Wet sludge treatment method and equipment thereof

A technology for processing equipment and wet sludge, applied in dehydration/drying/concentrated sludge treatment, deodorization, disinfection, etc., can solve problems such as immature technology and equipment, poor environmental sanitation, and low reliability, and achieve volatilization Less flammable gas, energy saving, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

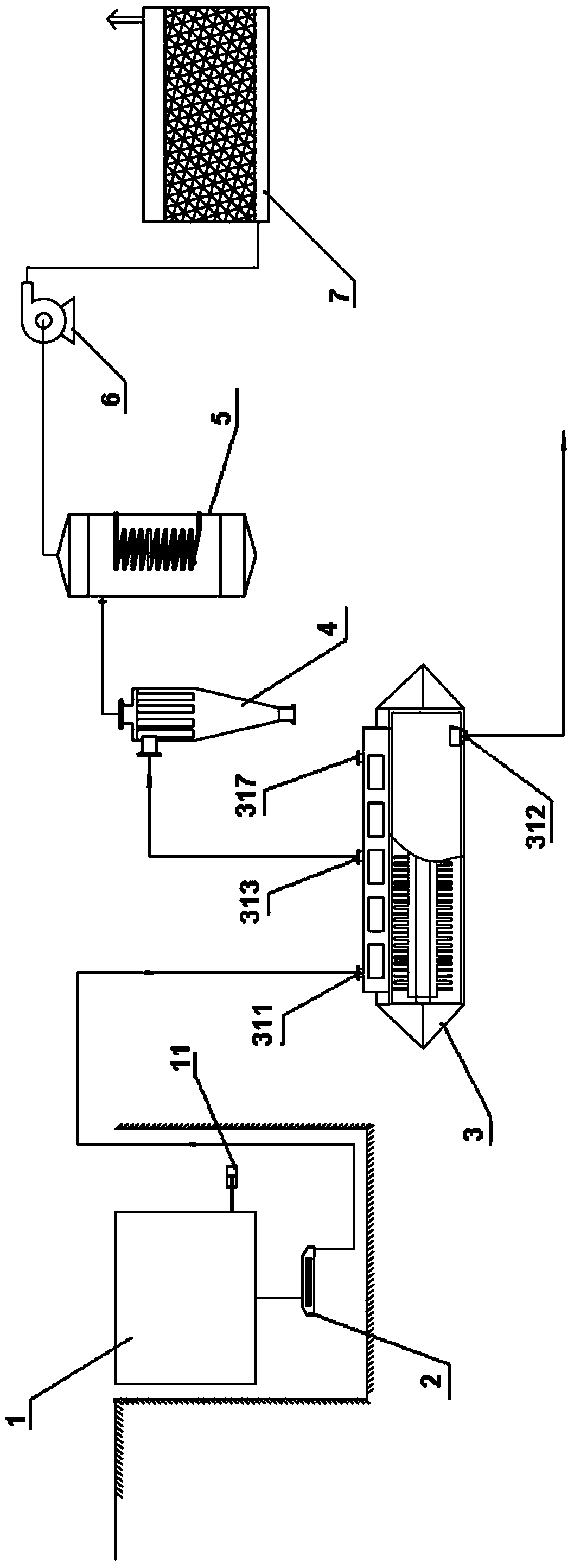

[0058] Example 1 Wet sludge treatment equipment

[0059] A wet sludge treatment equipment, including a wet sludge silo 1 and at least one set of treatment equipment (for example, 2 or 3 sets), wherein the treatment equipment includes a wet sludge delivery pump 2, sludge drying and forming equipment 3. Dust collector 4, condenser 5, induced draft fan 6 and deodorizing device 7;

