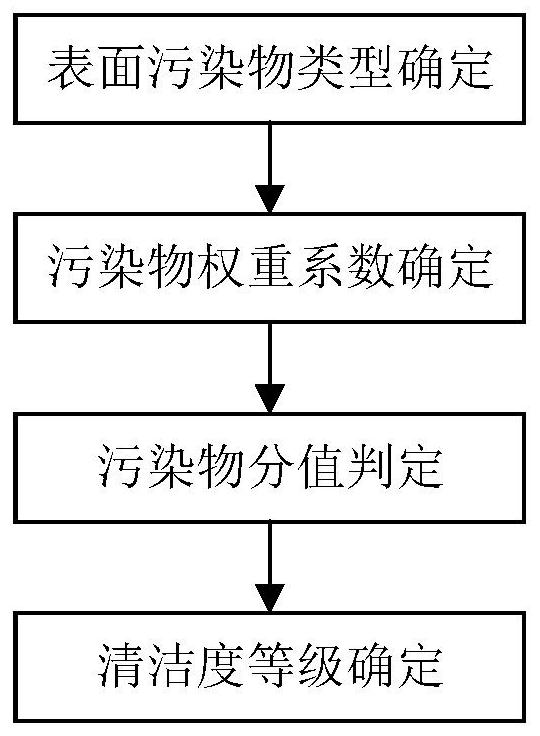

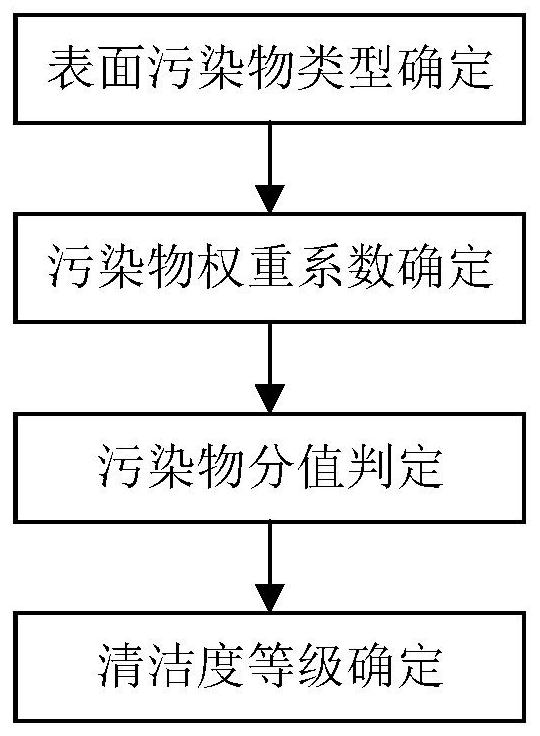

Construction-forming-oriented substrate surface cleanliness evaluation method

ActiveCN112903709AQuantitative evaluationOptically investigating flaws/contaminationSurface cleaningEnvironmental engineering

The invention discloses a base material surface cleanliness evaluation method for metal base material construction and formation, which comprises the following steps of: setting weight coefficients corresponding to oil stains, particles and cuttings according to a test result, detecting pollution scores of different pollutants by using different methods respectively, and calculating the product sum of all pollution weight coefficients and pollution scores, so that the surface cleanliness is quantitatively represented. The invention provides an accurate and systematic surface cleanliness evaluation method for metal base material construction and forming. The pollutant weight coefficient is determined on the basis of the degrees of adverse effects of different pollutants on the healing of the substrate interface; and different detection methods are adopted for different pollutants, and pollution scores of the different pollutants are determined. According to the method, the pollution value is determined according to the sum of the products of the weight coefficients of the pollutants and the pollution scores, the contrast relation is formulated, and finally the cleanliness grade is determined, so that the surface cleanliness of the base material is accurately and quantitatively evaluated.

Owner:DALIAN UNIV OF TECH

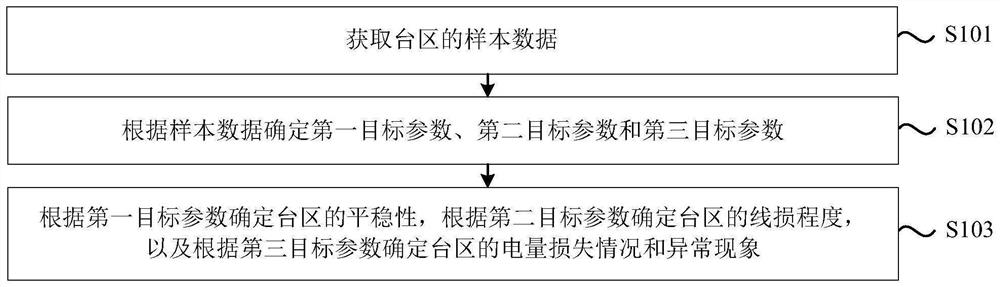

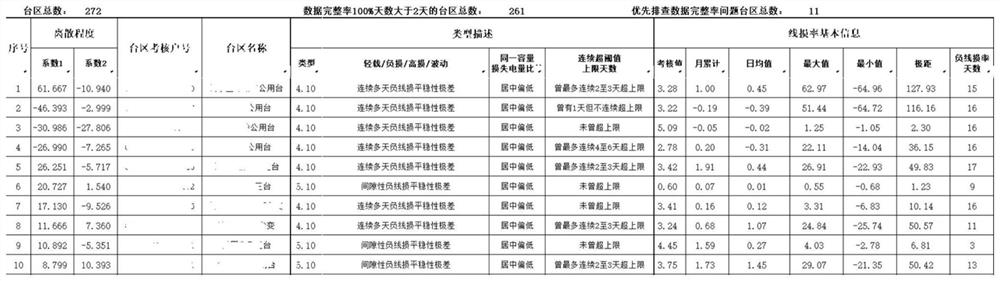

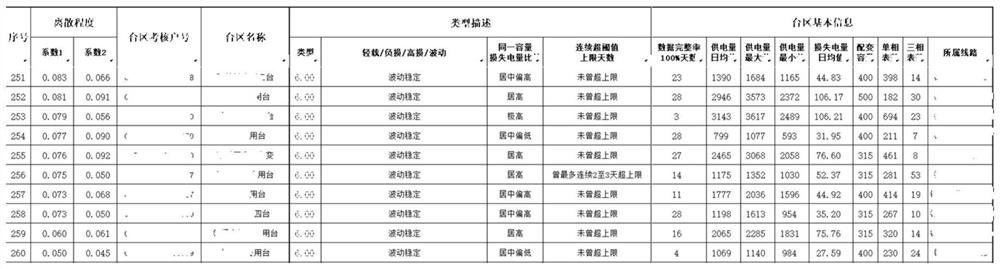

Transformer area line loss evaluation method and device, electronic equipment and storage medium

PendingCN114565324AComprehensive assessmentQuantitative evaluationResourcesInformation technology support systemTransformerReliability engineering

The invention discloses a transformer area line loss evaluation method and device, electronic equipment and a storage medium. The method comprises the following steps: acquiring sample data of a transformer area; determining a first target parameter, a second target parameter and a third target parameter according to the sample data; and determining the stability of the transformer area according to the first target parameter, determining the line loss degree of the transformer area according to the second target parameter, and determining the electric quantity loss condition and the abnormal phenomenon of the transformer area according to the third target parameter. According to the technical scheme, the stability, the line loss degree, the electric quantity loss condition and the abnormal phenomenon of the transformer area are determined through the first target parameter, the second target parameter and the third target parameter, and the line loss condition of the transformer area can be evaluated comprehensively and quantitatively.

