Real-time monitoring device and method for cold spraying coating and interface defects of cold spraying coating

A technology for interface defect, real-time monitoring, applied in measurement devices, comprehensive factory control, instruments, etc., can solve problems such as loss of life and property safety, strength failure, threats, etc., to achieve the effect of environmental protection, convenient operation, and work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

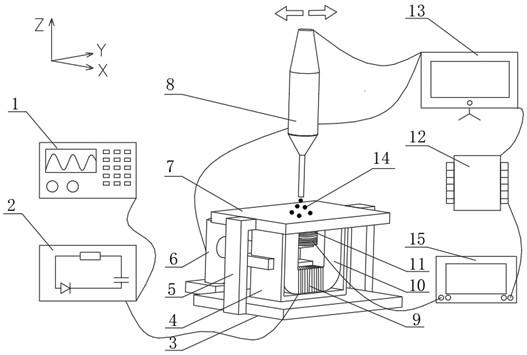

[0037] as Figure 1 Schematic diagram of a real-time monitoring device for cold spray coating and interface defects of the present invention, the real-time monitoring device for cold spray coating and interface defects thereof comprises: a signal generation module, a magnetic field excitation module, a motion control module, a data acquisition module and a fixed module of the apparatus, a signal generation module comprising a signal generator 1 and a power amplifier 2, for generating a periodic electrical signal, and the electrical signal is amplified and transmitted to the magnetic field excitation module; the magnetic field excitation module comprises a U-shaped yoke 10, an excitation coil 9 and a signal receiver 11, To be sprayed ferromagnetic material 7 to provide a continuously varying periodic applied excitation magnetic field; the motion control module is mainly composed of a robotic arm 6 and a cold spraying device 8, for controlling the magnetic field excitation module and...

Embodiment 2

[0049] The cold spray coating and the interface defect real-time monitoring apparatus of the present invention adjusts the electrical signal frequency of different sizes through the signal generation module, the magnetic field excitation module magnetizes different thickness substrates and coatings and outputs the magnetic Barkhausen electrical signal, and drives the synchronous motion of the magnetic field excitation module and the cold spraying device 8 by the host computer 13, the collected signal is fed into the host computer 13, the data is analyzed and different feature values are extracted, and the internal defects of the ferromagnetic material and the cold spray coating of different thicknesses are monitored in real time. Therefore, based on magnetic Barkhausen detection technology, the present invention provides a real-time monitoring method for cold spray coatings and interfacial defects thereof, comprising the following steps:

[0050] Step 1: The ferromagnetic material t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com