Method and device for improving COD detection precision of high-chlorine wastewater

A high-chlorine wastewater and detection accuracy technology, applied in the field of COD detection, can solve the problems of affecting the chlorine gas correction COD measurement results, the reduction of the contact surface area between gas and liquid, and the inability to clearly guide on-site production, etc., to increase the conversion rate of chlorine gas, The gas flow rate is uniform and stable, which solves the problem of difficult detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

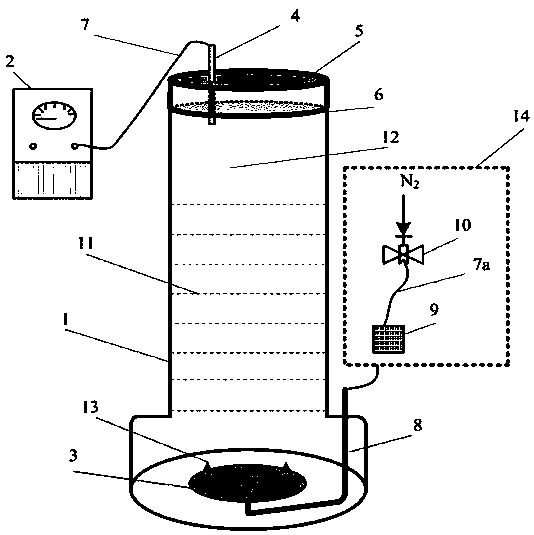

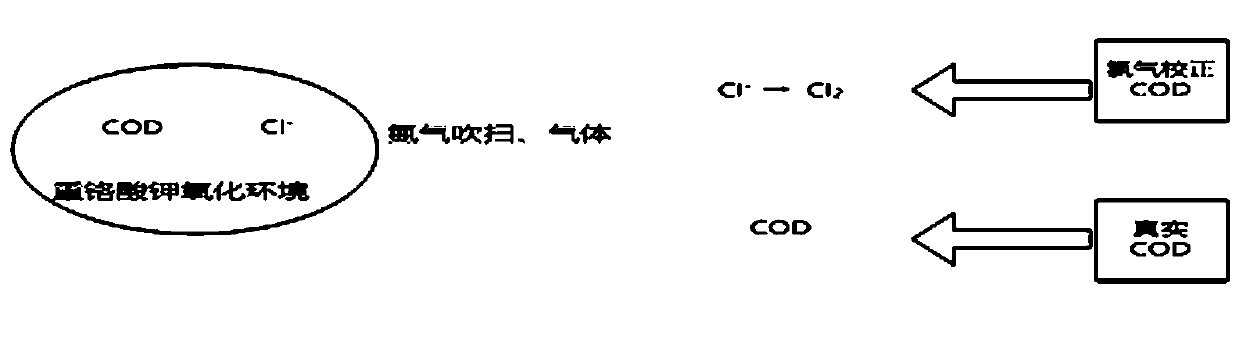

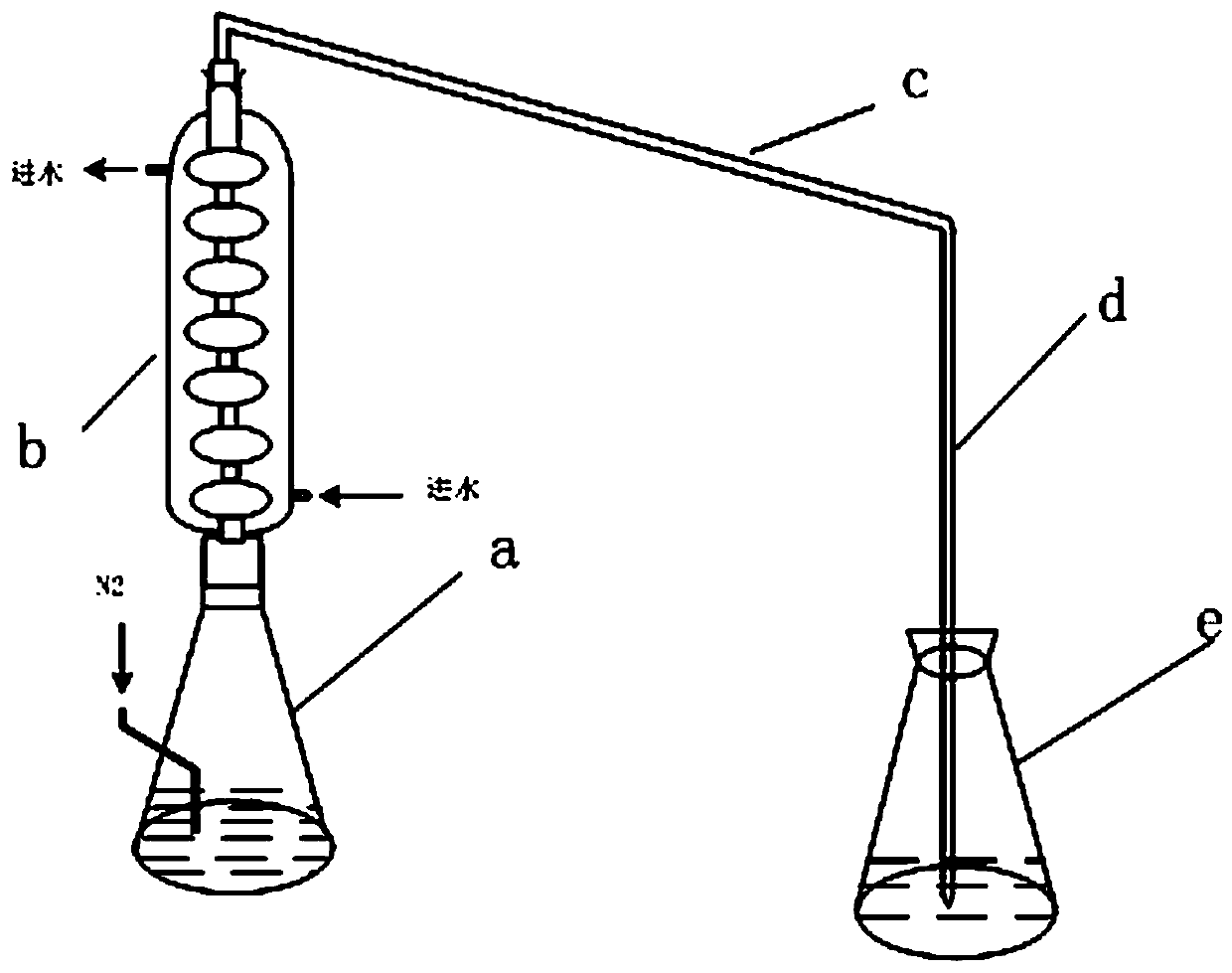

[0037] A method for improving the detection accuracy of COD in high-chlorine wastewater, comprising constant inert gas flow rate, increasing air tightness, improving chlorine gas absorption efficiency and method realization process; the inert gas source is nitrogen;

[0038] The constant gas flow rate is based on the determination of the existing high-chlorine wastewater COD detection method so that the blowing rate of the nitrogen gas source into the oxidizing environment is constant, so that the gas flow rate of the entire high-chloride wastewater COD detection system remains in a constant state; according to the detection The nitrogen flow rate is set according to the specific requirements of the sample properties and environmental conditions. The constant flow rate is changed from any value in the original variable 5-10mL / min to a quantitative gas flow rate of 10mL / min. The quantitative gas flow rate is conducive to oxidation to produce chlorine gas that enters the absorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com