Method for evaluating temperature uniformity of hot rolled strip steel in width direction

A technology of hot-rolled strip steel and uniformity, applied in the field of hot-rolled strip steel, which can solve the problems of heavy workload and low objectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

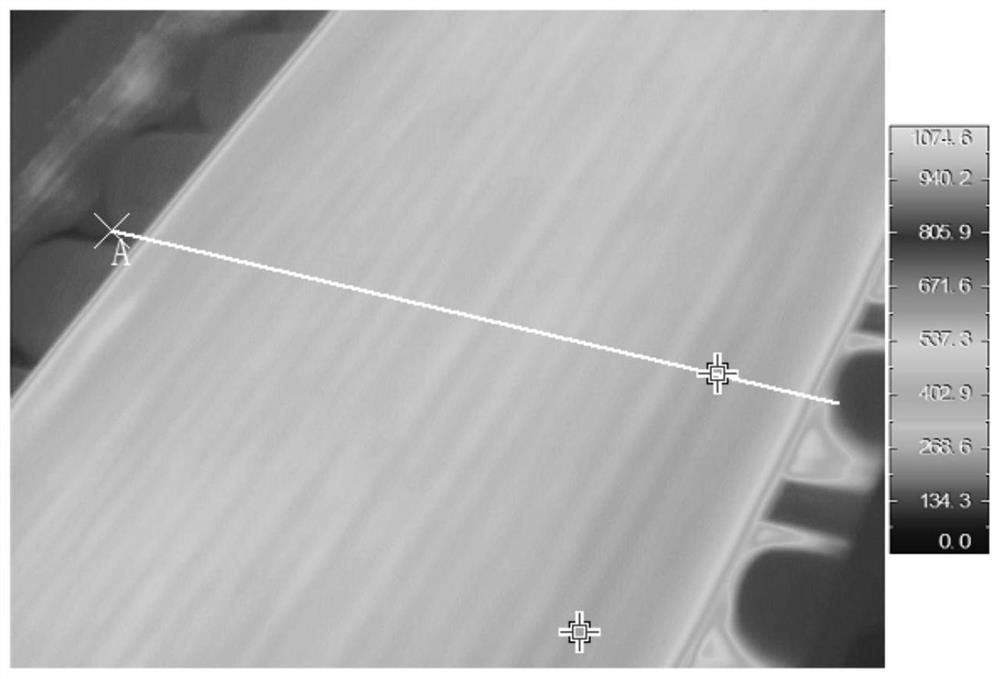

[0036] A method for evaluating temperature uniformity in the width direction of hot-rolled steel strip in this embodiment, such as image 3 shown, including the following steps:

[0037] Step 1. Add a temperature measuring line and generate the temperature data of the temperature measuring line;

[0038] Step 2. Data processing to determine the position of the edge of the strip: the conduction rate of heat conduction in the air is obviously different from that in the strip, so there will be an obvious turning point in the temperature data value derived from line A. The temperature at the previous position is subtracted from the temperature at the previous position to determine the change of temperature, and the point with the largest temperature turning point is the edge position of the strip;

[0039] Step 3, the relative coordinates are converted into the absolute position points of the strip width;

