A Judgment Method for Uneven Working of Blast Furnace Hearth

A blast furnace furnace and working technology, which is applied in the field of judging the uneven work of the blast furnace hearth, can solve the problems of large corrosion of refractory materials and lagging reflection of working status, etc., and achieve economic benefits, optimization of air supply system and material distribution system, Effect of reducing delay in processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

Embodiment 2

Embodiment 3

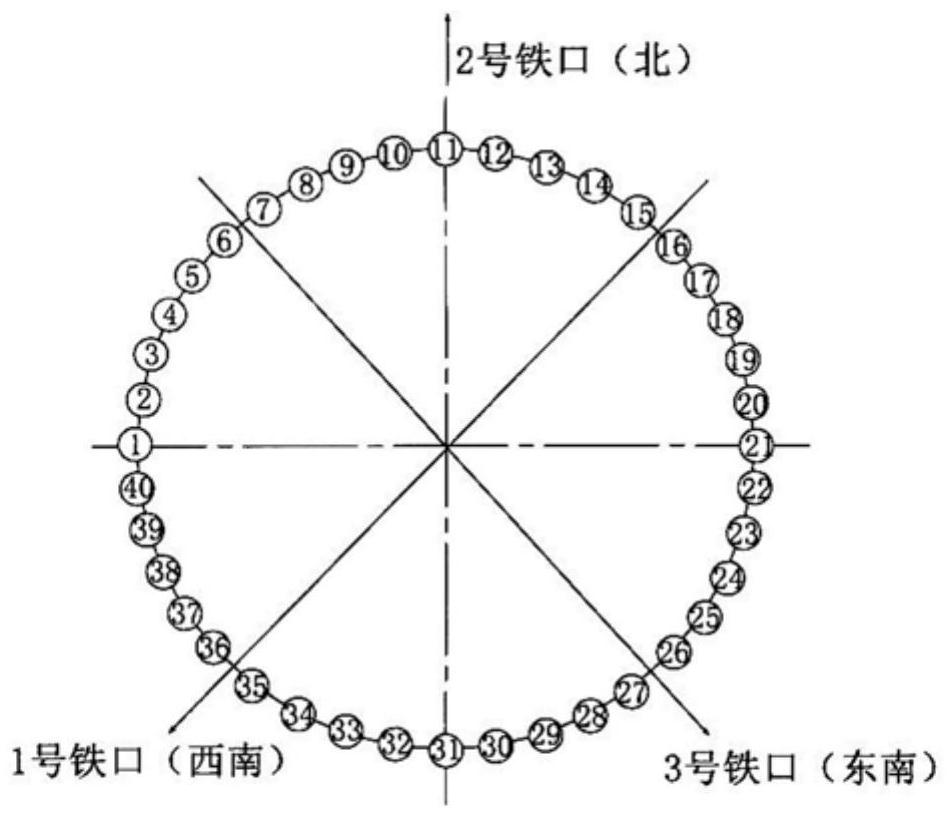

[0060] The volume of a certain 5800 blast furnace of Jiangsu Shagang Group Co., Ltd. is 5800 m³, and there are 3 tapholes, and the 3 tapholes are continuous

[0062]

[0064]

[0066]

[0073] a), b), c), d), e) and f) are satisfied at the same time, then there is uneven work in each taphole of the blast furnace. This shows that in

[0074] In the target time period, when a certain iron hole of the blast furnace has a situation of uneven operation, repair is performed. specific

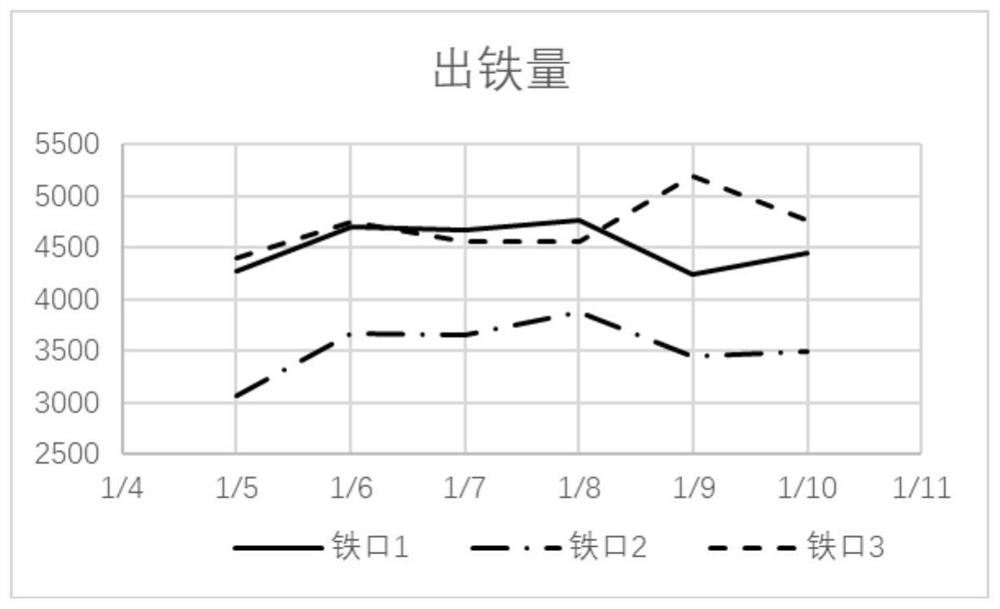

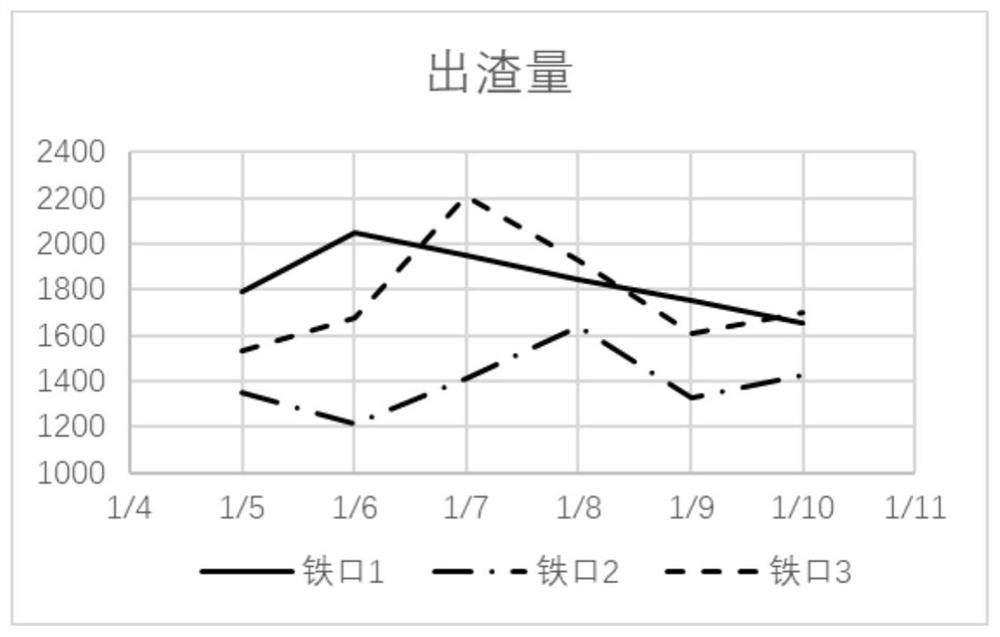

[0075] During the period from January 5 to 10, 2020, referring to Figure 8, the depth of the iron mouth of the 2# iron mouth has always been shallow (Figure 8), and it is possible to pass

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com