Positive-pressure combustion low-NOx combustor

A positive pressure combustion and burner technology, which is applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve problems such as no good solutions, and achieve the effect of easy manufacture and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

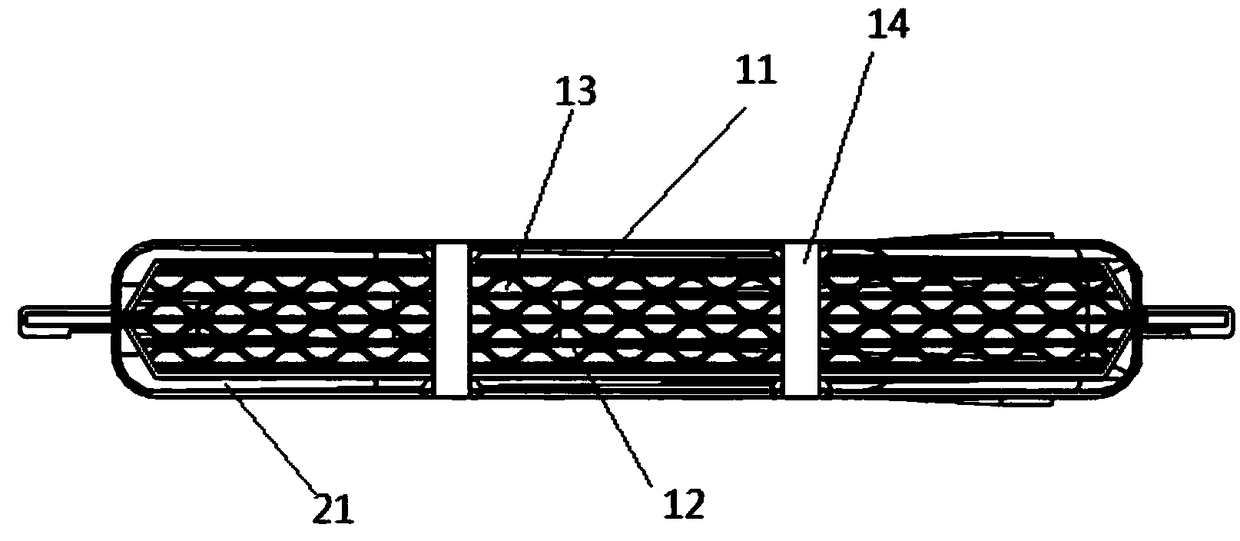

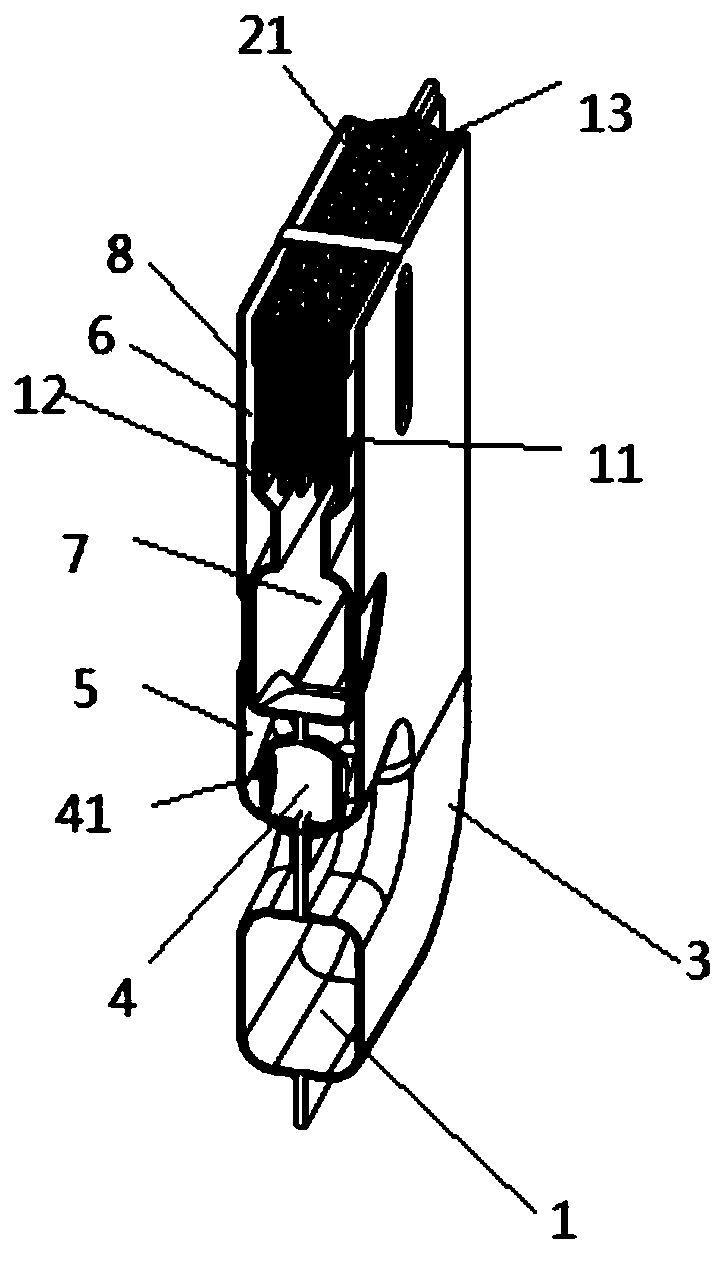

[0032] Such as Figure 3-4 As shown, a positive pressure combustion low NOx burner, the burner includes a light gas introduction flow channel and a rich gas introduction flow channel, and the light gas introduction flow channel includes a light fire hole gas injection port connected in sequence 1. Light fire hole gas mixing chamber 3, light fire hole gas static pressure chamber 7 and fire hole assembly;

[0033] The described rich gas introduction circulation channel comprises the thick fire hole gas injection port 2, the thick fire hole gas mixing chamber 4 and the thick fire port gas balance chamber 5 connected in sequence, and also includes the thick fire hole gas coaming plate 8, the thick fire hole The gas coaming plate 8 surrounds the periphery of the fire hole assembly, and forms a thick fire hole gas outlet 21 between the fire hole assembly, and the thick fire hole gas outlet 21 is located on both sides of the semicircular fire hole 13 .

[0034] The gas injection por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com