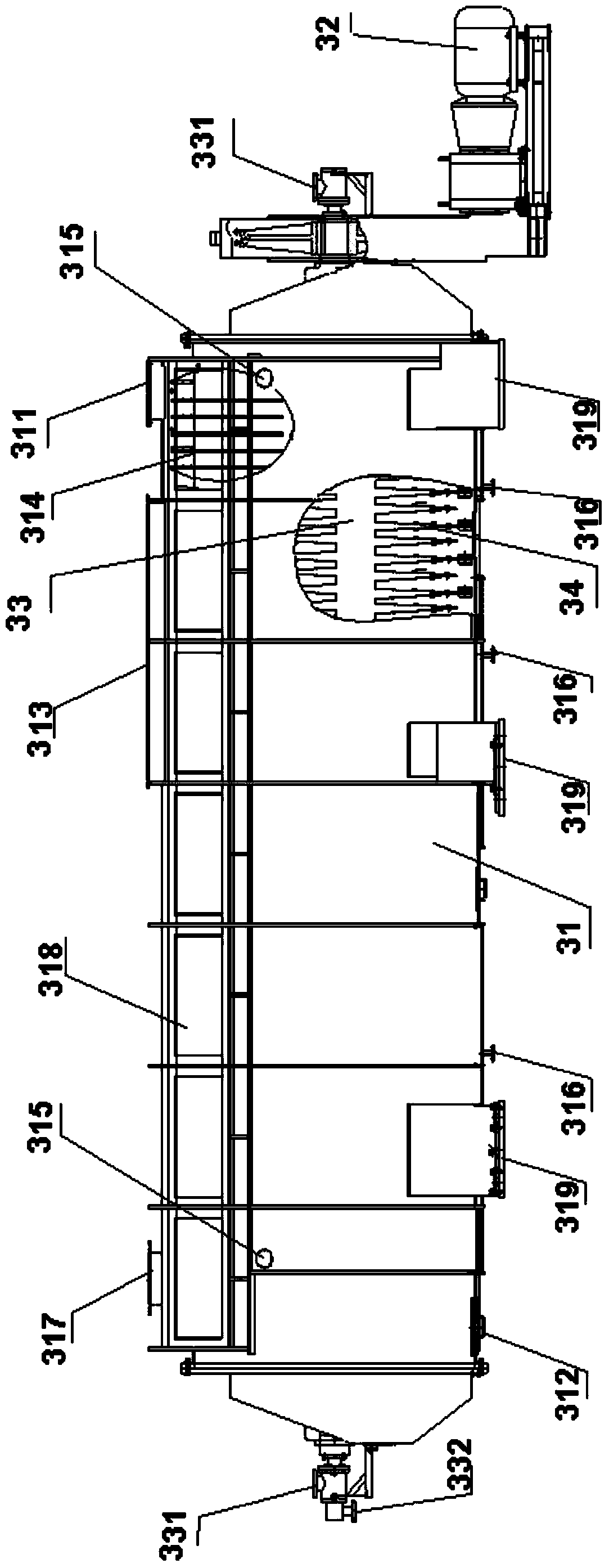

[0060] Wherein, the sludge drying molding equipment 3 is a disc type sludge drying molding equipment, including a housing 31, a main shaft system and a driving transmission device 32; wherein, the main shaft system is located in the housing 31; the driving transmission device 32 is installed At one end of the main shaft system; the housing 31 is provided with a material inlet 311, a material outlet 312 and an exhaust gas outlet 313;