Owner:GUANGDONG POWER GRID CO LTD +1

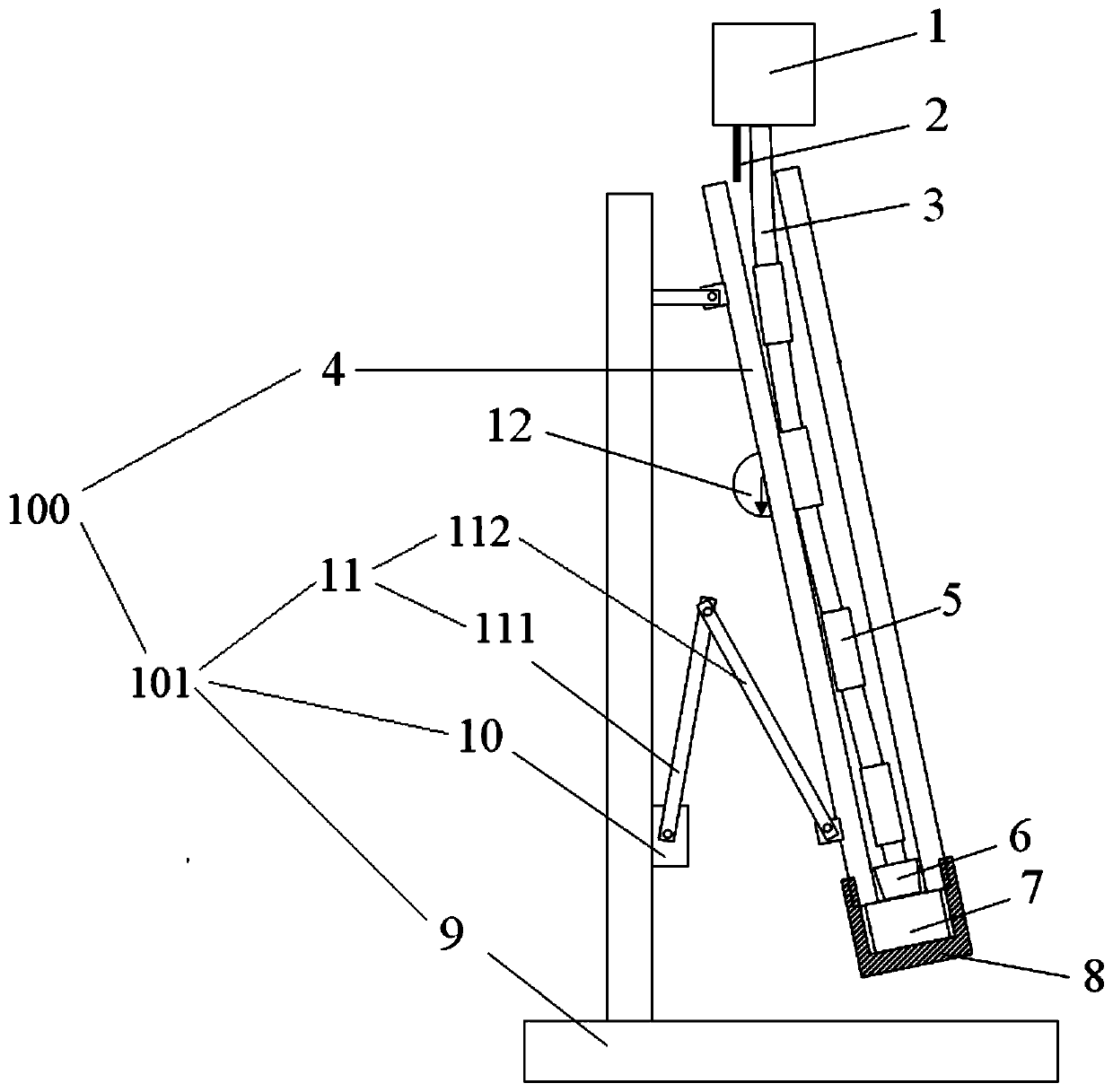

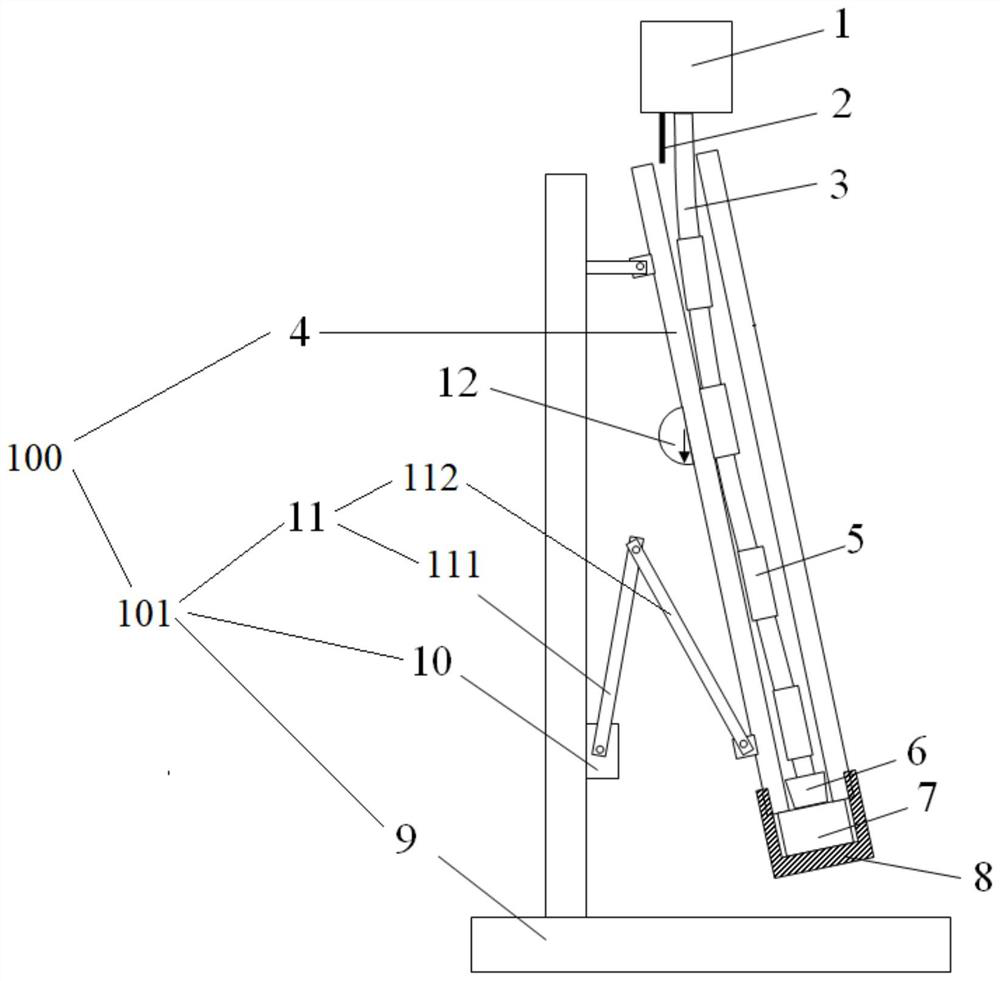

Casing buckling evaluation system in inclined shaft cementing process

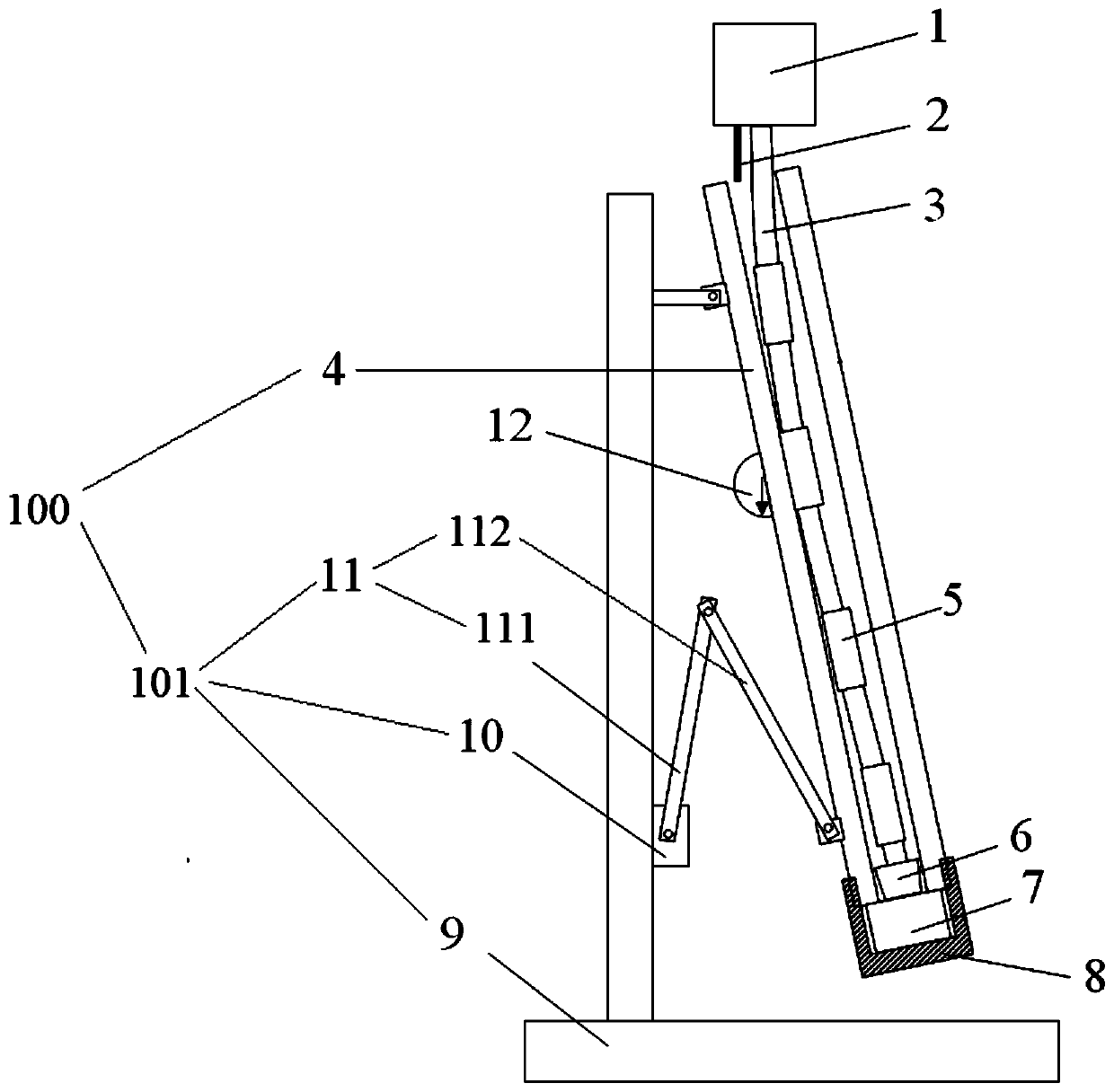

ActiveCN111366393ATo achieve the purpose of buckling evaluationRealize monitoringStructural/machines measurementWell cementingControl cell

The invention relates to a casing buckling evaluation system in an inclined shaft cementing process. The system comprises a well wall simulation unit and an inclination control unit, the well wall simulation unit defining a cavity to simulate a well wall, and the inclination control unit controlling the well wall simulation unit to be in an inclined state; a hollow sleeve extending into the cavity; a sleeve fixing device used for fixing the top of the hollow sleeve; a sleeve shoe, arranged at the bottom of the cavity and connected with the bottom of the hollow sleeve so as to seal the hollow sleeve; a Cement paste storage and collection device, a cement paste control valve being arranged on the cement paste storage and collection device so as to control cement paste in the cement paste storage and collection device to flow into the cavity; a well bottom sleeve, connected with the well wall simulation unit; an annulus pressure sensor; and a detection device, used for detecting the vertical tension, torque and displacement of the hollow sleeve so as to perform buckling evaluation on the hollow sleeve according to the pressure value detected by the annular pressure sensor and the vertical tension, torque and displacement of the hollow sleeve. The system is simple in structure, simple and convenient to operate and good in feasibility.

Owner:XINJIANG ZHENGTONG OIL & GAS CO LTD

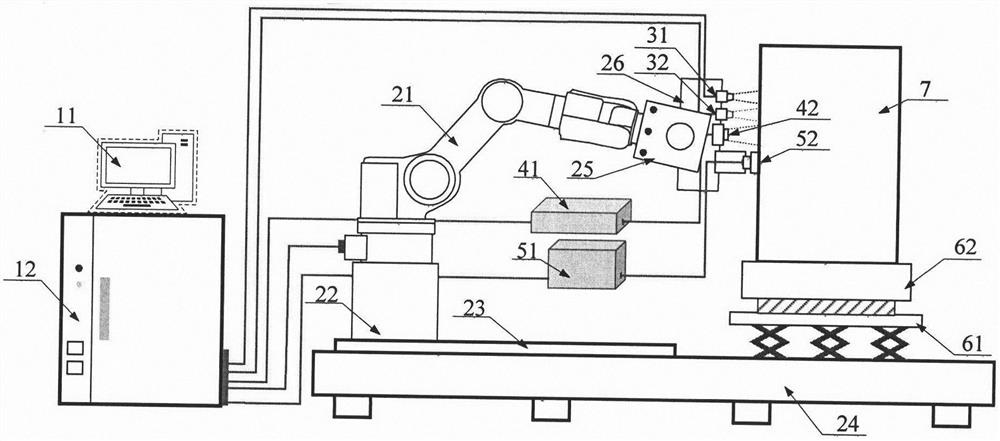

Composite evaluation equipment and method for aluminum alloy laser welding structure

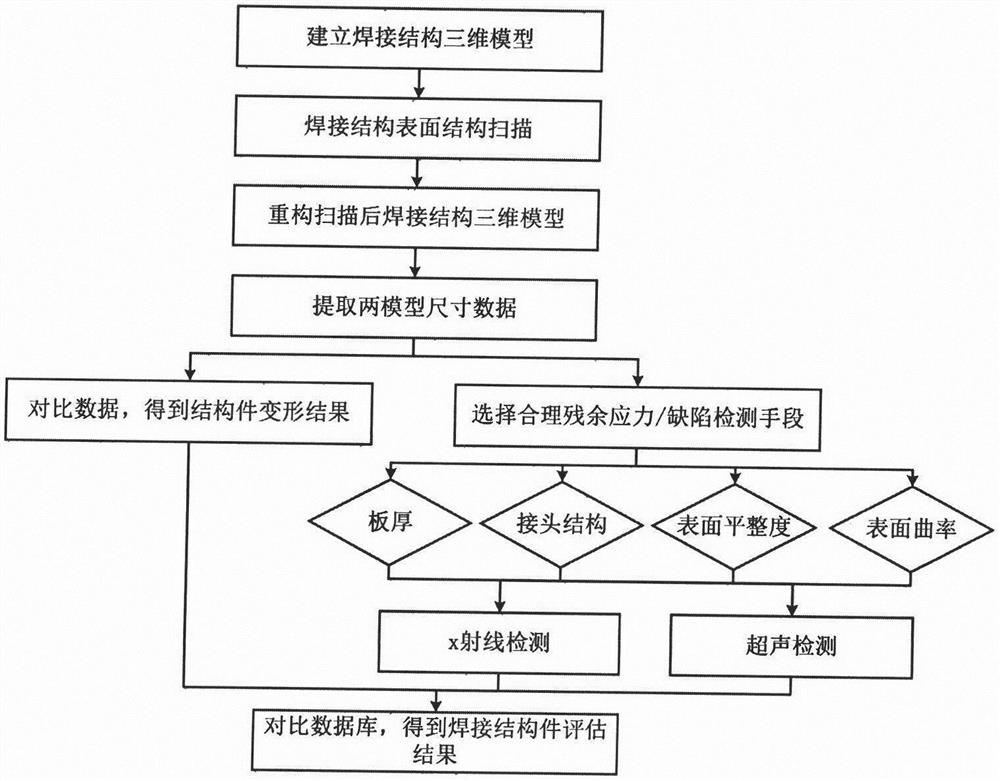

ActiveCN113281363AComprehensive assessmentEffective evaluationAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis using wave/particle radiationCollection analysisStatistical analysis

The invention discloses composite evaluation equipment and method for an aluminum alloy laser welding structure. The equipment mainly comprises a control system, a movement system, a welding seam locating and tracking system, a portable X-ray diffractometer, an ultrasonic detector and a detection working platform. The invention aims to realize the detection and evaluation of the welding structure on the premise of not damaging the aluminum alloy welding structure. The welding seam locating and tracking system is used for carrying out recognition, positioning and three-dimensional shape reconstruction on a welding seam, and a specific quality detection means is selected according to the geometrical characteristics of a weldment. A six-axis robot carries the welding seam locating and tracking system, theportable X-ray diffractometer and the ultrasonic detector. Detection of the aluminum alloy laser welding structure is achieved, and detection data are collected and analyzed to obtain an evaluation result. A detection and evaluation means including welding seam locating and scanning, three-dimensional model reconstruction, parameter extraction, reasonable detection means selection, data statistical analysis and conclusion evaluation is formed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

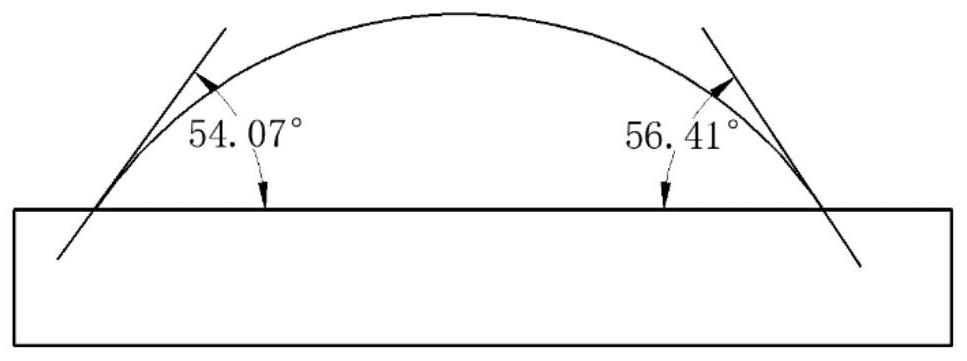

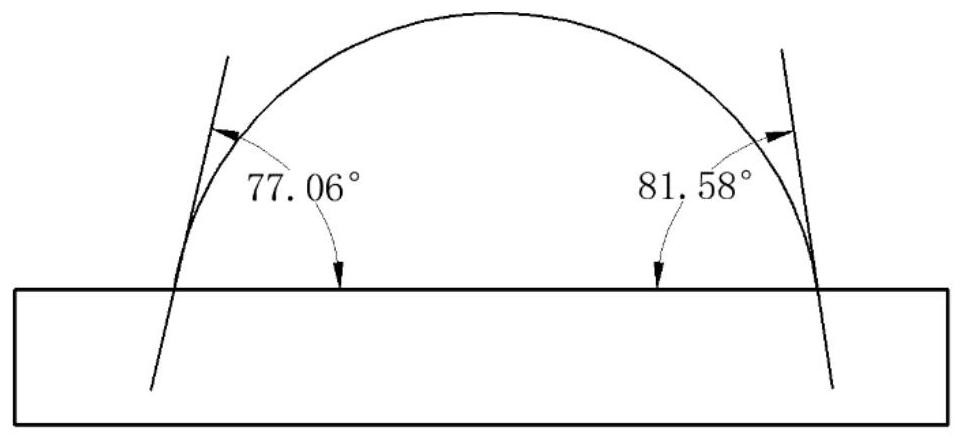

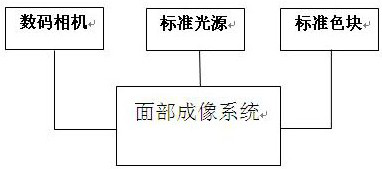

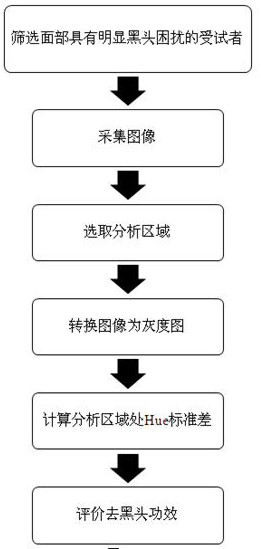

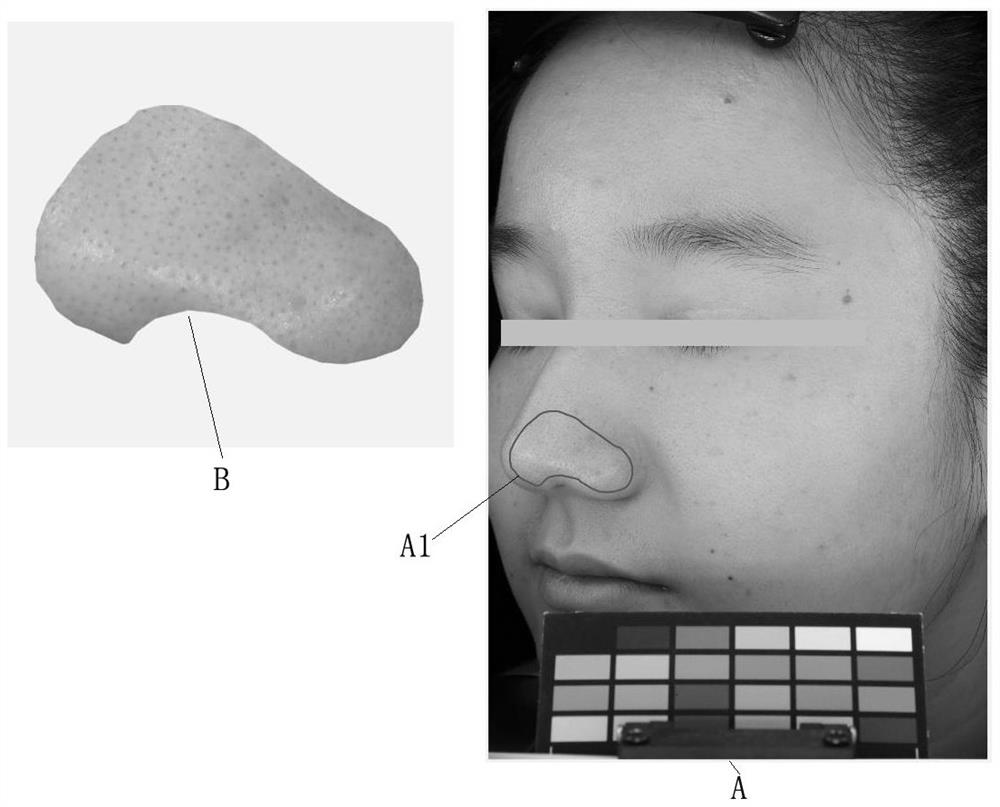

Human body efficacy evaluation method for blackhead removing cosmetics

PendingCN113854961AReduce dependenceObjective evaluationDiagnostic recording/measuringSensorsHuman bodySkin colour