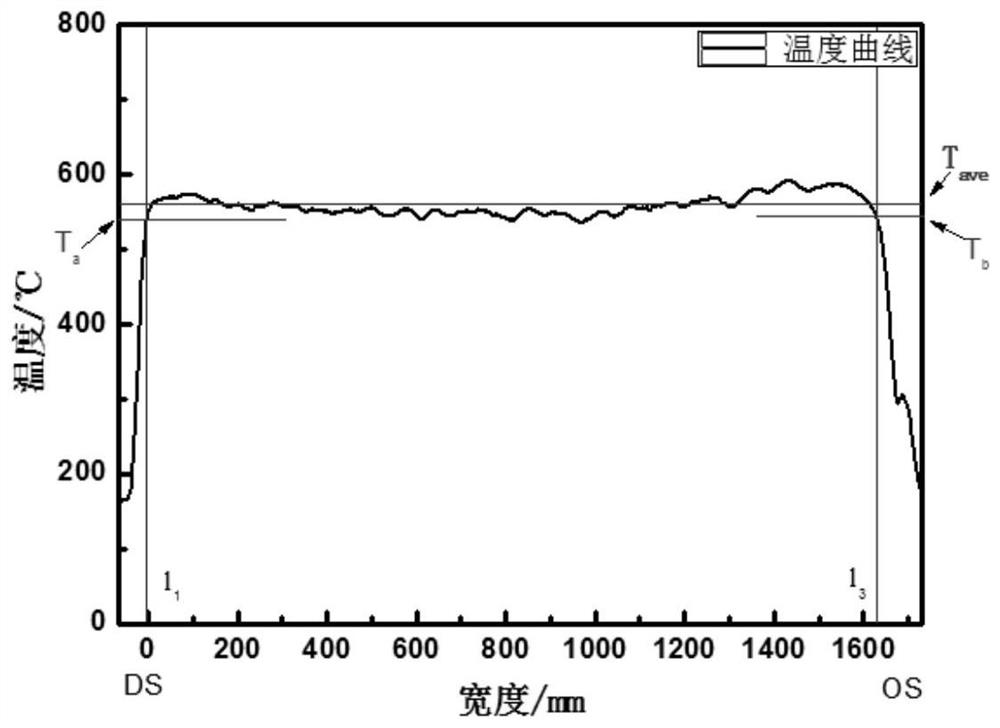

[0040] Step 4. Determine the average temperature T in the width directio...

Embodiment 2

[0049] A method for evaluating temperature uniformity in the width direction of hot-rolled strip steel in this embodiment, the basic structure is the same as that in Embodiment 1, the difference and improvement are: it also includes calculating the edge temperature drop on the operating side and the transmission side of the hot-rolled strip steel value, the operating side temperature drop is: △T 操作 =T ave -T a , the transmission side temperature drop is: △T 传动 =T ave -T b , to simply and objectively calculate the temperature drop values of the operating side and the driving side in the width direction of the hot-rolled strip, and finally quantitatively evaluate the temperature uniformity of the hot-rolled strip.

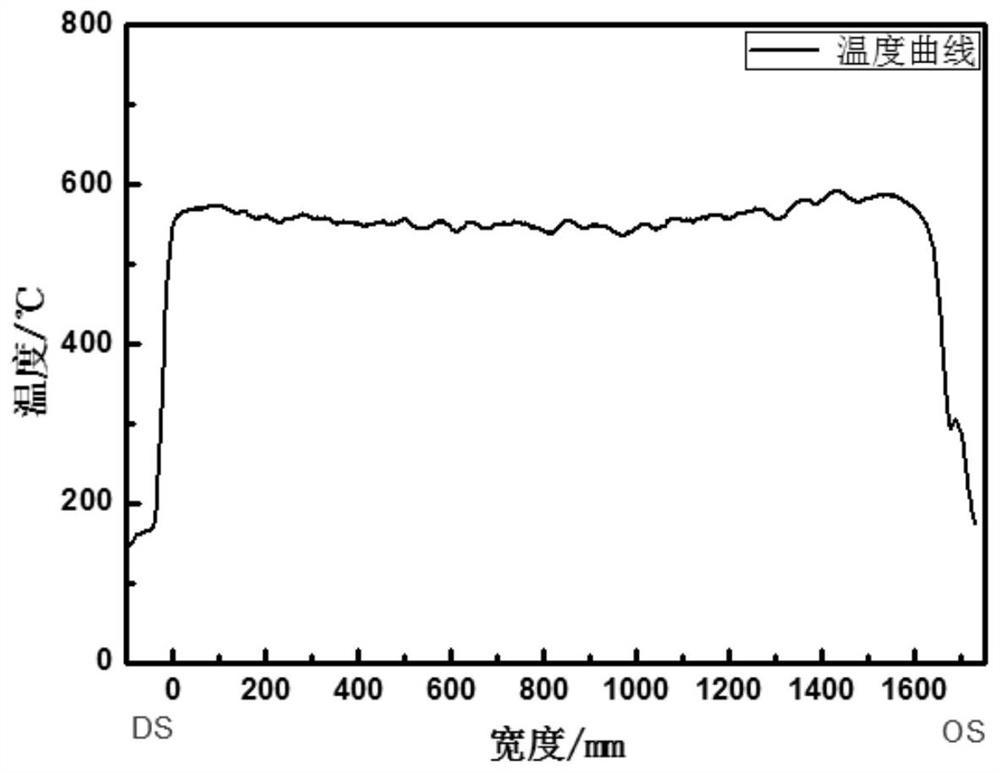

[0050] In this embodiment, taking the 8×1625mm hot-rolled steel strip produced by a steel factory as an example, the temperature data of the hot-rolled strip after laminar cooling is measured, and the calculated temperature data is Figure 4 shown. Depend on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com