Compression type refrigerating and heating outdoor heat exchange device

A technology of compression refrigeration and outdoor heat exchange, which is applied in the direction of refrigerators, compressors, refrigeration components, etc., and can solve the problem of decreasing the heat transfer efficiency of finned surface heat exchangers and increasing the heat transfer of finned surface heat exchangers Thermal resistance, unit energy efficiency reduction and other issues, to achieve the effect of improving heating efficiency, simple structure, and improving energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: during refrigeration:

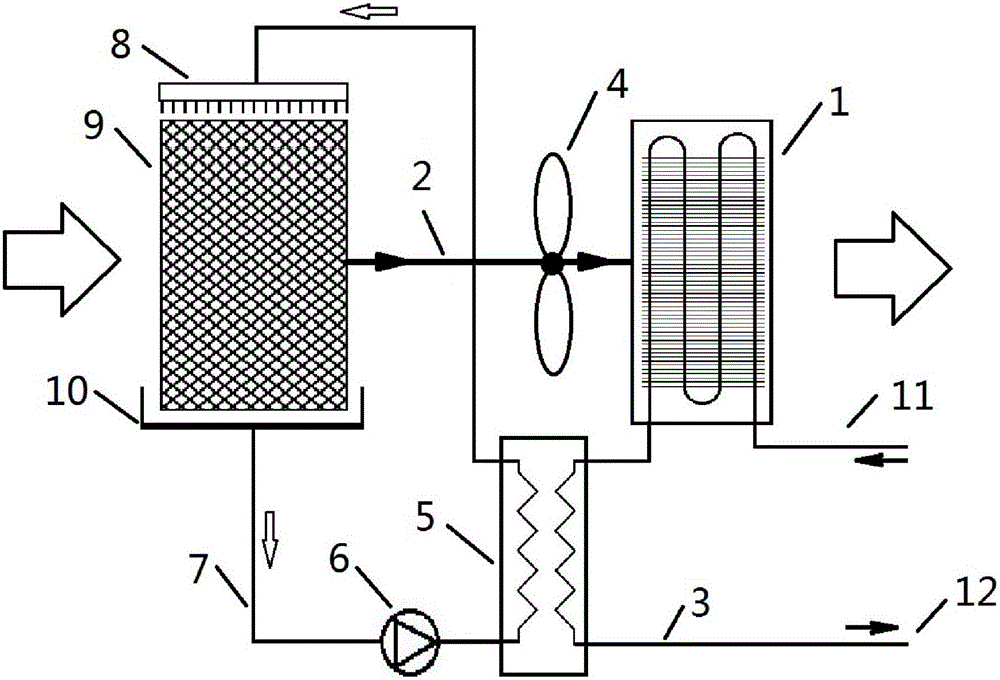

[0025] The high-temperature and high-pressure gaseous refrigerant passes through the refrigerant circulation pipeline 3 and flows into the finned surface heat exchanger 1 to condense through the refrigerant pipeline inlet 11, and then flows into the water-refrigerant heat exchanger 5 through the refrigerant circulation pipeline 3 to be cooled into a completely liquid refrigerant, and then passes through the refrigerant pipeline Outlet 12 flows out.

[0026] Powered by the circulating water pump 6, the low-temperature water is first sent to the water-refrigerant heat exchanger 5 to exchange heat with the refrigerant through the circulating water pipeline 7, and the water that absorbs the heat of the refrigerant is then sent to the water distributor 8 through the circulating water pipeline 7 for even spraying. The evaporative heat and moisture exchanger 9, water flows evenly from top to bottom from the surface of the evaporative heat ...

Embodiment 2

[0028] Embodiment 2: when heating:

[0029] The low-temperature and low-pressure liquid refrigerant flows into the finned surface heat exchanger 1 to evaporate through the refrigerant circulation pipe 3 through the refrigerant pipe inlet 11, and then flows into the water-refrigerant heat exchanger 5 through the refrigerant circulation pipe 3 to evaporate into a completely gaseous refrigerant and then passes through the refrigerant pipe Outflow from exit 12;

[0030] Powered by the circulating water pump 6, the relatively high-temperature water is first sent to the water-refrigerant heat exchanger 5 to exchange heat with the refrigerant through the circulating water pipeline 7, and the water absorbed by the refrigerant is then sent to the water distributor 8 through the circulating water pipeline 7 for uniformity Spray to the evaporative heat and moisture exchanger 9, and the water flows evenly from top to bottom from the surface of the evaporative heat and moisture exchanger 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com