The invention relates to a human body efficacy evaluation method for blackhead removing cosmetics. The method is characterized by comprising the following steps: A, acquiring facial images of a subject before and after using a to-be-tested product through a face imaging system; B, selecting a test area of the face image acquired in the step A, and calculating Hue standard deviation of the selected area of the face image before and after the to-be-tested product is used; and C, evaluating the blackhead removing effect of the to-be-tested product according to the Hue standard deviation calculated in the step B. The method has the following beneficial effects that the dependence on a semi-subjective expert evaluation method is reduced, blackhead removal can be evaluated more objectively, quickly and quantitatively, and the result has good repeatability. According to the method, the blackhead color is different from surrounding skin color, reduction of the number of blackheads is considered, reduction of the oxidation degree of the blackheads is also considered, and the blackhead removing effect of the cosmetics is evaluated more comprehensively.

Owner:PROYA COSMETICS

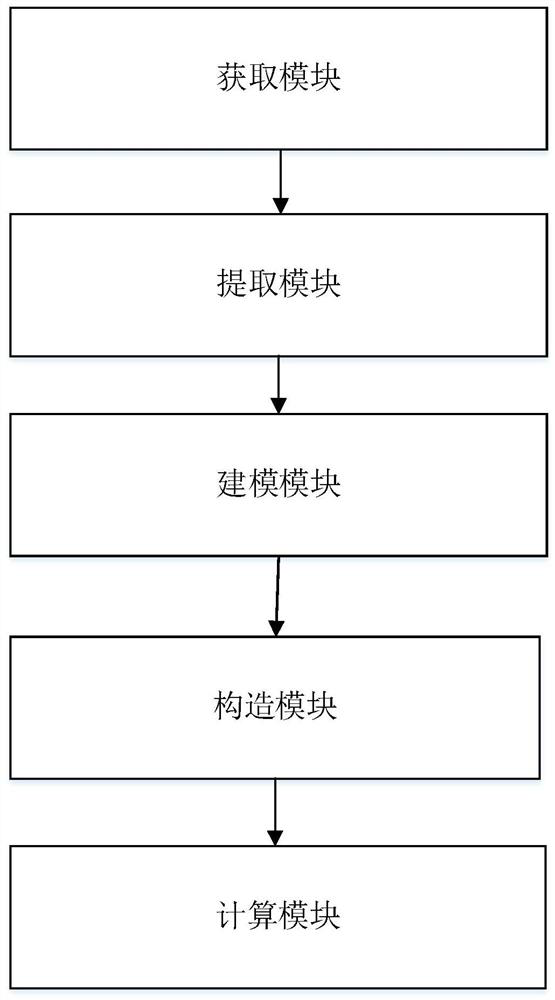

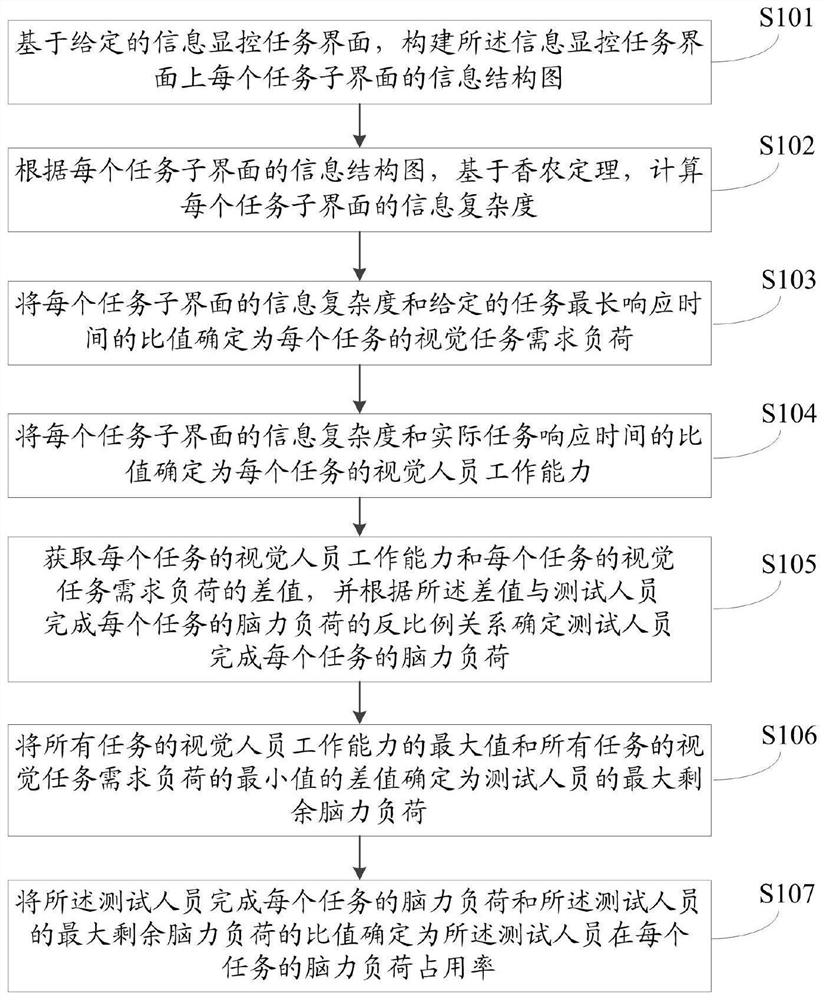

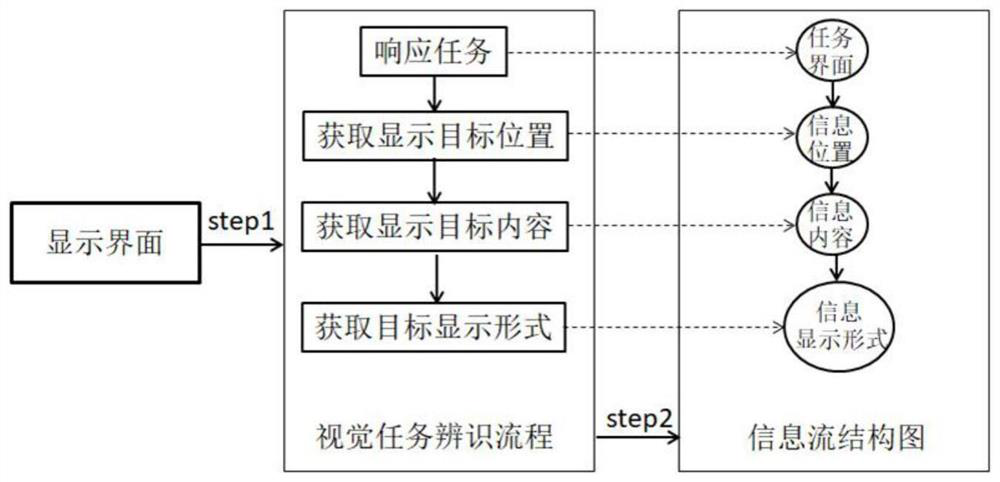

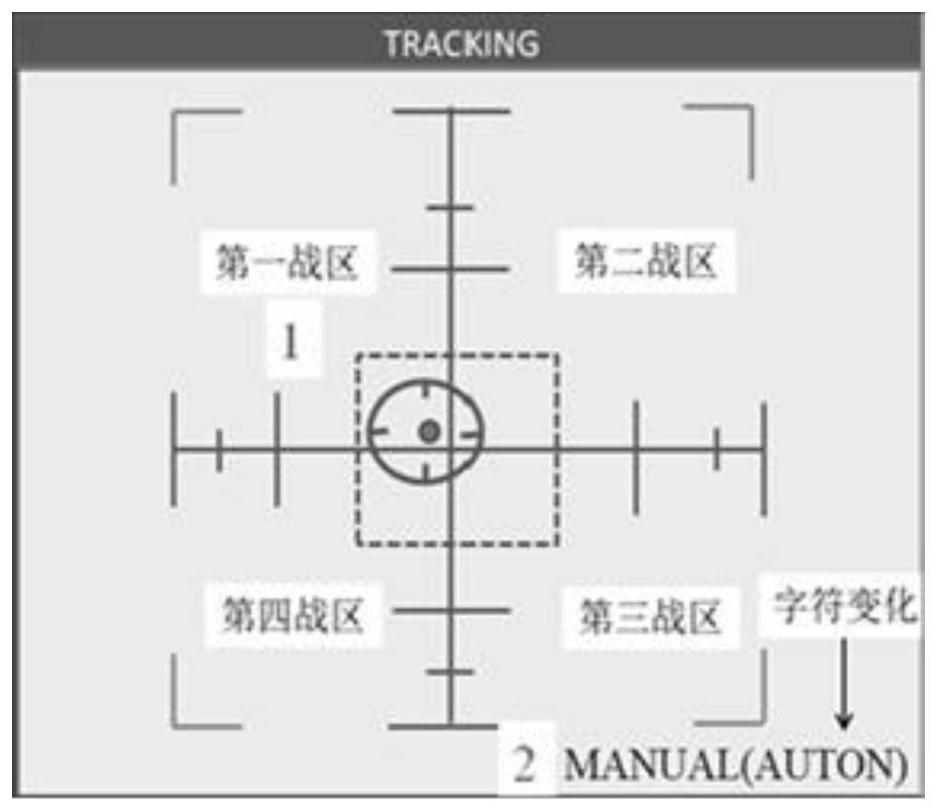

Visual task mental load quantitative evaluation method and system

ActiveCN112635048AReal-time evaluationQuantitative evaluationHealth-index calculationMedical automated diagnosisTask demandSimulation

The invention relates to a visual task mental load quantitative evaluation method and system. The method comprises the steps: firstly constructing an information structure diagram of each task sub-interface on an information display and control task interface based on a given information display and control task interface, and calculating the information complexity of each task sub-interface according to the information structure diagram of each task sub-interface based on the Shannon theorem; then calculating the visual task demand load and the visual personnel working capability of each task according to the information complexity, and calculating the mental load and the maximum residual mental load of the tester for completing each task by utilizing the visual task demand load and the visual personnel working capability; and finally, according to the mental load and the maximum residual mental load, processing and quantifying the mental load occupancy rate of each task of the tester in the task process, thereby realizing real-time and quantitative evaluation of the mental load.

Owner:BEIHANG UNIV

Method for evaluating organic surface coating effect of special titanium dioxide for plastics

InactiveCN112540146AQuantitative evaluationAccurate evaluationWeighing by removing componentPhysical chemistryMaterials science

The invention belongs to the technical field of chemical engineering, and relates to a method for evaluating the organic surface coating effect of special titanium dioxide for plastics. The inventionaims to provide a method for evaluating the organic surface coating effect of special titanium dioxide for plastics. The method comprises the following steps of: A, drying titanium dioxide, cooling the titanium dioxide to room temperature, adding the titanium dioxide into desalted water, performing stirring, and observing and recording the hydrophobic condition of the titanium dioxide; b, heatingthe desalted water containing the titanium dioxide in the step A, carrying out condensation reflux in the heating process, cooling after heating is finished, and performing filtering to obtain filtrate and residues; and C, calcining the residues, performing cooling and weighing sequentially, and measuring the turbidity of the filtrate. The method provided by the invention can quantitatively and accurately evaluate the organic surface coating effect of the titanium dioxide special for different plastics.

Owner:CHONGQING TITANIUM IND OF PANGANG GROUP

Real-time monitoring device and method for cold spraying coating and interface defects of cold spraying coating

PendingCN114544755AAvoid intensityAvoid the situationTotal factory controlMaterial magnetic variablesSurface engineeringData acquisition

The invention discloses a real-time monitoring device and method for cold spraying coating and interface defects thereof, and belongs to the field of electromagnetic nondestructive testing technology and surface engineering. The real-time monitoring device mainly comprises a signal generation module, a magnetic field excitation module, a motion control module, a data acquisition module and a device fixing module. The signal generation module comprises a signal generator and a power amplifier; the magnetic field excitation module comprises a U-shaped magnet yoke, a magnet exciting coil and a signal receiver; the motion control module is mainly composed of a mechanical arm. The data acquisition module comprises a voltage amplifier, a data acquisition card and an upper computer; the device fixing module comprises a support, a base and a clamp. The magnetic field excitation module and the cold spraying device synchronously move in the monitoring process, real-time monitoring on defects of a base body and a coating of a ferromagnetic material in the cold spraying process is achieved, and the unforeseen circumstances of strength failure, coating stripping and the like of a remanufactured part are avoided.

