Full-premixing gas gun with flame stabilizing function

A fully premixed, gas gun technology, applied in the direction of burners, combustion methods, combustion types, etc., can solve problems such as increased safety hazards, unstable pressure, gas leakage, etc., to achieve improved stability, slow flow rate, and reduced gas consumption. The effect of the possibility of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is attached Figure 1-4 The application is described in further detail.

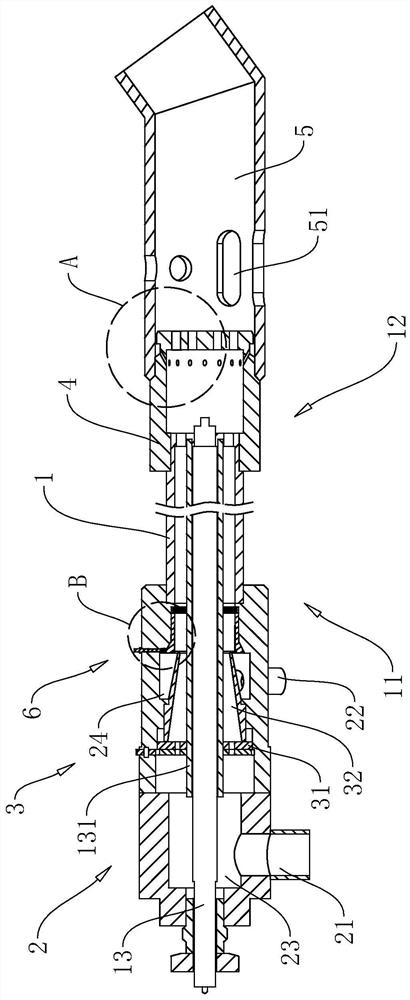

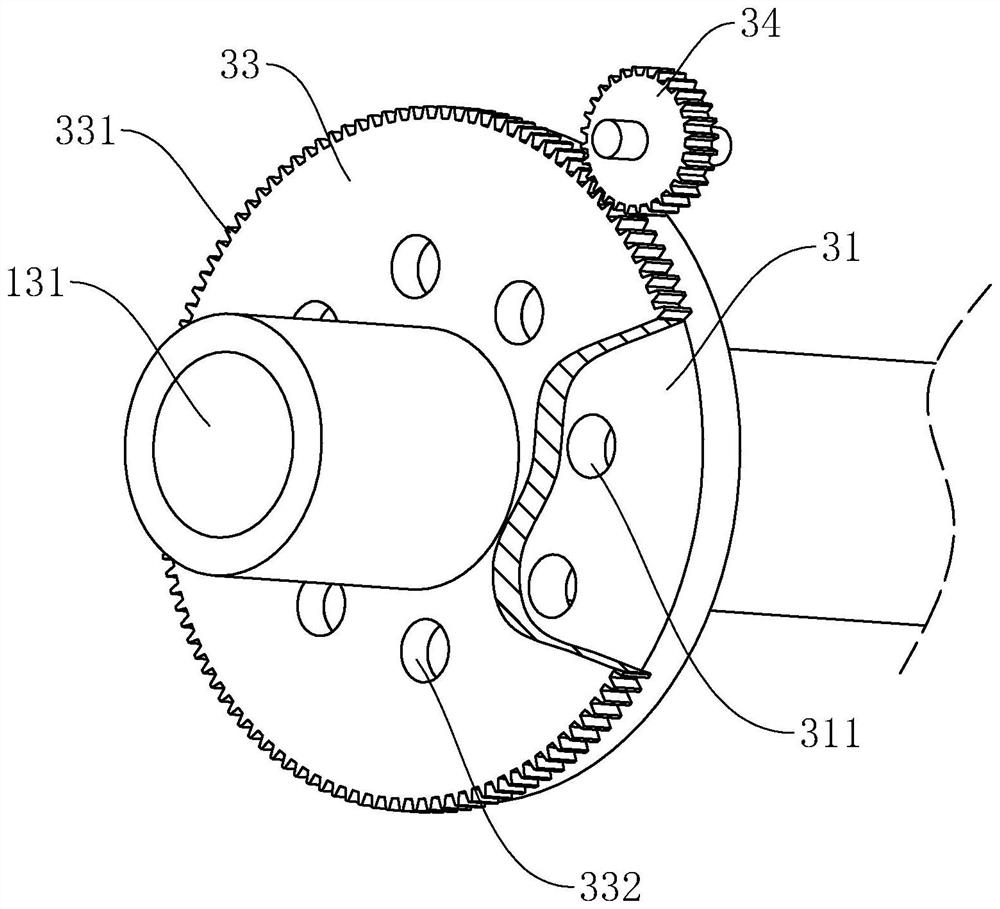

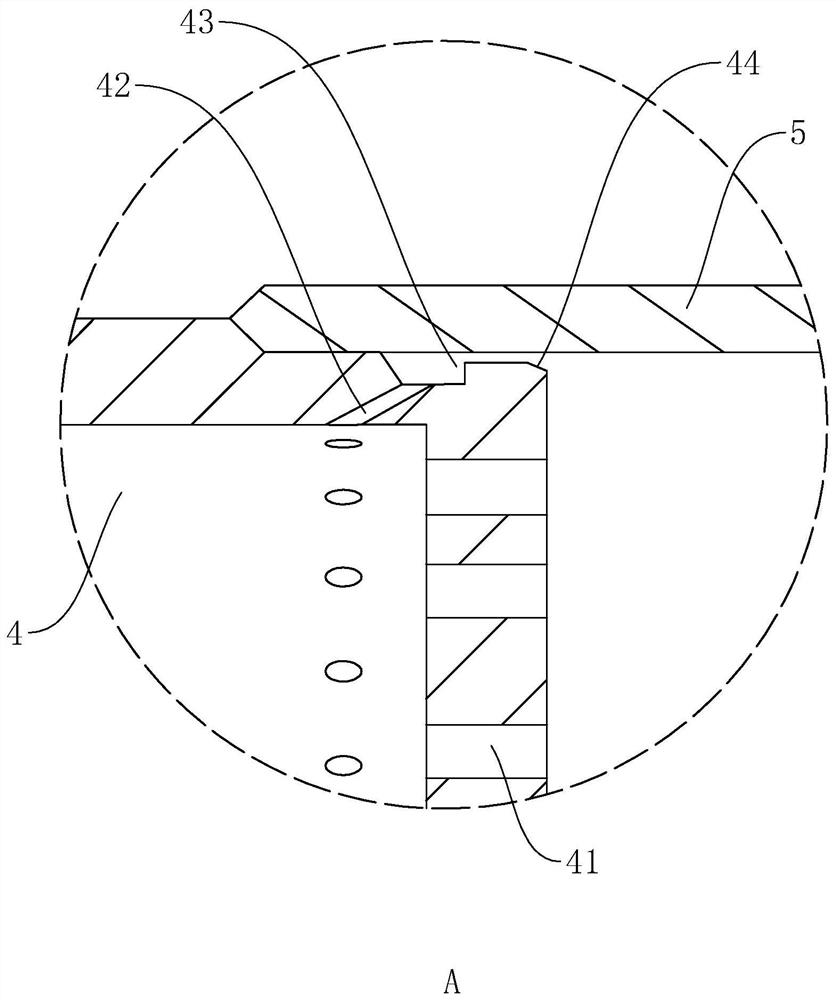

[0037] The embodiment of the present application discloses a fully premixed gas gun with a flame stabilizing function, such as figure 1As shown, it includes a premixing tube 1, an ignition electrode 13, a ventilation seat tube 2, a splitter nozzle 4 and a flame spraying tube 5. The premixing tube 1 is a long straight tube, and the ignition electrode 13 is located in the premixing tube 1 and the two are the same. The shaft, the ventilation seat tube 2, the premixing pipe 1, the splitting spray tube 4 and the fire spray pipe 5 are connected in sequence. One end of the premixing pipe 1 is the operation end 11, and the other end is the fire end 12. The ventilation seat tube 2 is installed on the operation end 11 of the premixing pipe 1. Fire end 12.

[0038] Such as figure 1 As shown, one end of the ignition electrode 13 protrudes from the operating end 11 of the ventilation seat tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com