Runner structure of a rubber mold

A rubber mold and runner technology, applied in the field of runner structure of rubber molds, can solve the problems of low temperature at the inner core, high scrap rate, lower production efficiency, etc., and achieve the effect of ensuring temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

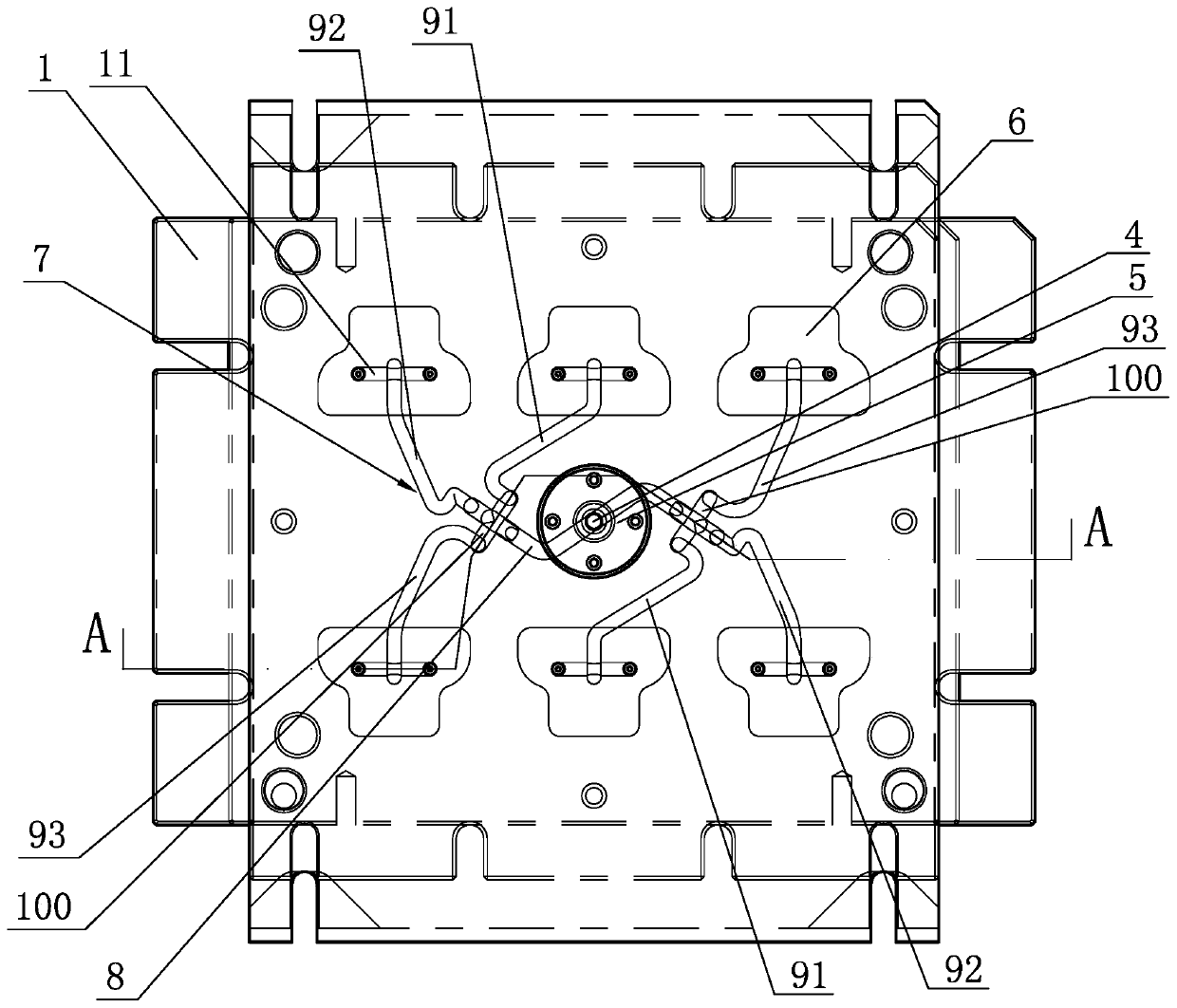

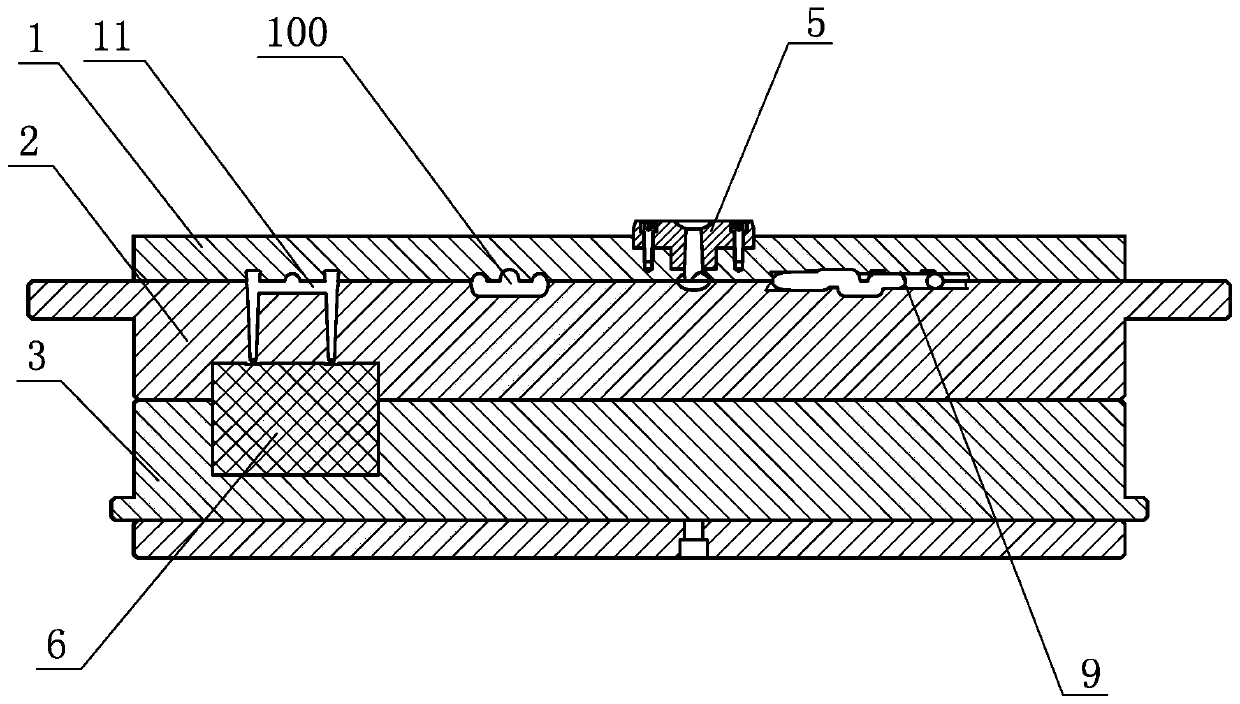

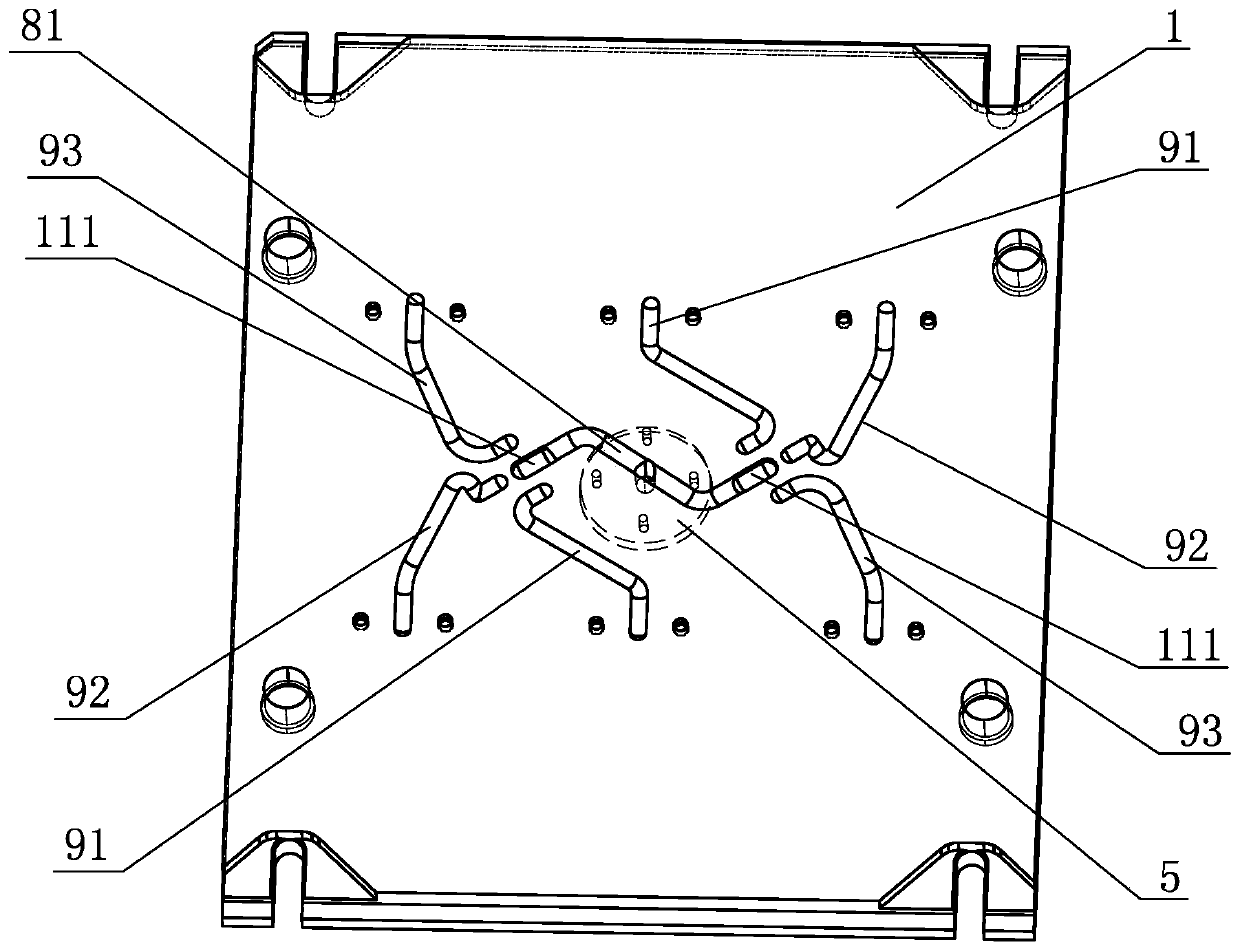

[0026] Embodiment: As shown in the figure, a runner structure of a rubber mold includes a runner plate 1, an upper mold plate 2 and a lower mold plate 3 arranged from top to bottom, and the runner plate 1 is provided with a glue injection hole 4. A glue injection nozzle 5 is inserted in the glue hole 4, at least two cavities 6 are processed between the upper template 2 and the lower template 3, and a runner 7 is provided between the runner plate 1 and the upper template 2, and the runner 7 includes A primary flow channel 8 with a circular cross section, at least two secondary flow channels 9, two chambers 100 for inverting the rubber material, and a tertiary flow channel 11 corresponding to the secondary flow channel 9, the primary The middle part of the flow channel 8 communicates with the glue injection hole 4, and the two ends of the primary flow channel 8 are respectively connected with chambers 100. The primary flow channel 8 includes the upper half flow channel 81 arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com