Owner:NANJING INST OF TECH

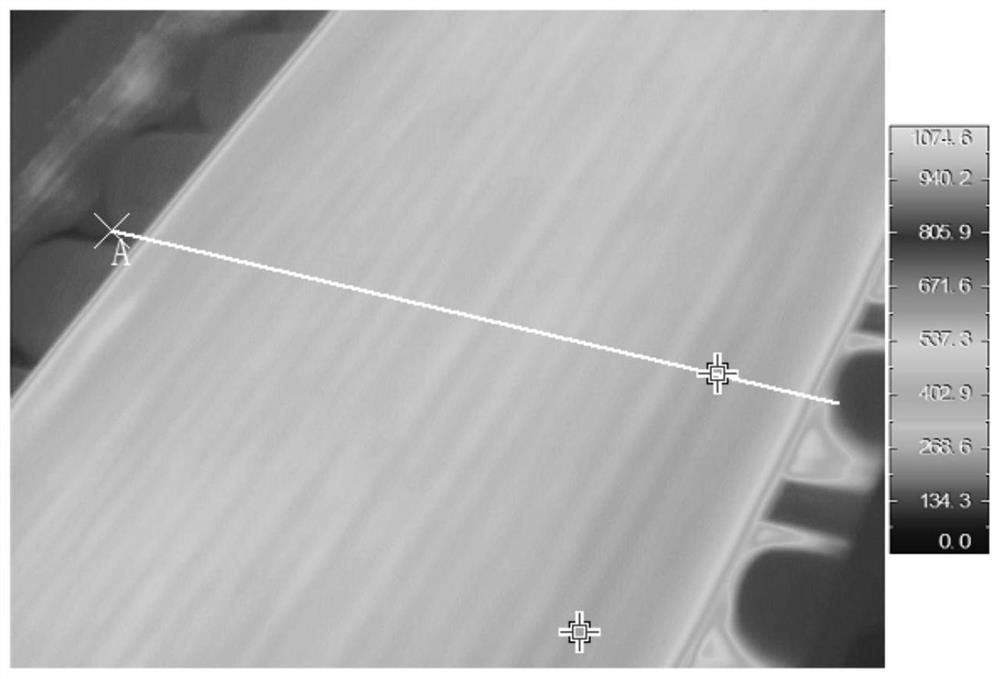

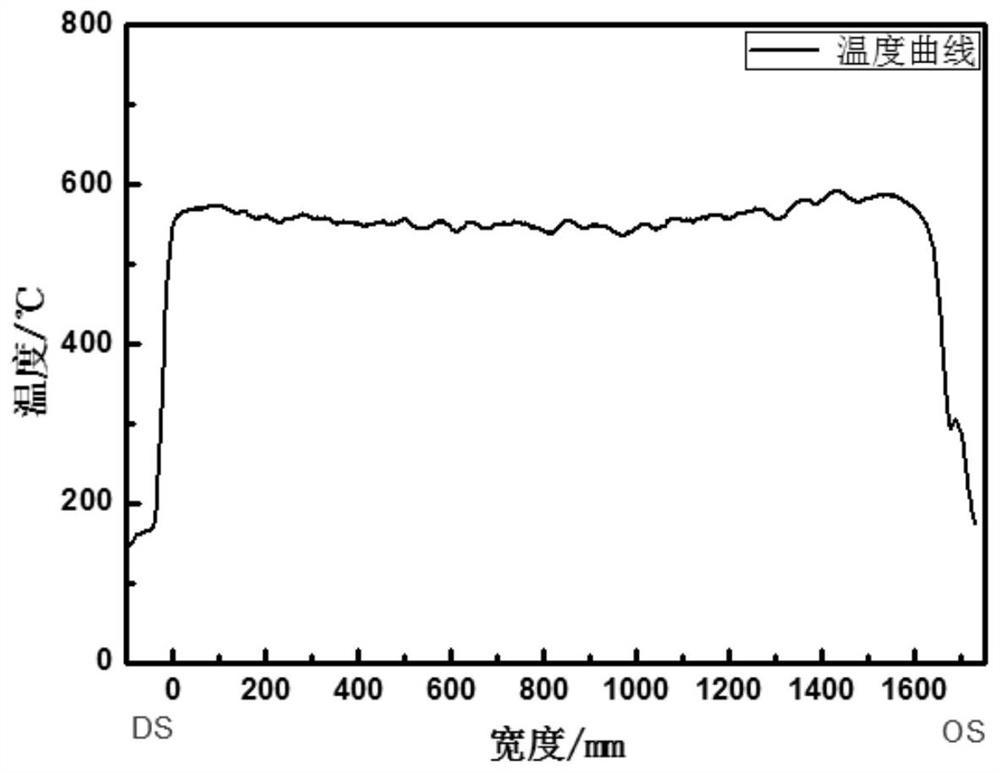

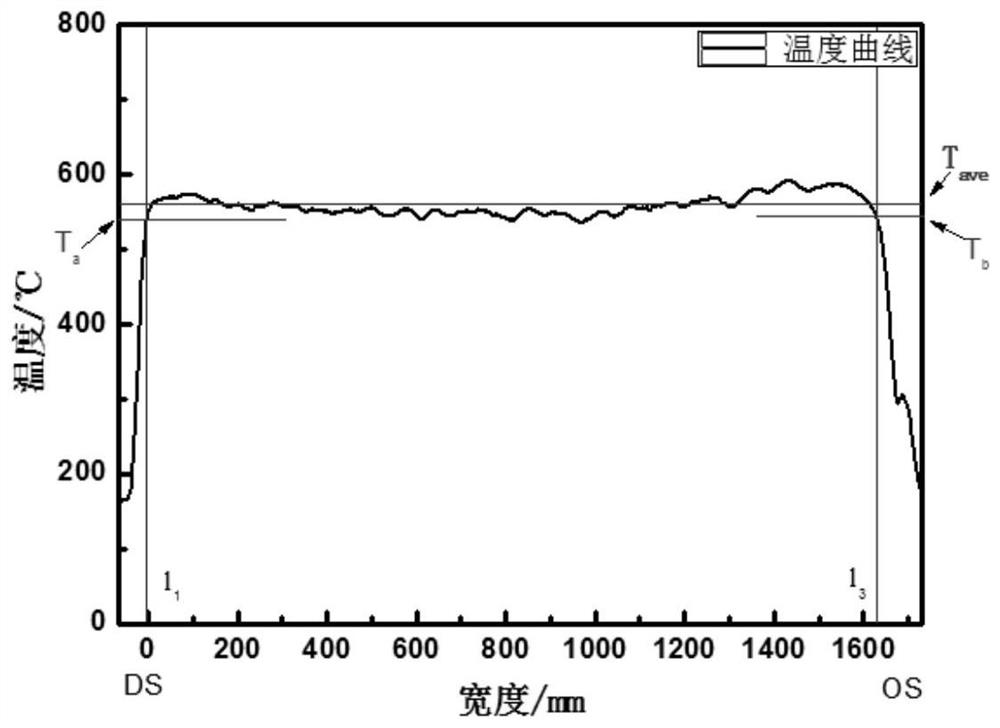

Method for evaluating temperature uniformity of hot rolled strip steel in width direction

ActiveCN113378370ASimple edge temperature dropObjective edge temperature dropDesign optimisation/simulationResourcesThermodynamicsEngineering

The invention discloses a method for evaluating the temperature uniformity of hot-rolled strip steel in the width direction, and relates to the technical field of hot-rolled strip steel. The invention discloses a method for evaluating the temperature uniformity of hot rolled strip steel in the width direction. Comprising the following steps: adding a temperature measuring line and generating temperature data of the temperature measuring line; processing the data to determine the edge position point of the strip steel; converting the relative coordinates into strip steel width absolute position points; and finally, determining the average temperature value of the strip steel in the width direction in an integral mode, wherein the point corresponding to the temperature data, exported through analysis software, of the temperature measuring line A is the relative position point B of the shooting picture space, and the position point without the actual width of the strip steel needs to be converted. The method further comprises the step of calculating the edge temperature drop values of the operation side and the transmission side of the hot-rolled strip steel, so that the temperature drop values of the operation side and the transmission side of the hot-rolled strip steel in the width direction are simply, conveniently and objectively calculated; and finally, quantitatively evaluating the temperature uniformity of the hot-rolled strip steel.

