Beneficiation method suitable for alterated rock type gold ores

A mineral processing method and gold ore technology, applied in the direction of solid separation, etc., can solve the problems of low recovery rate of gold-bearing minerals, heavy pollution, high energy consumption, etc., to solve the problem of material blocking and ore over-crushing, no dust pollution, reduce dust grinding cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

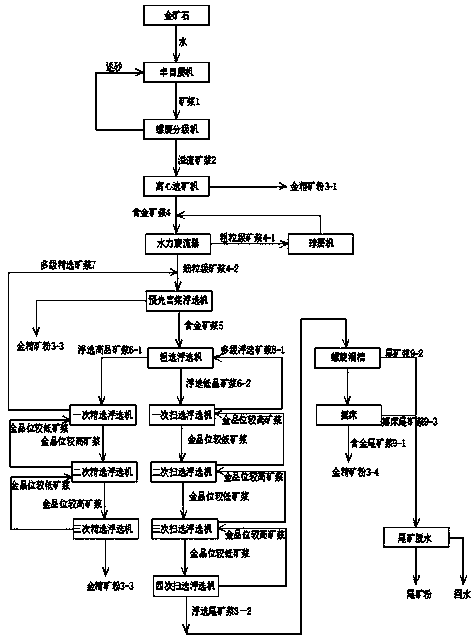

Image

Examples

Embodiment 1

[0047] A beneficiation method suitable for altered rock type gold ore, the method comprises the following steps:

[0048] Step 1. Grinding:

[0049] Altered rock type gold ore obtained by mining. This type of ore comes from 600 meters underground in the Lizi mining area. The gold content is 5g / t. The conveyor is fed into the semi-autogenous mill, and at the same time water is supplied to the semi-autogenous mill. The gold ore is crushed and coarsely ground in the semi-autogenous mill to form a slurry with a concentration of 77%.

[0050] Step 2. Centrifugal re-election:

[0051] (1), rough classification:

[0052] The ore pulp 1 in step 1 flows to the spiral classifier for coarse classification to realize the separation of coarse-grained ore and fine-grained ore, wherein the fine-grained ore is less than 0.074mm The content of the ore is 42%, and the remaining Both are defined as coarse-grained ore, and the coarse-grained ore is returned to the semi-autogenous mill for furt...

Embodiment 2

[0069] A beneficiation method suitable for altered rock type gold ore, the method comprises the following steps:

[0070] Step 1. Grinding:

[0071] Altered rock type gold ore obtained by mining, this type of ore comes from 350 meters underground in the Lizi mining area, and its gold content is 1.5g / t. In the raw ore, fine mud below 20 microns The content is 22%, and the maximum particle size is 550mm. It is fed into the semi-autogenous mill by the belt conveyor, and water is supplied to the semi-autogenous mill at the same time. The gold ore is crushed and coarsely ground in the semi-autogenous mill to form a slurry with a concentration of 85%. 1.

[0072] Step 2. Centrifugal re-election:

[0073] (1), rough classification:

[0074] The ore pulp 1 in step 1 flows to the spiral classifier for coarse classification, so as to realize the separation of coarse-grained ore and fine-grained ore. The fine-grained ore is 46% of the ore with a particle size of less than 0.074mm, and...

Embodiment 3

[0091] A beneficiation method suitable for altered rock type gold ore, the method comprises the following steps:

[0092] Step 1. Grinding:

[0093] Altered rock type gold ore obtained by mining, this type of ore comes from 500 meters underground in the Lizi mining area, and its gold content is 2g / t, silver content is 60g / t, and lead content is 1.2%. In the raw ore, the content of fine mud below 20 microns is 20%, and the maximum particle size is 600mm. It is fed into the semi-autogenous mill by a belt conveyor, and water is supplied to the semi-autogenous mill at the same time. The gold ore is crushed and crushed in the semi-autogenous mill. Coarse grinding to form a slurry with a concentration of 75%.

[0094] Step 2. Centrifugal re-election:

[0095] (1), rough classification:

[0096] The ore pulp 1 in step 1 flows to the spiral classifier for coarse classification to realize the separation of coarse-grained ore and fine-grained ore, wherein the fine-grained ore is 40% of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com