Construction-forming-oriented substrate surface cleanliness evaluation method

A technology of substrate surface and evaluation method, applied in the direction of analyzing materials, material analysis by optical means, optical testing of flaws/defects, etc., can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

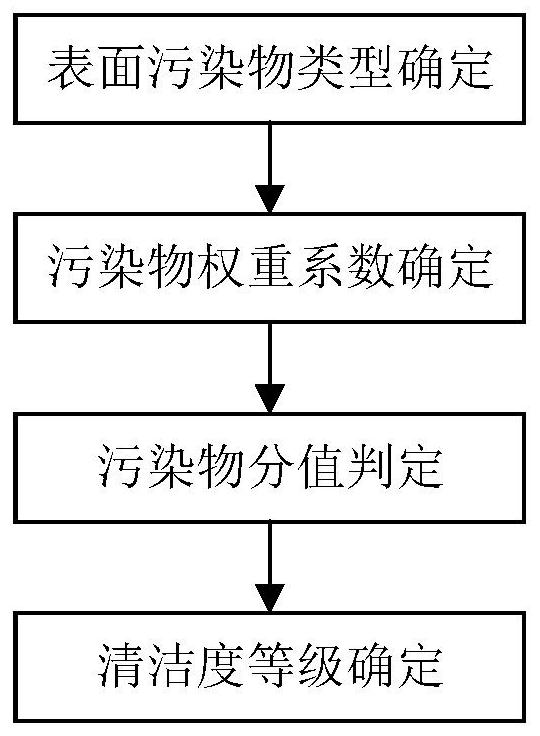

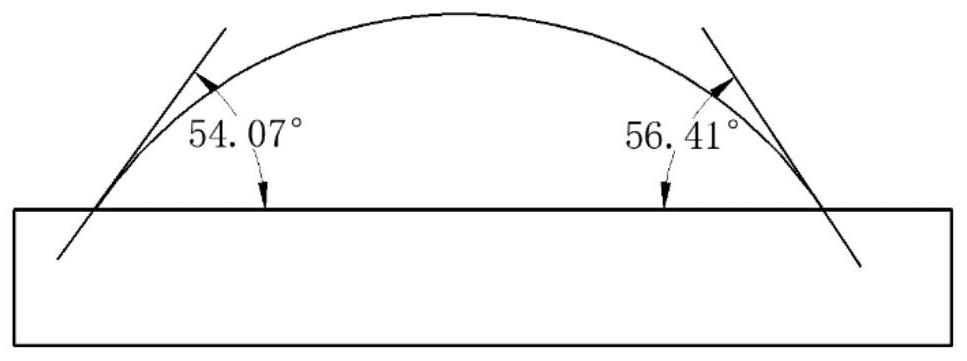

[0039] The steps of using the present invention to evaluate the surface cleanliness of the small sample after simply purging with an air gun after milling are as follows:

[0040] 1) Select different areas, use the X-ray energy spectrum analyzer to detect the composition of the surface of the small sample part by surface scanning, combined with the observation of the ultra-depth microscope, determine the types of surface pollutants according to the composition and appearance characteristics as oil, particles, swarf.

[0041]2) Starting from the healing performance of the substrate interface formed by the construction of the metal substrate, evaluate the degree of hindrance to the healing of the substrate interface by oil, particles, and chips, and determine the weight coefficient WC corresponding to the pollutants according to the degree of hindrance to the substrate interface healing i , where the weight coefficients of oil, particles, and chips are expressed as: WC 1 , WC ...

Embodiment 2

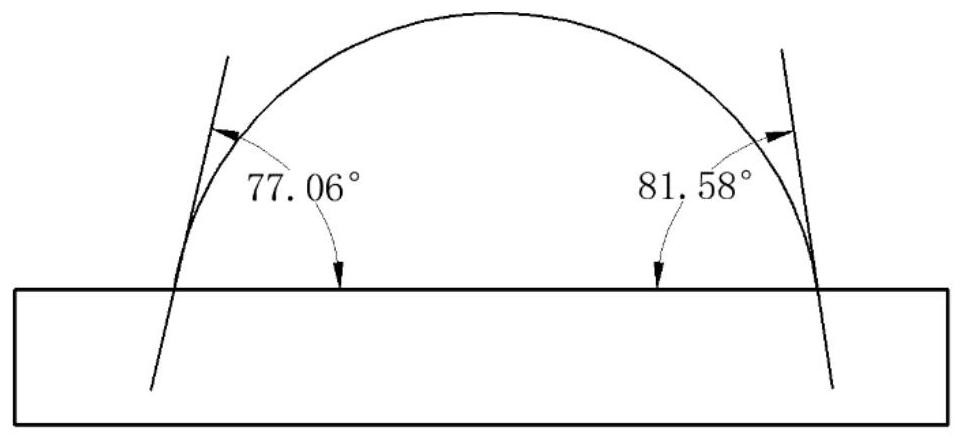

[0045] The steps of using the present invention to evaluate the surface cleanliness of the small sample after purging with an air gun and ultrasonic cleaning for 15min after milling are as follows:

[0046] 1) Select different areas, use the X-ray energy spectrum analyzer to detect the composition of the surface of the small sample part by surface scanning, combined with the observation of the super depth of field microscope, determine the type of surface pollutants according to the composition and appearance characteristics, only particle pollutants remain .

[0047] 2) Starting from the healing performance of the substrate interface formed by the construction of the metal substrate, evaluate the degree of hindrance to the healing of the substrate interface by oil, particles, and chips, and determine the weight coefficient WC corresponding to the pollutants according to the degree of hindrance to the substrate interface healing i , where the weight coefficients of oil, partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com