Owner:MAANSHAN IRON & STEEL CO LTD

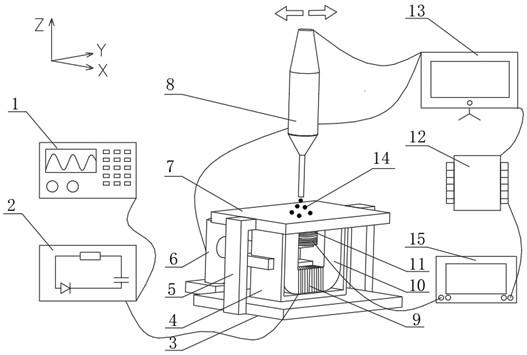

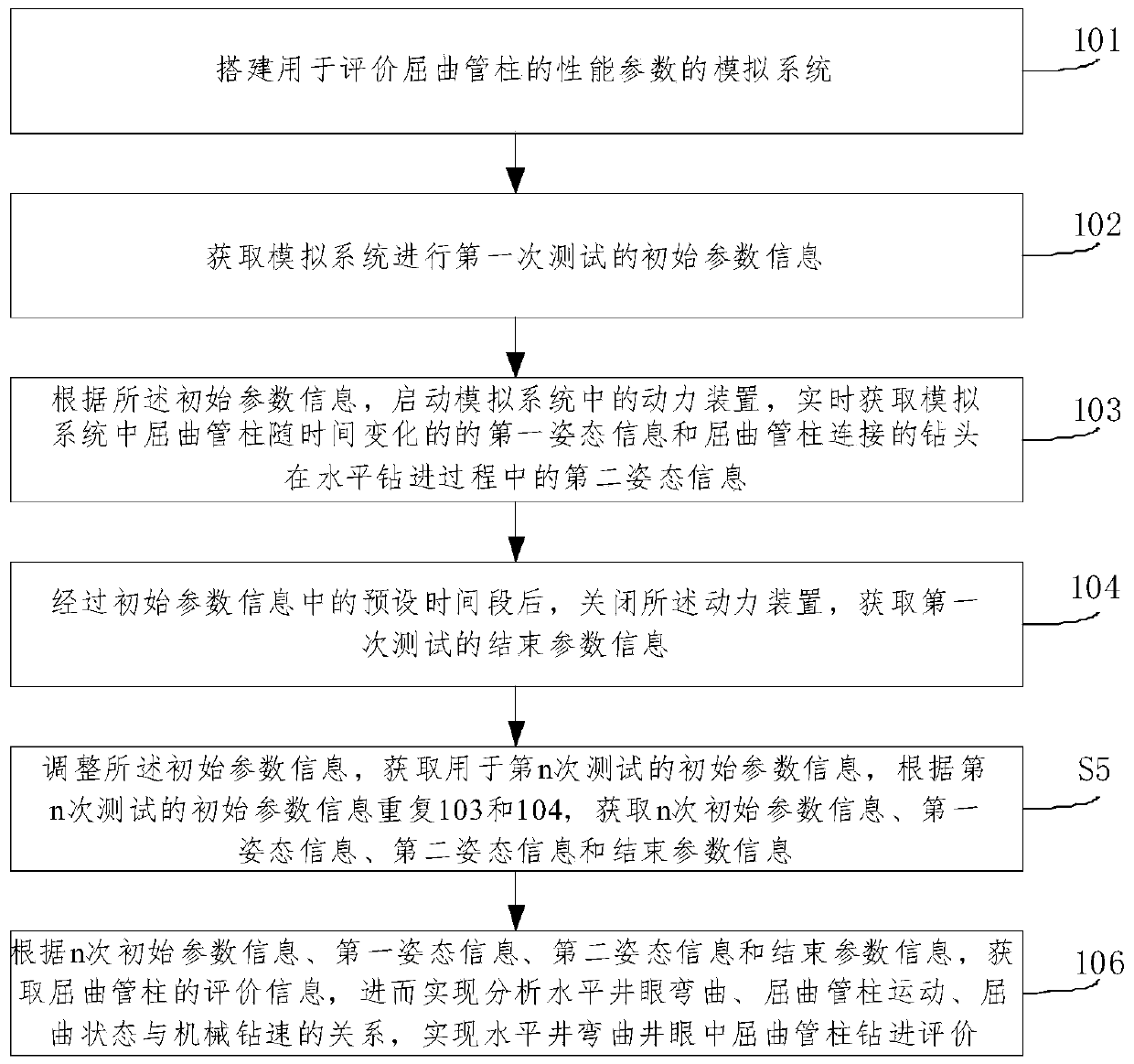

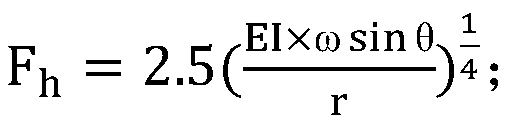

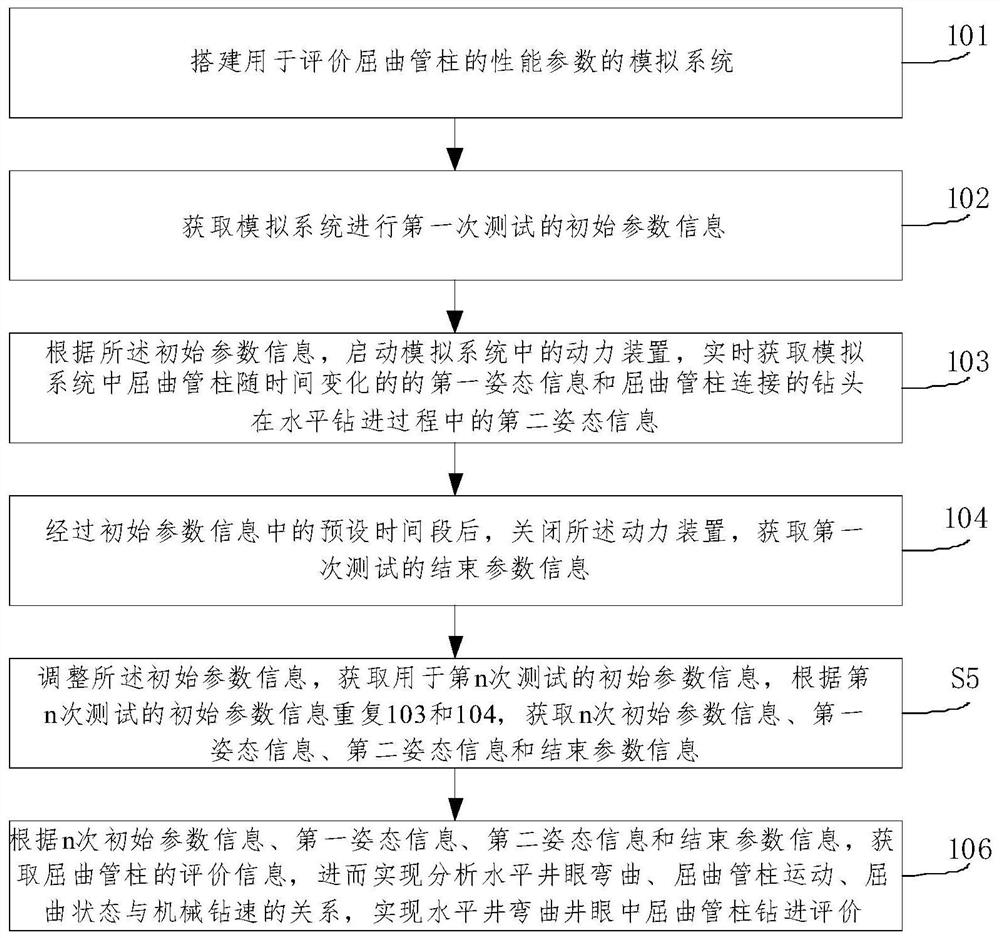

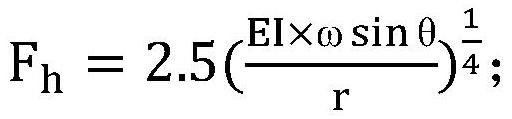

Method for evaluating drilling of buckling tubular column in bent horizontal borehole

ActiveCN111380712AQuick evaluationQuantitative evaluationStructural/machines measurementHorizontal wellsEngineering

The invention discloses a method for evaluating drilling of a buckling tubular column in a bent horizontal borehole. The method comprises the steps of 1, building a simulation system used for evaluating performance parameters of the buckling tubular column; 2, obtaining initial parameter information of the simulation system in a first test; 3, starting a power device in the simulation system, andobtaining first posture information, which changes along with time, of the buckling tubular column and second posture information of a drill bit in the horizontal drilling process in real time; 4, turning off the power device, and obtaining ending parameter information of the first test; 5, adjusting the initial parameter information, obtaining the initial parameter information of the nth test, repeating the test according to the initial parameter information, and obtaining all information of the n times of testing; and 6, obtaining evaluation information of the buckling tubular column according to all the information of the n times of testing. By means of the method, the drilling state of the tubular column in the bent horizontal borehole can be evaluated rapidly and quantitatively, and the accuracy and real-time performance of evaluation are guaranteed.

Owner:XINJIANG ZHENGTONG OIL & GAS CO LTD

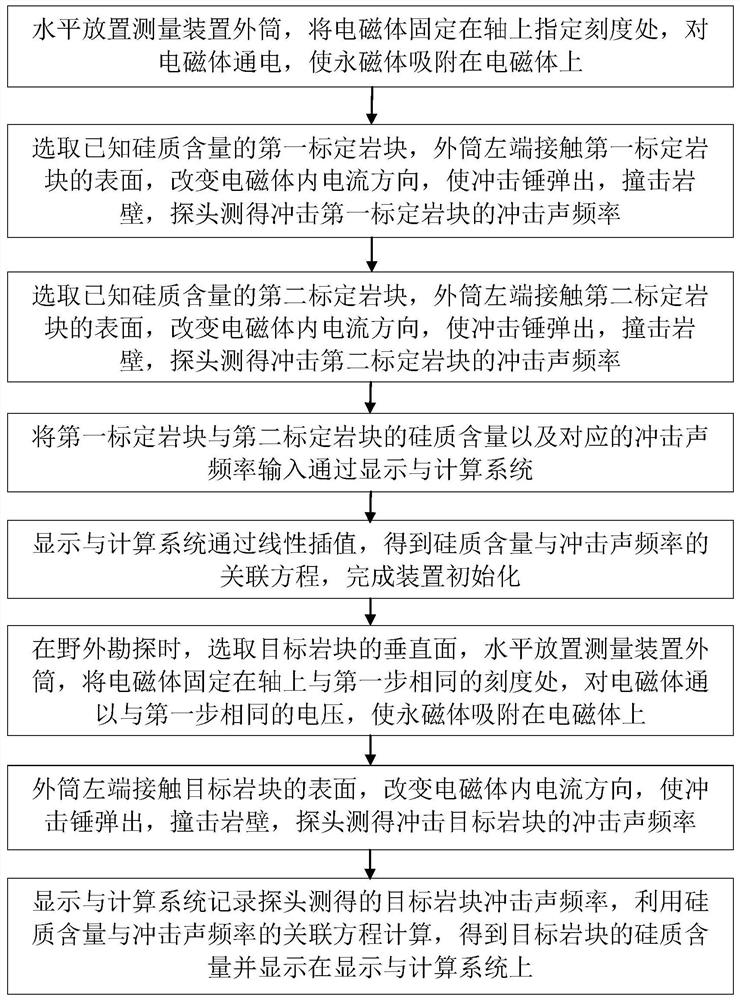

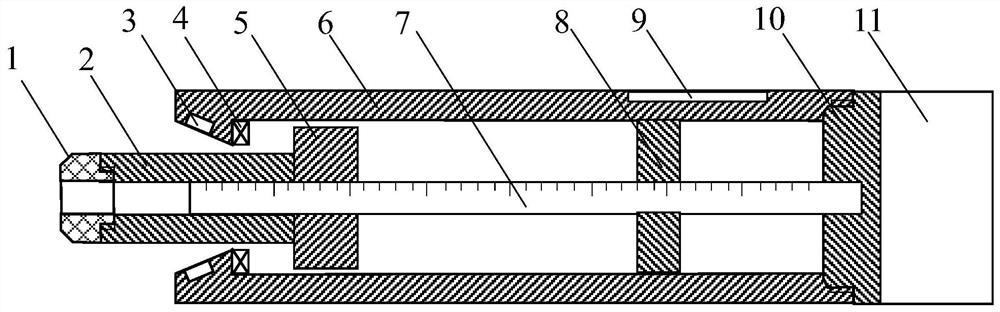

Method for rapidly evaluating siliceous content of field shale

PendingCN113720906ASimple and fast operationHigh feasibilityAnalysing solids using sonic/ultrasonic/infrasonic wavesImpact hammerGeophysics

The invention relates to a method for rapidly evaluating the siliceous content of field shale, the method comprises the following steps: horizontally placing an outer cylinder, fixing an electromagnet at a specified scale on a shaft, electrifying the electromagnet, and enabling a permanent magnet to be adsorbed on the electromagnet; selecting a calibration rock block with known siliceous content, enabling the left end of an outer cylinder to make contact with the surface of the calibration rock block, and changing the current direction in the electromagnet so that an impact hammer pops up and impacts a rock wall, and a probe measures the impact sound frequency of the calibration rock block; inputting the siliceous content of the calibrated rock block and the corresponding impact sound frequency into a display and calculation system; obtaining an associated equation of the siliceous content and the impact sound frequency through linear interpolation; repeating the second step for the vertical surface of the target rock block to obtain the impact sound frequency of the target rock block; and recording the impact sound frequency of the target rock measured by the probe, calculating by using the associated equation of the siliceous content and the impact sound frequency to obtain the siliceous content of the target rock, and displaying the siliceous content on the display and calculation system to realize rapid evaluation of the siliceous content.

Owner:刘亢

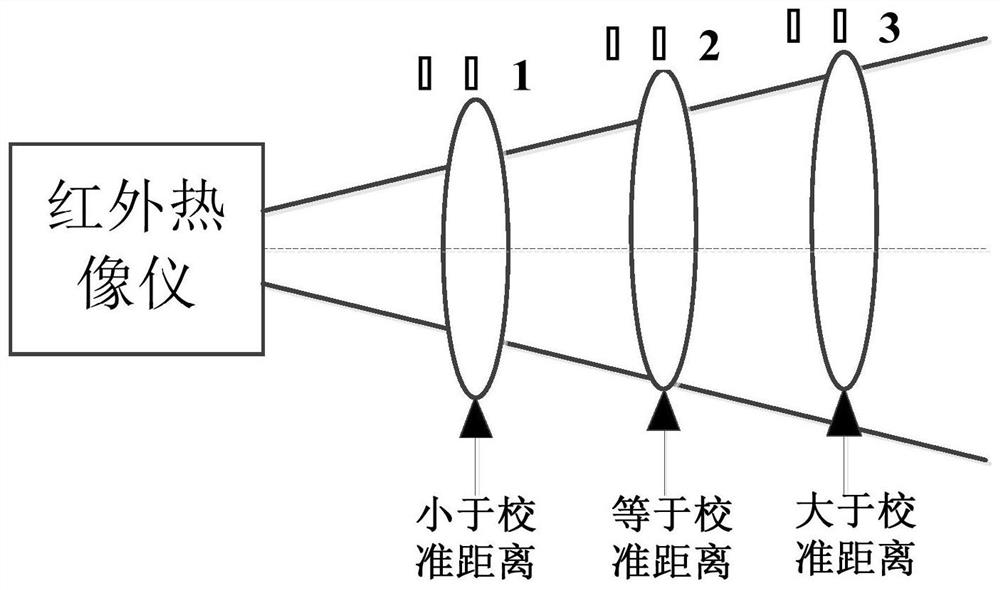

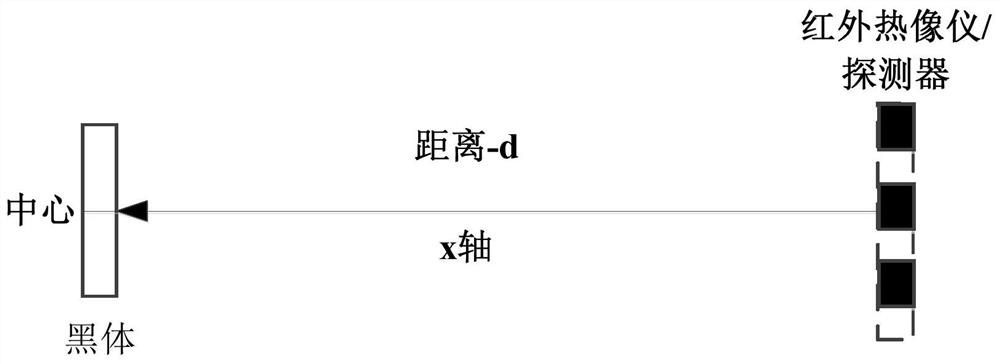

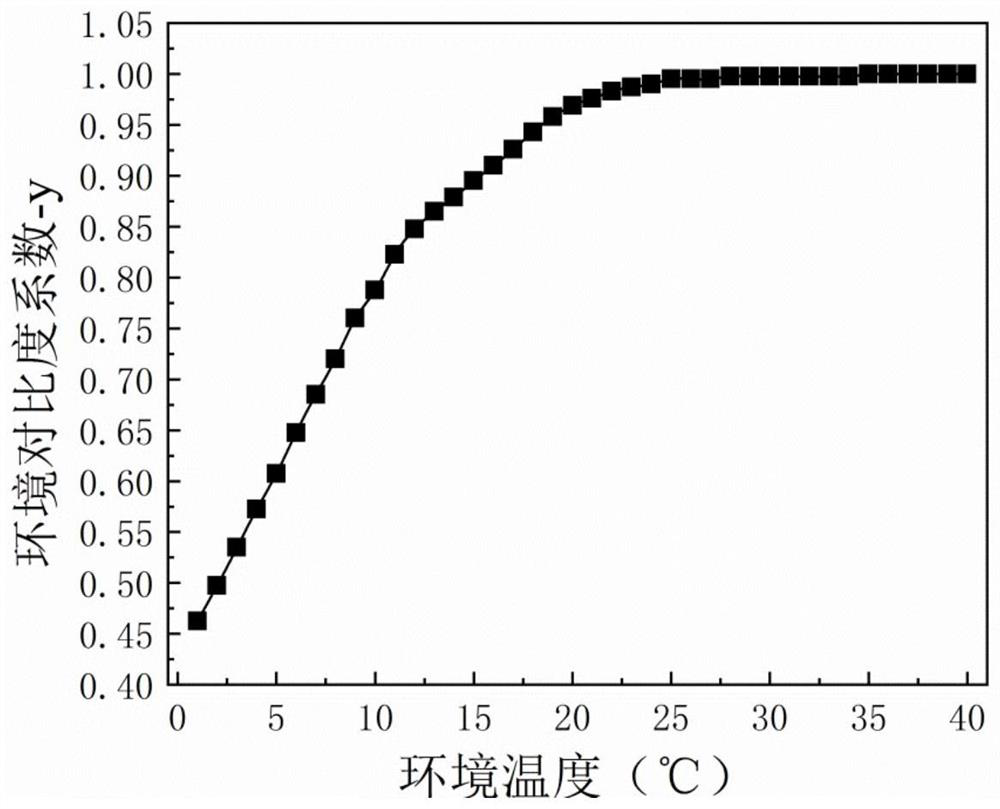

Infrared temperature measurement method for reducing ambient temperature contrast

PendingCN113701901AEasy to implementQuantitative evaluationRadiation pyrometryChemistryInfrared temperature measurement

The invention discloses an infrared temperature measurement method capable of reducing environment temperature contrast. The method may include the steps of: determining a constant blackbody temperature source TB; when the measurement distance is determined, obtaining the specific gravity relation between the black body temperature TB and the environment temperature TU at different environment temperatures by changing the environment temperature TU; when the environment temperature is determined, obtaining the specific gravity relation between the environment temperature TU and the black body temperature TB under different measurement distances by changing the measurement distances; and calculating the actual temperature of the measured object through the proportionality coefficient. According to the invention, the measurement error caused by the environment temperature contrast can be effectively reduced, the measurement is accurate, and the measurement error can be effectively reduced.

