Ladder-shaped internal threaded hole processing method of steam turbine outer ring part

An internal thread hole and processing method technology, applied in metal processing equipment, tangent machines, manufacturing tools, etc., can solve the problems of low processing efficiency, complex processing, and easily damaged arc surfaces, and achieve high processing efficiency, easy processing, Efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

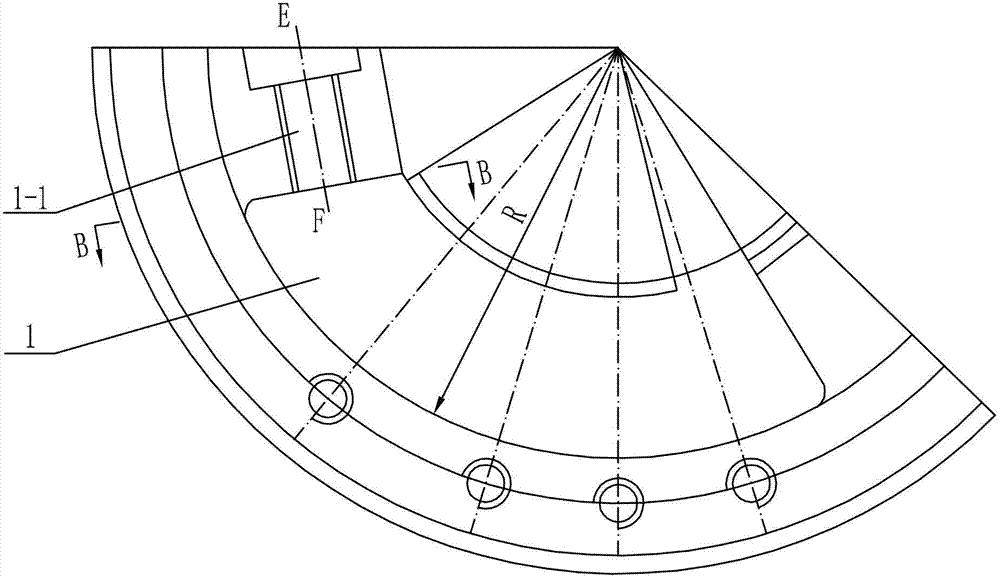

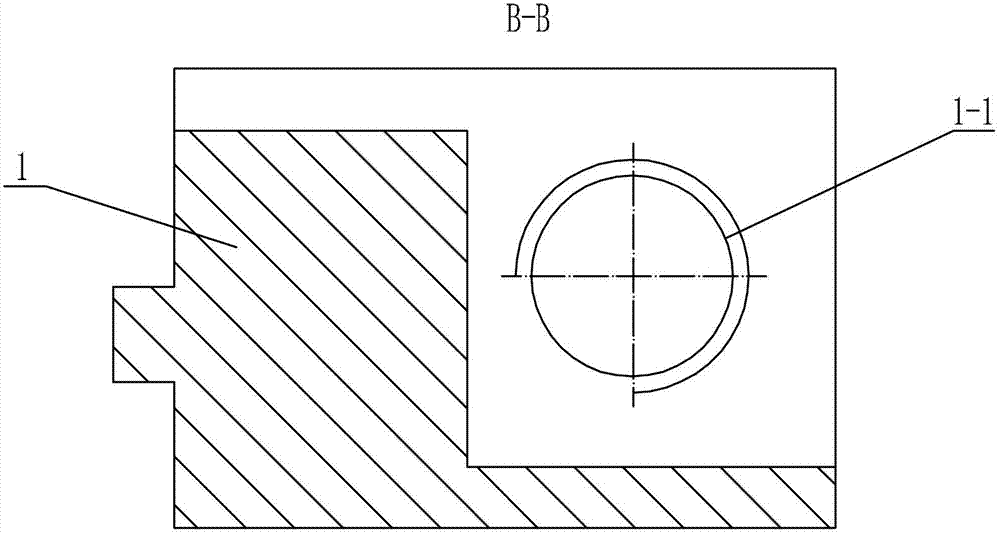

[0011] Specific implementation mode one: combine Figure 1-Figure 6 Describe this embodiment, the concrete steps of a kind of steam turbine outer ring part trapezoidal internal thread hole processing method of this embodiment are:

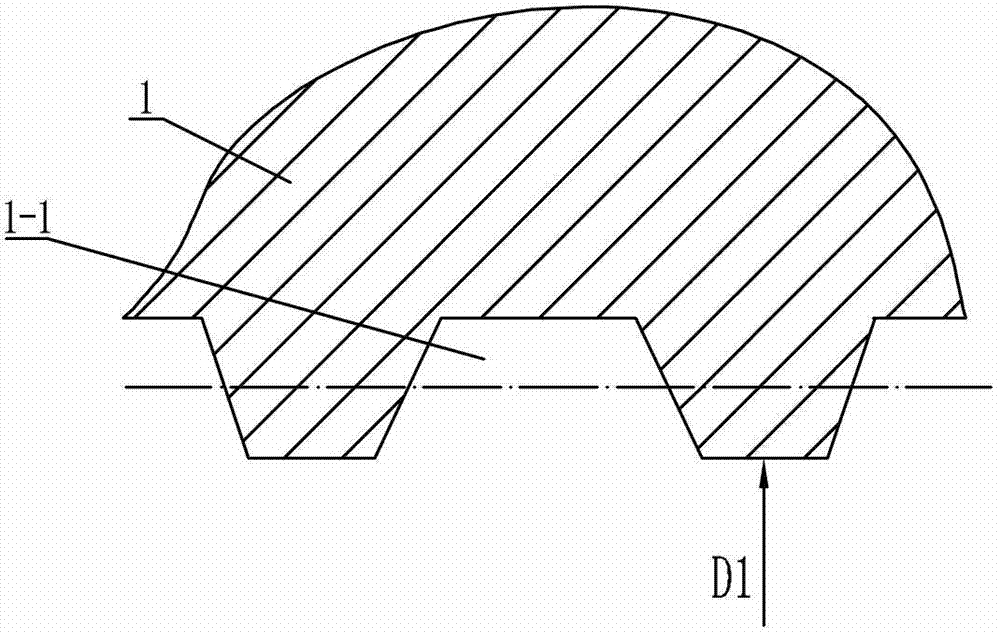

[0012] Step 1. The clamping and alignment of the outer ring parts, first remove the tool table of the lathe, and adjust the machining center of the trapezoidal threaded hole 1-1 to be processed on the upper end surface of the outer ring part 1 to be equal to the center of the chuck rotation , press the outer ring part 1 on the small pallet, align the trapezoidal threaded hole 1-1 to be processed, and press the outer ring part 1;

[0013] Step 2, drill the bottom hole, and drill a bottom hole with a diameter of D1 on the upper end surface of the outer ring part 1, and the diameter D1 is the small diameter of the trapezoidal internal thread hole 1-1 to be processed;

[0014] Step 3, thread turning of trapezoidal internal thread hole, remove the chuc...

specific Embodiment approach 2

[0021] Embodiment 2: In step 3 of this embodiment, the spindle speed of the lathe is 45 r / min. Such setting meets the design requirements and actual processing needs. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: In step 4 of this embodiment, the spindle speed of the lathe is 30 r / min. Such setting meets the design requirements and actual processing needs. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com