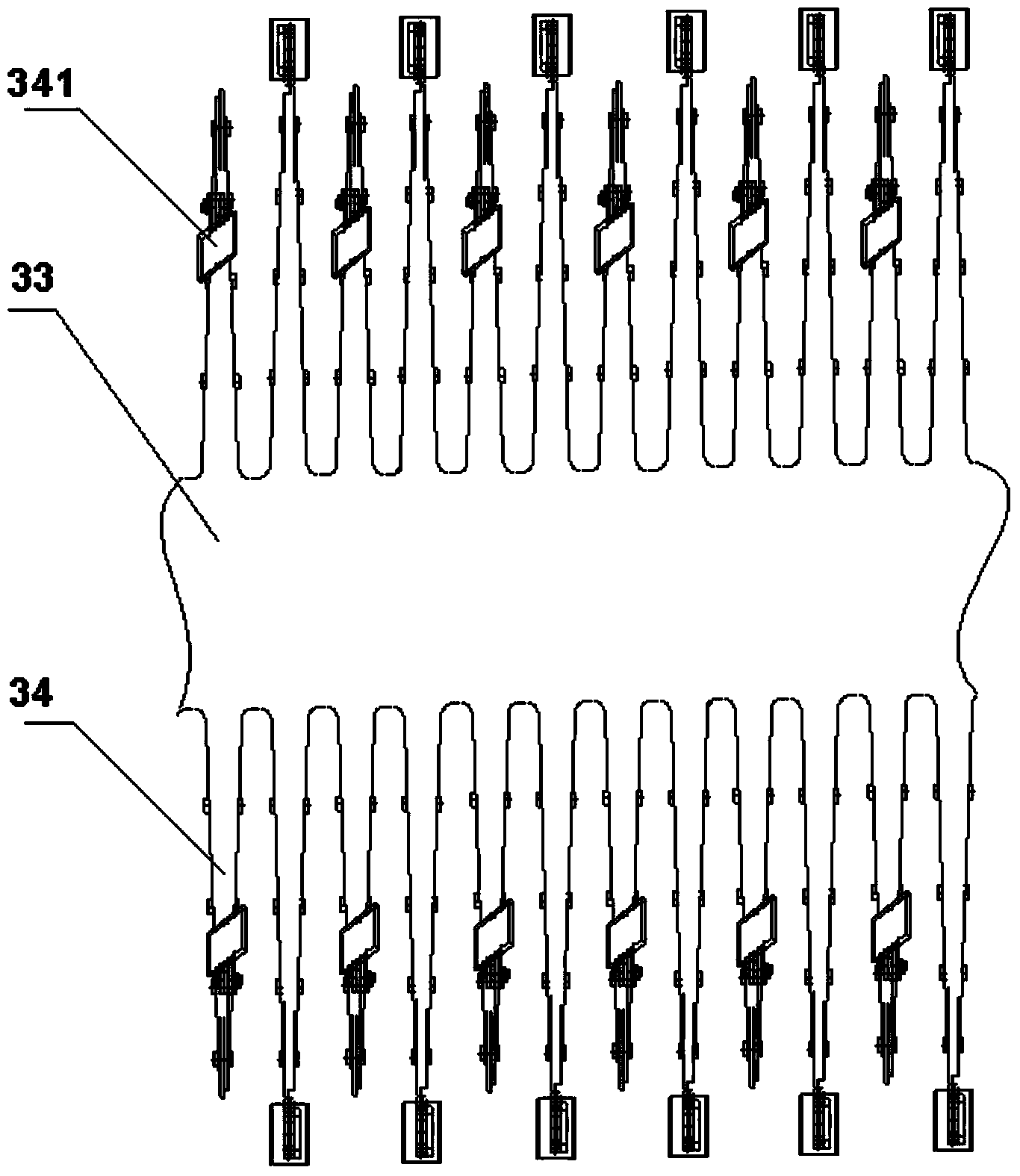

[0061] The spindle system includes a hollow shaft 33 and a plurality of discs 34 ; wherein, two ends of the hollow shaft 33 are provided with a steam inlet 331 , and one e...

Embodiment 2

[0078] Example 2 Treatment of wet sludge 300 tons / day

[0079] 300 tons / day of municipal sludge in a certain town is centrally disposed, and the system is equipped with 3 sets of treatment devices. The moisture content of the wet sludge is 80-85%. It is transported to the centralized sludge disposal plant by vehicle, and temporarily stored in the sludge silo. The carriage in the sludge silo reciprocates to squeeze the sludge into the sludge delivery pump. , transported to the disc-type drying equipment through pressure pipes, and the cutting sludge is stirred by the inner feathers and scrapers of the drying equipment, and after staying for 1-2 hours, it is dried into dry sludge with a moisture content of 35-40%. The diameter of mud particles is 3-5mm, which is transported to incineration or other final disposal through conveying equipment. The tail gas produced by drying contains a small amount of dust. The dust is regularly removed in the bag filter and electric heating is u...

Embodiment 3

[0080] Example 3 Treatment of wet sludge 200 tons / day

[0081] Centralized disposal of 200 tons / day of municipal sludge in a certain town is carried out in a waste incineration power plant. The low-quality steam in the power plant is used to dry the sludge, and the system is equipped with 2 sets of treatment devices. The moisture content of the wet sludge is 80-85%. It is transported to the garbage power plant by vehicle and stored temporarily in the sludge silo. The carriage in the sludge silo reciprocates to squeeze the sludge into the sludge delivery pump. The pressure pipeline is used to transport the sludge to the disc drying equipment, and the cutting sludge is stirred by the inner feathers and the mud cutter of the drying equipment. After staying for 1-2 hours, it is dried into dry sludge with a moisture content of 35-40%. The diameter of mud particles is 3-5mm, which is transported to incineration or other final disposal through conveying equipment. The tail gas prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com