Owner:北京市计量检测科学研究院

A Drilling Evaluation Method of Buckling String in Curved Horizontal Wellbore

ActiveCN111380712BQuick evaluationQuantitative evaluationStructural/machines measurementHorizontal wellsClassical mechanics

Owner:XINJIANG ZHENGTONG OIL & GAS CO LTD

Casing buckling evaluation system in the cementing process of deviated wells

ActiveCN111366393BTo achieve the purpose of buckling evaluationRealize monitoringStructural/machines measurementWell cementingControl cell

Owner:XINJIANG ZHENGTONG OIL & GAS CO LTD

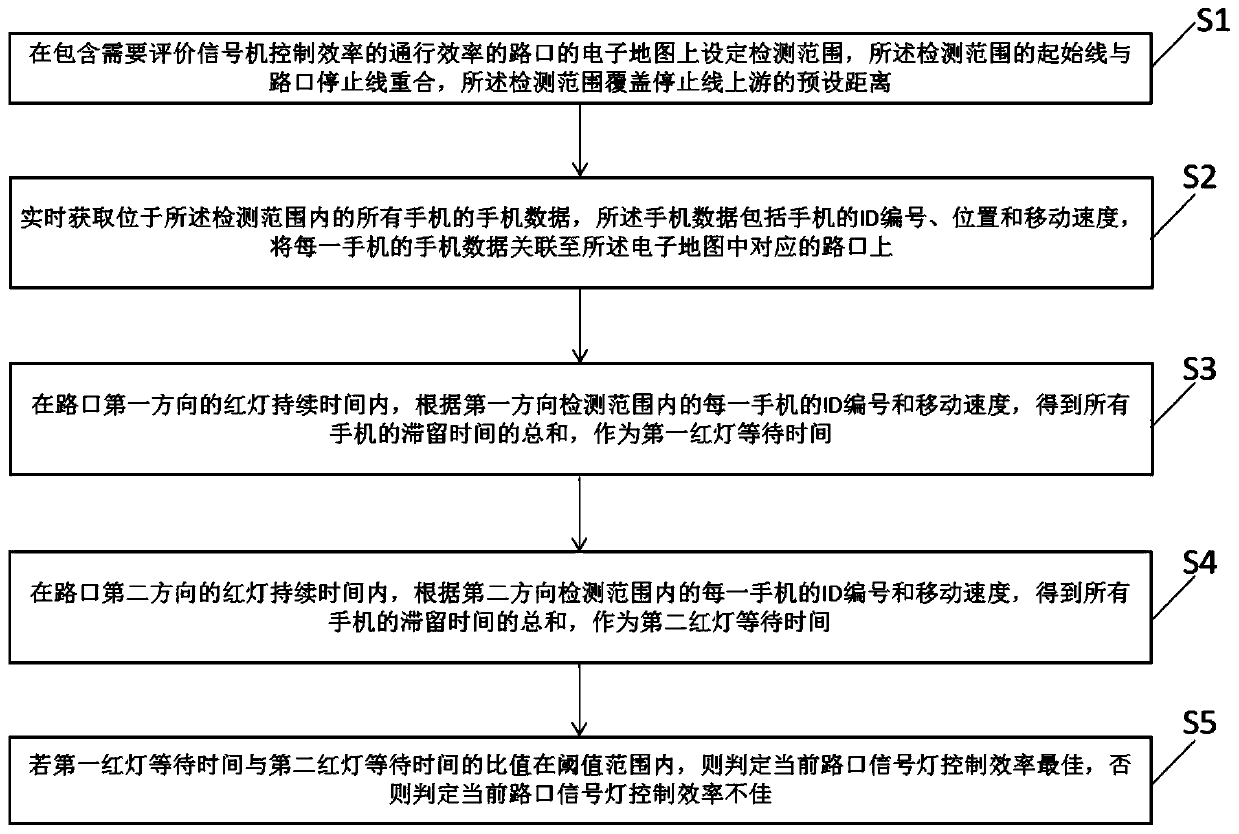

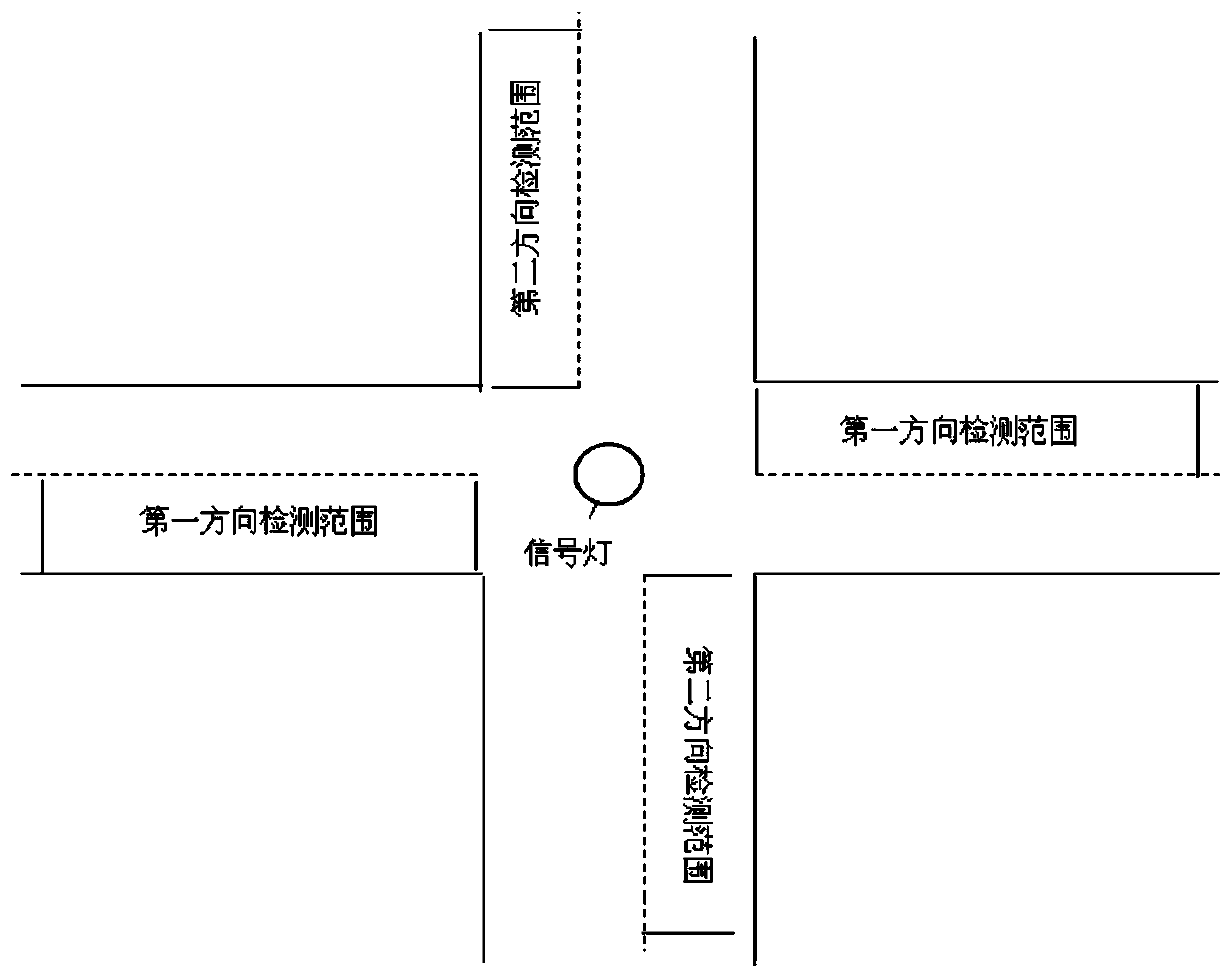

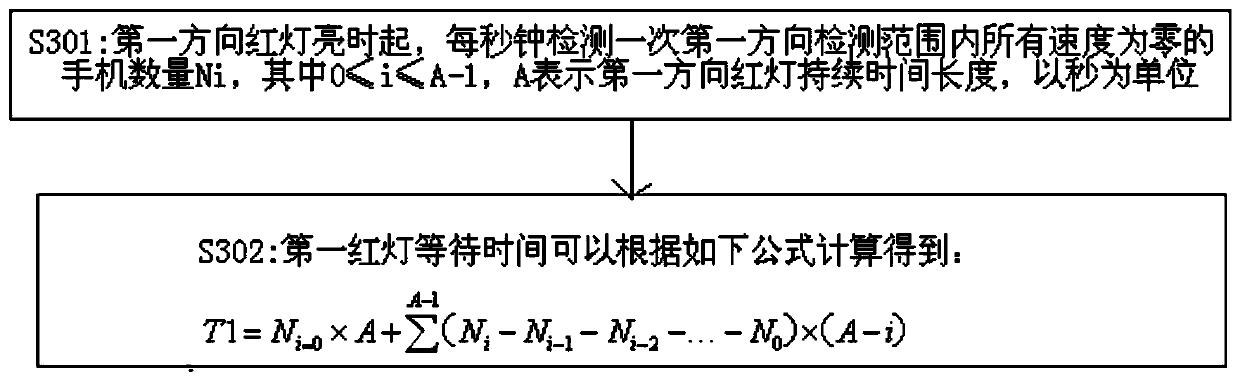

Method and system for evaluating control efficiency of intersection signal machine using mobile phone mobile data

ActiveCN106997668BQuantitative evaluationDetection of traffic movementTraffic control supervisionSignal lightEmbedded system

The invention provides a method and a system of using cell phone mobile data to evaluate intersection signal control efficiency. A detection range is set in an electronic map comprising an intersection requiring evaluation of traffic efficiency of signal control efficiency, and the starting line of the detection range is superposed with an intersection stopping line, and the preset distance of the upstream of the stopping line is covered by the detection range. Cell phone data of all of cell phones in the detection range is acquired in a real-time manner, and comprises the ID numbers, the positions, and the moving speeds of the cell phones, and then the cell phone data of every cell phone is associated with the electronic map. The number of the cell phones stagnated in the detection range during red light time of each direction and the stagnated time of each cell phone are calculated accurately according to the cell phone data, and therefore the total stagnated time of the cell phones waiting for the red light is calculated, and is used as a total waiting time. Whether the intersection signal lamp control efficiency is ideal is evaluated according to a ratio between the red light waiting times of two directions, and the signal lamp efficiency is evaluated in a quantitative way.

Owner:北京博研智通科技有限公司

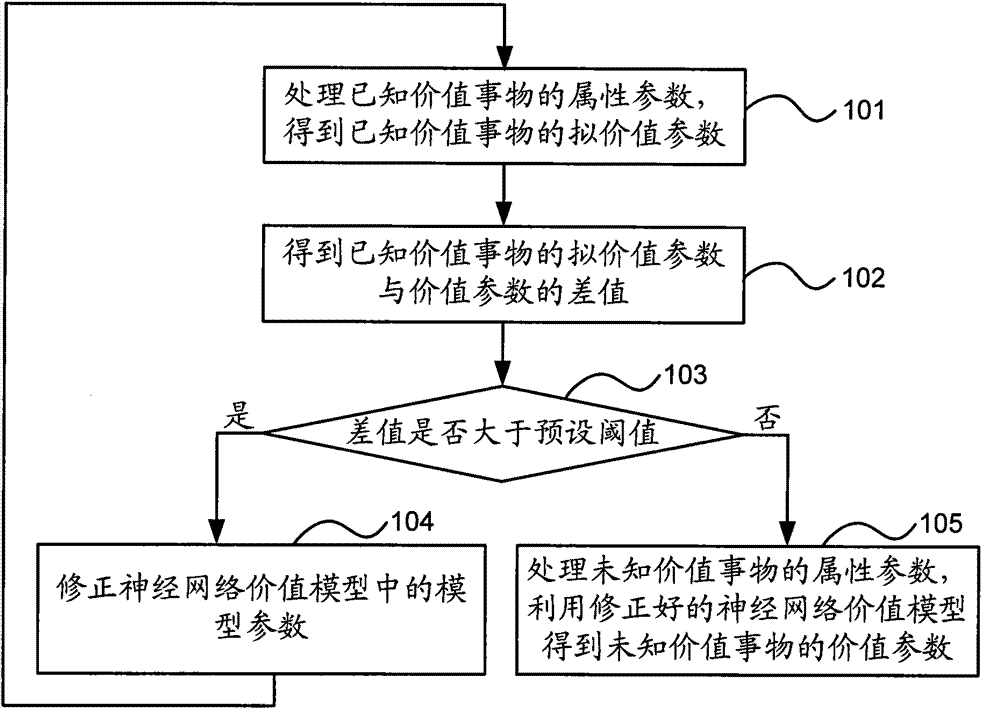

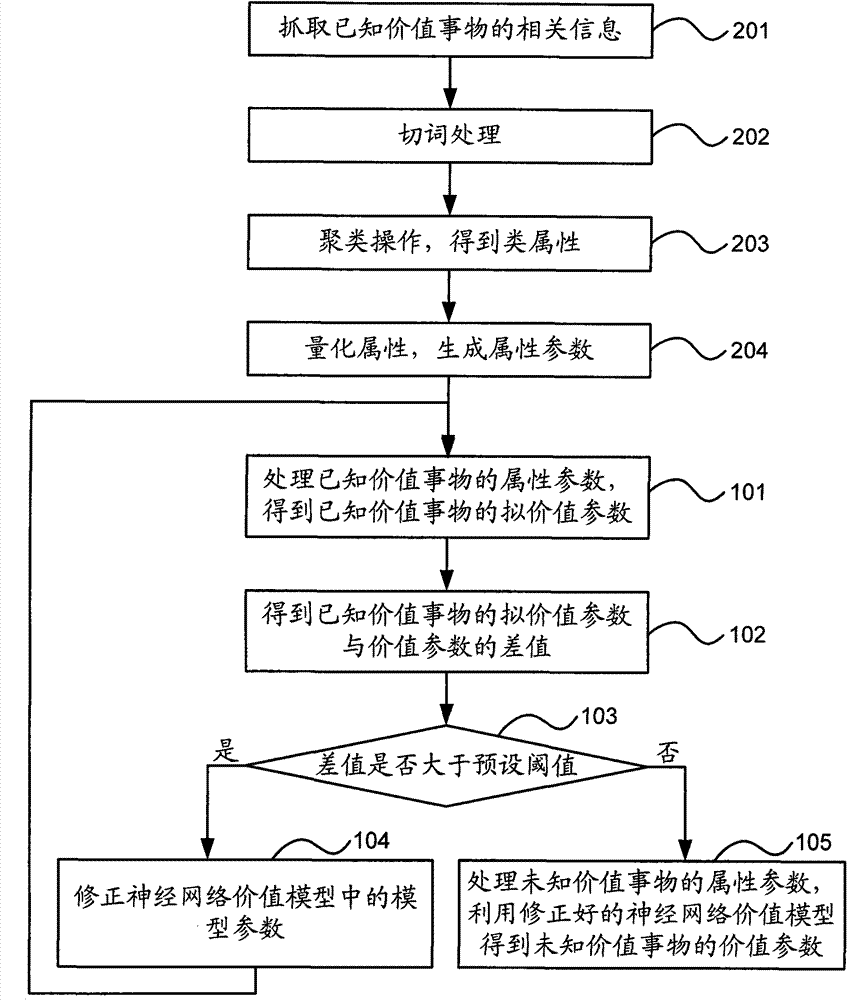

Information processing method based on internet

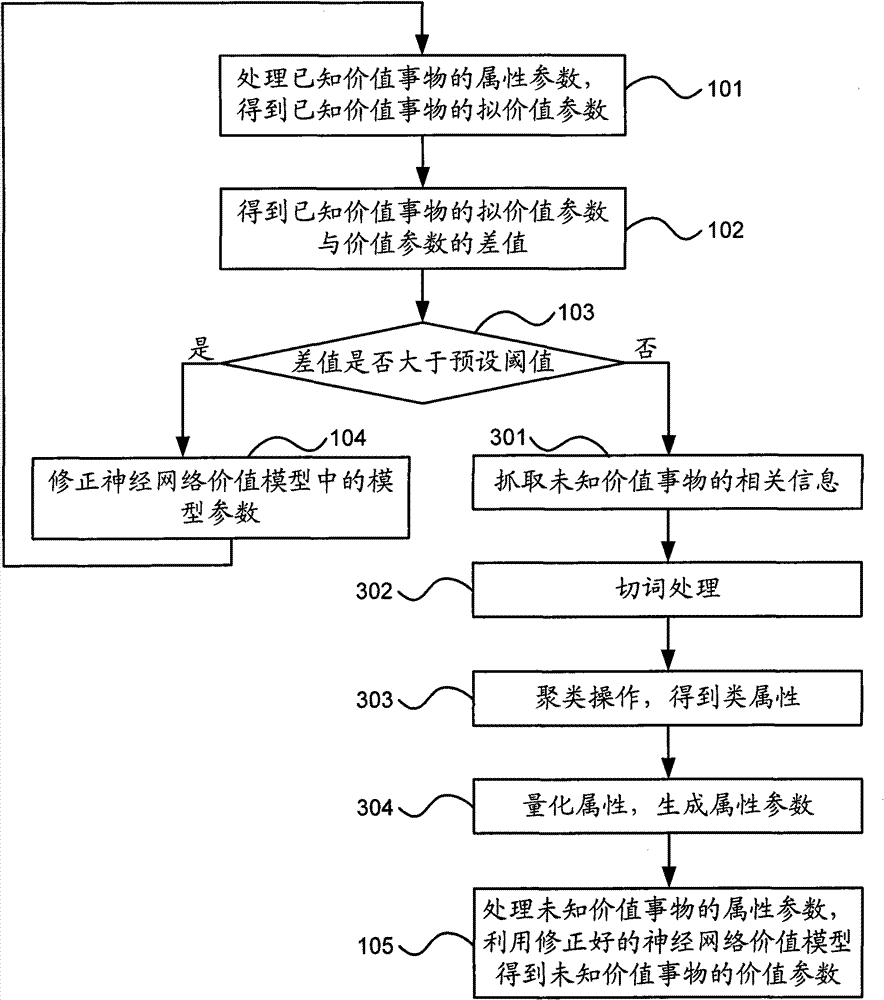

ActiveCN101789872BObjective evaluationComprehensive evaluationSpecial service provision for substationInformation processingThe Internet

The invention discloses an information processing method based on an internet, comprising the following steps of: processing the attribute parameters of a known value object by utilizing a neural network value model to obtain the virtual value parameter of the known value object; comparing the virtual value parameter with the value parameter of the known value object to obtain a difference; and comparing the difference with a preset threshold value, if the difference is greater than the preset threshold value, correcting model parameters in the neural network value model according to the difference and processing the attribute parameters of the known value object by utilizing the neural network value model; and if the difference is less than or equal to the preset threshold value, processing the attribute parameters of an unknown value object by utilizing the neural network value model. In the invention, corrects the model parameters in the neural network value model is corrected through utilizing the attribute parameters and the value parameters of the known value object to acquire the value parameters of the unknown value object, and objectively, comprehensively and quantitatively evaluate the values of objects.

Owner:蔡亮华

Automatic driving track evaluation method, device and equipment and storage medium

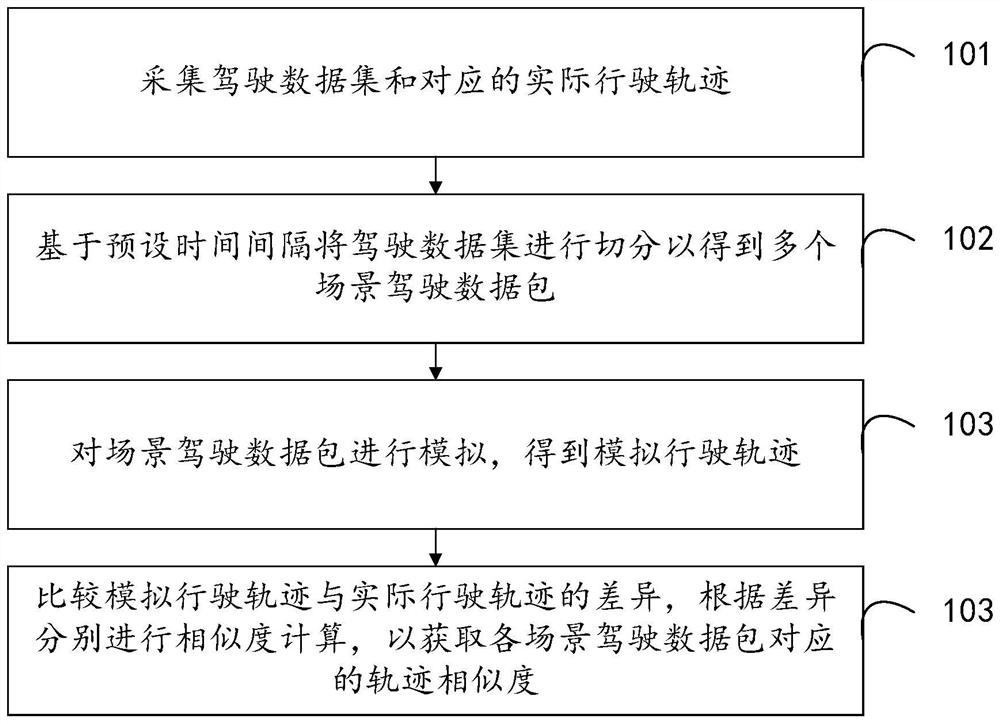

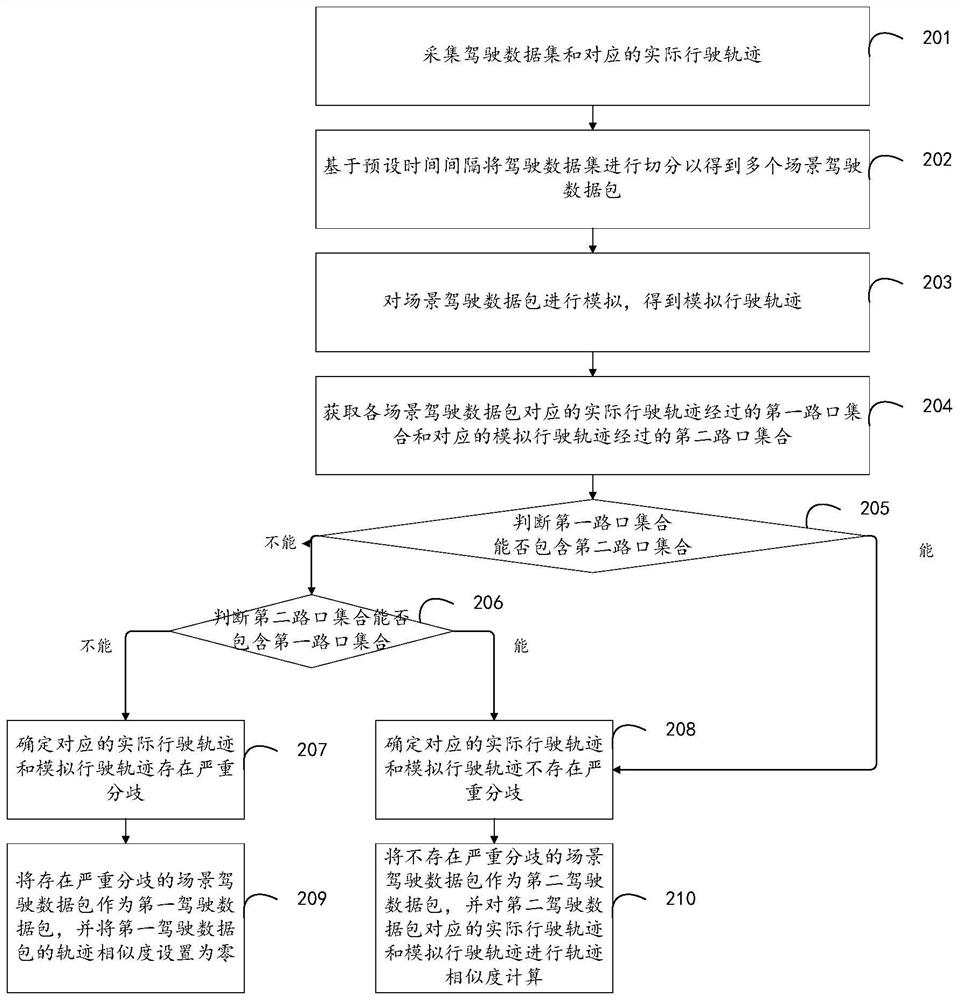

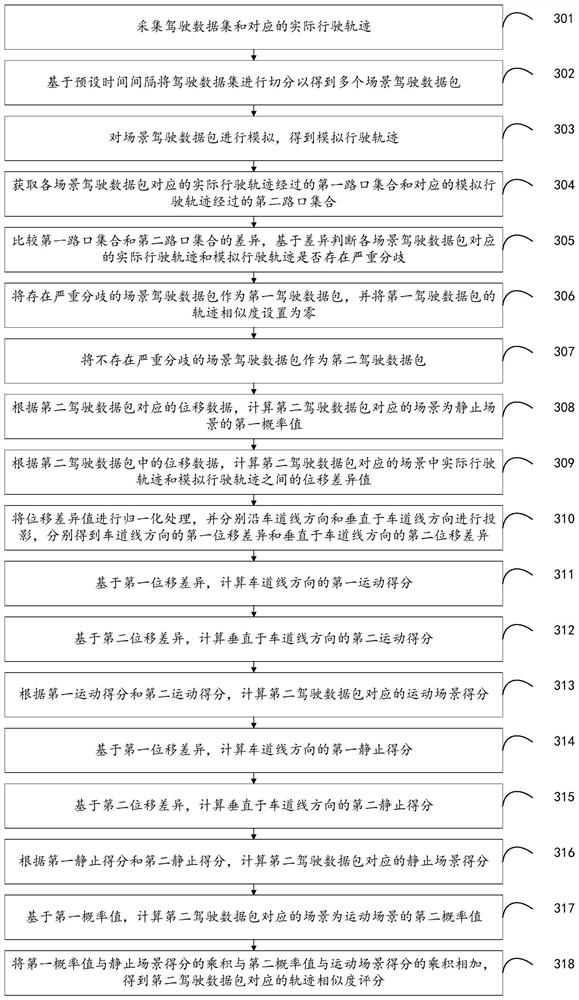

PendingCN113962110AQuantitative evaluationObjective evaluationCharacter and pattern recognitionDesign optimisation/simulationReal-time computingData pack

The invention relates to the field of automatic driving, and discloses an automatic driving track evaluation method, device and equipment and a storage medium, and the method comprises the steps: collecting a driving data set and a corresponding actual driving track; segmenting the driving data set based on a preset time interval to obtain a plurality of scene driving data packets; simulating the scene driving data packet to obtain a simulated driving track; and comparing the difference between the simulated driving track and the actual driving track, and performing similarity calculation according to the difference to obtain the track similarity corresponding to the driving data packet of each scene. According to the method, a large amount of human driving data is collected, then the data is played back in a simulation environment, an automatic driving system operates in the simulation environment, the difference between an automatic driving track and a human track is compared, a comprehensive score is given in combination with map information, the score can quantitatively, objectively and accurately evaluate the similarity between automatic driving and human drivers, and can be used for optimizing the output of an automatic driving algorithm.

Owner:GUANGZHOU WERIDE TECH LTD CO

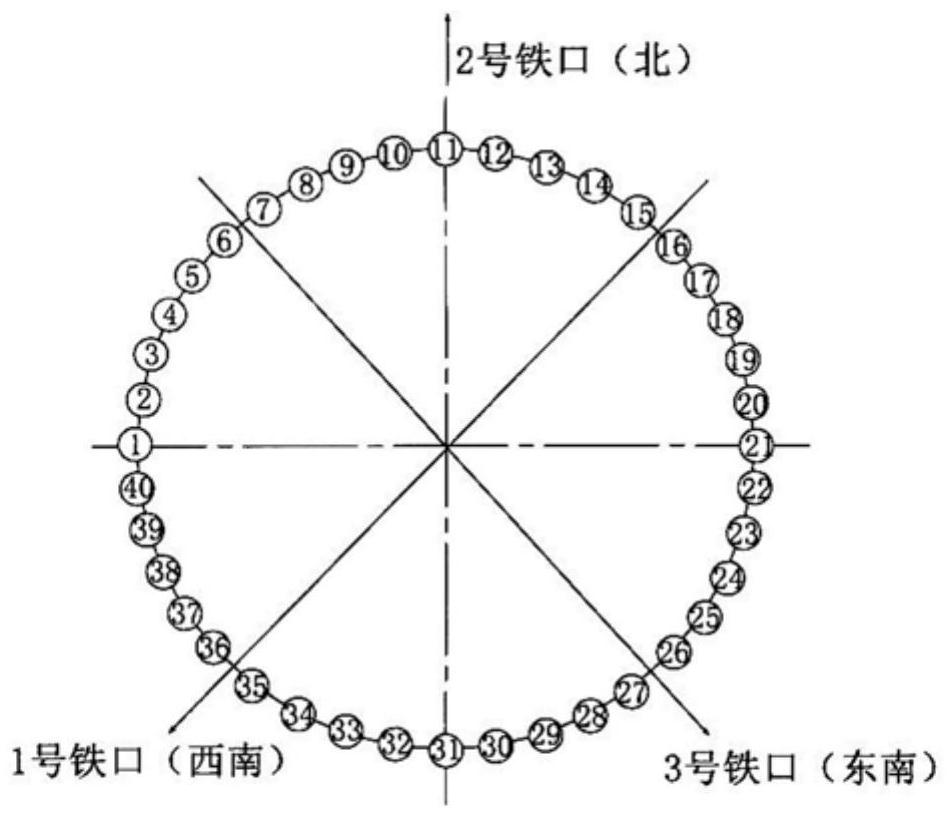

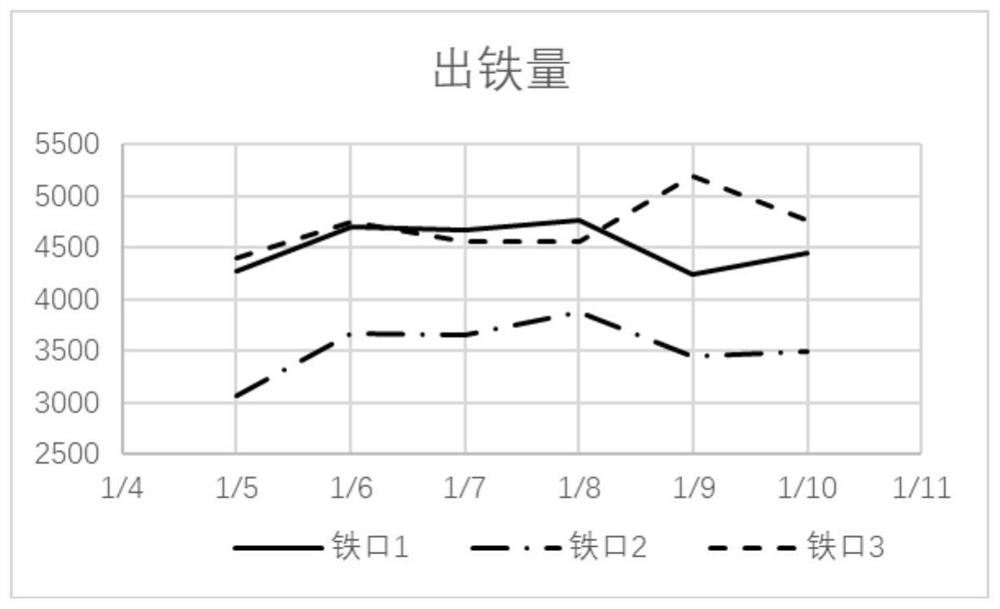

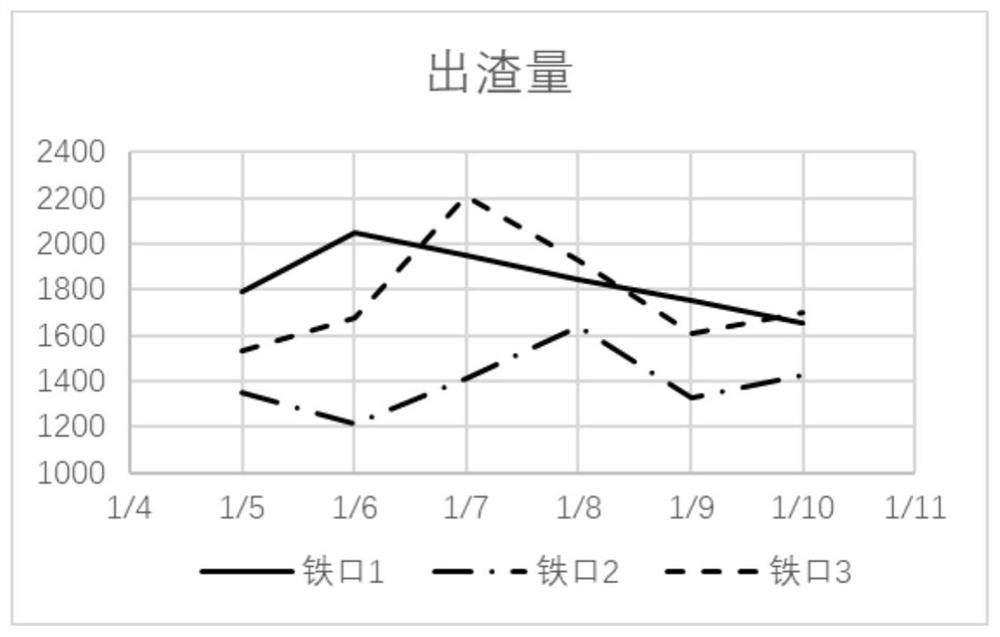

A Judgment Method for Uneven Working of Blast Furnace Hearth

ActiveCN113481337BQuantitative evaluationFast and Accurate EvaluationMeasurement devicesBlast furnace detailsSlagHearth

A method for judging the uneven operation of the hearth of a blast furnace, which collects the actual tapping and slag information of each furnace of molten iron in the blast furnace, and records the tapping times of the blast furnace, the actual amount of iron tapping, the actual amount of slag tapping, the tapping time, Slagging time, taphole depth, molten iron temperature, molten iron composition, and then calculate the iron flow rate and slag seeing rate at each tapping, and remove the data during the blast furnace ditch repair period to establish the daily slagging and iron tapping of each taphole of the blast furnace Information, according to the actual iron output, actual slag output, silicon content, molten iron temperature, iron flow speed and slag seeing rate conditions of the target iron hole, to judge whether there is uneven work in each iron hole of the blast furnace. The present invention is based on the slag discharge parameters of each tap hole during each tap, combined with the uniformity of air supply at the lower tuyeres and the setting of furnace top material distribution, diagnoses the uniformity of the hearth, and finds out the unevenness of the hearth The reason is to optimize the tapping system, air supply system and cloth system, which is fast and accurate.

Owner:SHAGANG GROUP +1

A Method for Evaluation of Substrate Surface Cleanliness Oriented to Structural Forming

ActiveCN112903709BQuantitative evaluationOptically investigating flaws/contaminationSurface cleaningEnvironmental engineering

The invention discloses a method for evaluating the surface cleanliness of a metal base material for construction and forming. According to the test results, the weight coefficients corresponding to oil stains, particles, and chips are set, and different methods are used to detect the pollution scores of different pollutants. Value, by calculating the product sum of all pollution weight coefficients and pollution scores, so as to quantitatively characterize its surface cleanliness. The invention proposes an accurate and systematic evaluation method of surface cleanliness for metal substrate construction and forming. Determine the weight coefficient of pollutants based on the degree of adverse effects of different pollutants on the healing of the substrate interface; adopt different detection methods for different pollutants, and determine the pollution scores of different pollutants; the weight coefficient of each pollutant The product and the pollution score are summed to determine the pollution value, and a comparison relationship is established to finally determine the cleanliness level, thereby accurately and quantitatively evaluating the surface cleanliness of the substrate.

Owner:DALIAN UNIV OF TECH

Detection method of grouting reinforcement effect in tunnel

InactiveCN101846604BQuick evaluationQuantitative evaluationMaterial strength using tensile/compressive forcesCore componentField data

The invention relates to a detection method and a detection device of grouting reinforcement effect in a tunnel, belonging to the field of tunnel engineering. The detection method of grouting reinforcement effect in the tunnel comprises the following steps: horizontally and respectively drilling the detection device into tunnel headings before and after grouting by using a drilling machine; forming an elliptical pilot tunnel in soil mass; inflating and pressurizing the measuring gas chamber of the device, and detecting the displacement of the short axis and the long axis of the elliptical pilot tunnel under the pressure at all levels; computing mechanical parameters (coefficient KO of earth pressure at rest, Poisson ratio mu and elastic modulus E) of the soil mass before and after grouting according to the elasticity theory formula; comparing the mechanical parameters of the soil mass before and after grouting; and making a conclusion of the grouting reinforcement effect according to the variation of the mechanical parameters of the soil mass before and after grouting. The core component of the detection device is the measuring gas chamber which is composed of a tubular expanded inner cavity and a rubber expanded film, and after the device is drilled into the soil mass, the displacement sensor and the pressure sensor of the measuring gas chamber are used for detecting field data. The invention has simple operation and can quickly, quantitatively and scientifically evaluate the grouting reinforcement effect.

Owner:BEIJING JIAOTONG UNIV

Casing pipe buckling evaluation method in inclined well cementing process

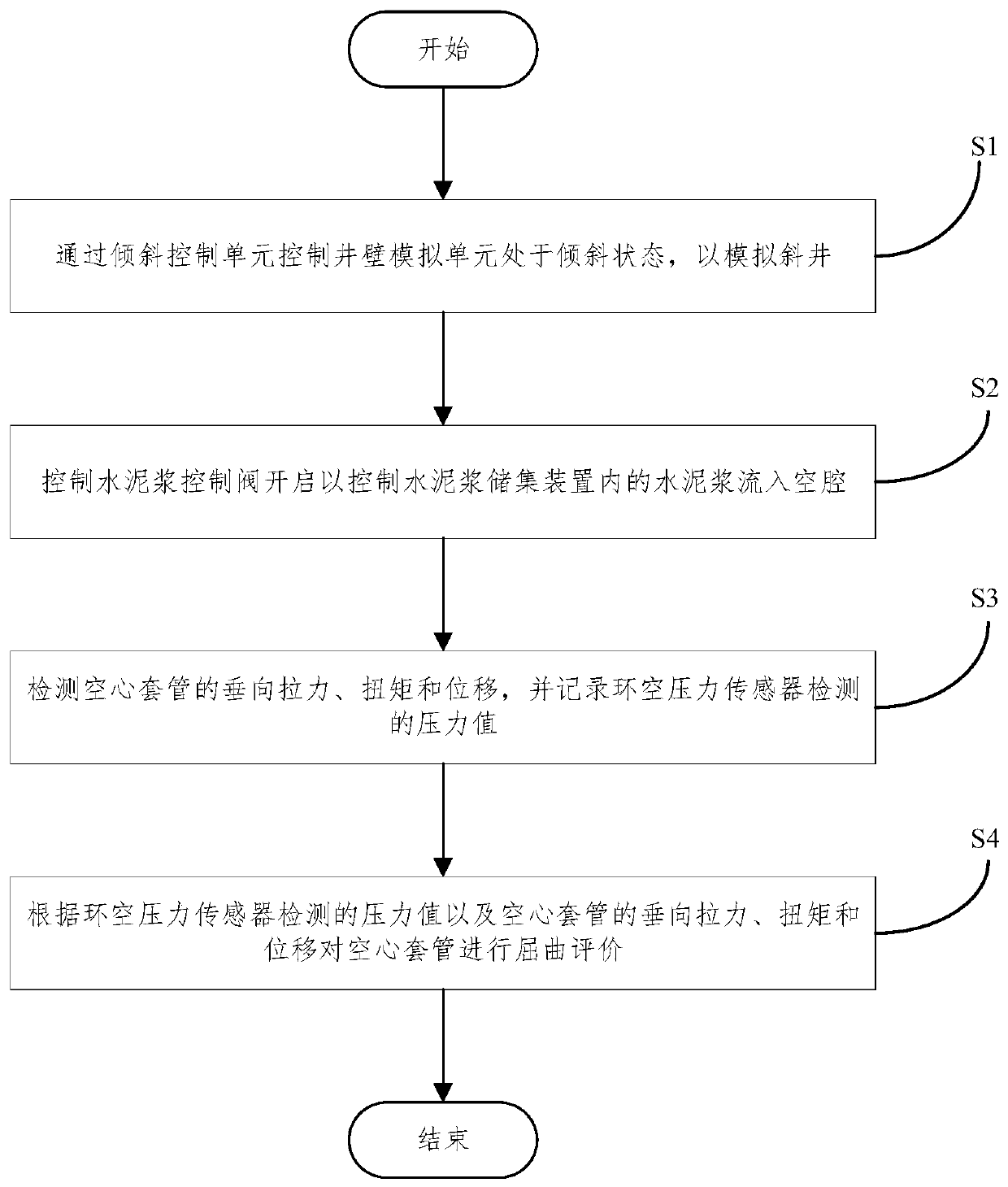

ActiveCN111426497AEase of evaluationQuick evaluationStructural/machines measurementControl cellWell cementing

The invention relates to a casing pipe buckling evaluation method in an inclined well cementing process. The method comprises the following steps of making a well wall simulation unit be in an inclined state through an inclination control unit so as to simulate an inclined well; making a cement paste control valve be opened to make cement paste in a cement paste storage and collection device flowinto a cavity; detecting a vertical tension, a torque and displacement of a hollow casing pipe, and recording a pressure value detected by an annulus pressure sensor; performing buckling evaluation onthe hollow casing pipe according to the pressure value detected by the annulus pressure sensor and the vertical tension, the torque and the displacement of the hollow casing pipe; and by analyzing astress change process of the hollow casing pipe, realizing monitoring and evaluation of the buckling of the hollow casing pipe. The method is easy to implement, convenient to operate and good in feasibility, the influence of cement paste buoyancy on a stress change of the hollow casing pipe in the inclined well cementing process can be simply, conveniently, quickly and quantitatively evaluated, and a purpose of evaluating the buckling of the casing pipe is achieved.

Owner:XINJIANG ZHENGTONG OIL & GAS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com