Mould casting device and method for semiconductor package

A semiconductor and mold-casting technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve punching, air bubbles and holes, large differences in the properties of sealing plastics, and long sealing process cycles. and other problems, to achieve uniform flow and filling, reduce manufacturing costs, and reduce air holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

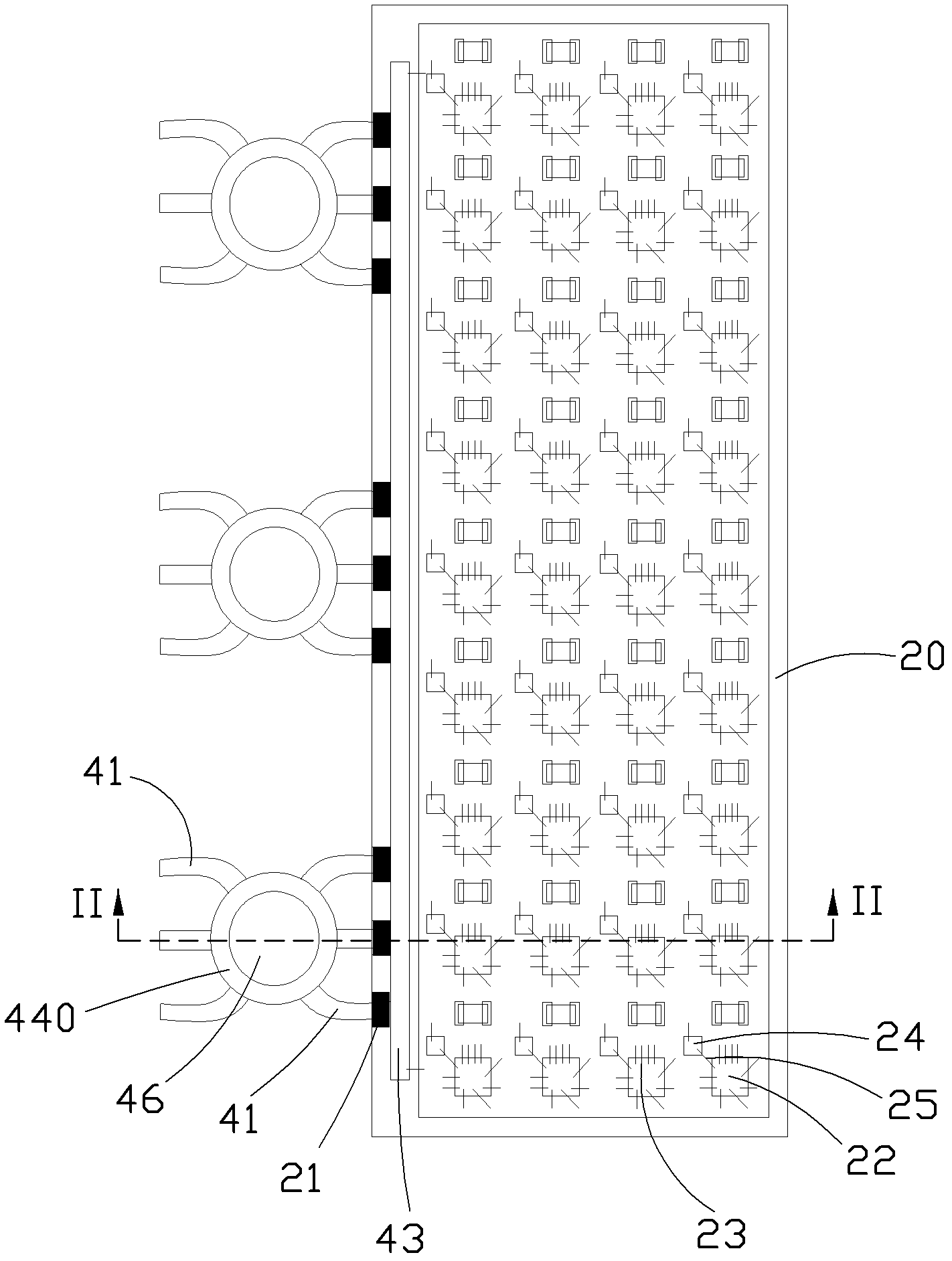

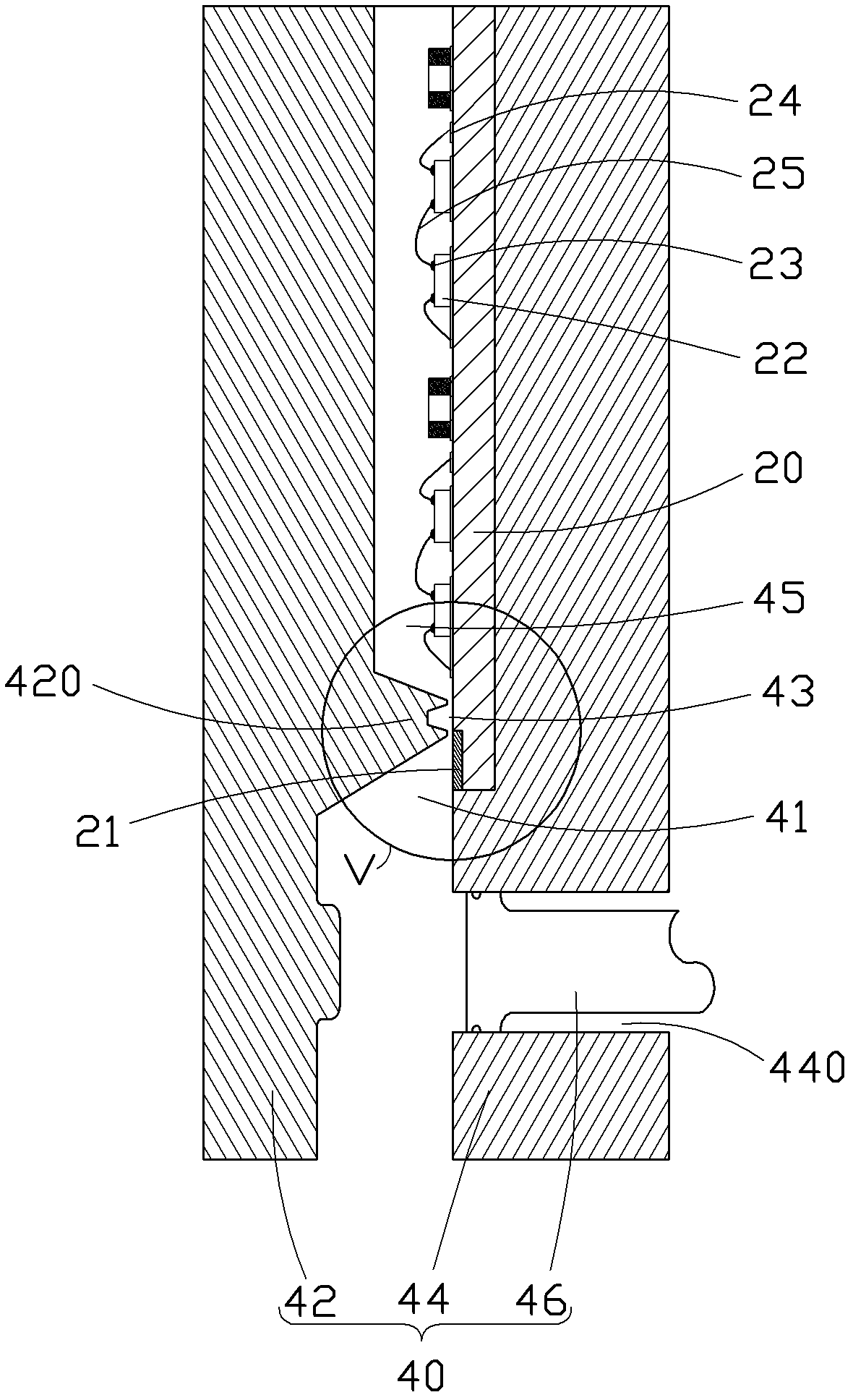

[0053] Please refer to figure 1 with figure 2 , the substrate 20 suitable for packaging, the material of the substrate 20 can be glass epoxy resin (Flame-retardant epoxy-glass fabric composite resin, FR-4, RF-5) or bismaleimide (Bismaleimide Triazine, BT). The substrate 20 is provided with a plurality of chips 22 , a plurality of welding feet 24 and a plurality of welding wires 25 . The chip 22 is provided with a plurality of welding pads 23 , and the welding pads 23 and the welding feet 24 are connected through the bonding wires 25 to electrically connect the chip 22 and the substrate 20 .

[0054] A debonding layer 21 is disposed on one side of the substrate 20 , and the debonding layer 21 is embedded in the substrate 20 . In this embodiment, the debonding layer 21 is exposed on the surface of the substrate 20 and is coplanar with the surface of the substrate 20 where the chip 22 is located.

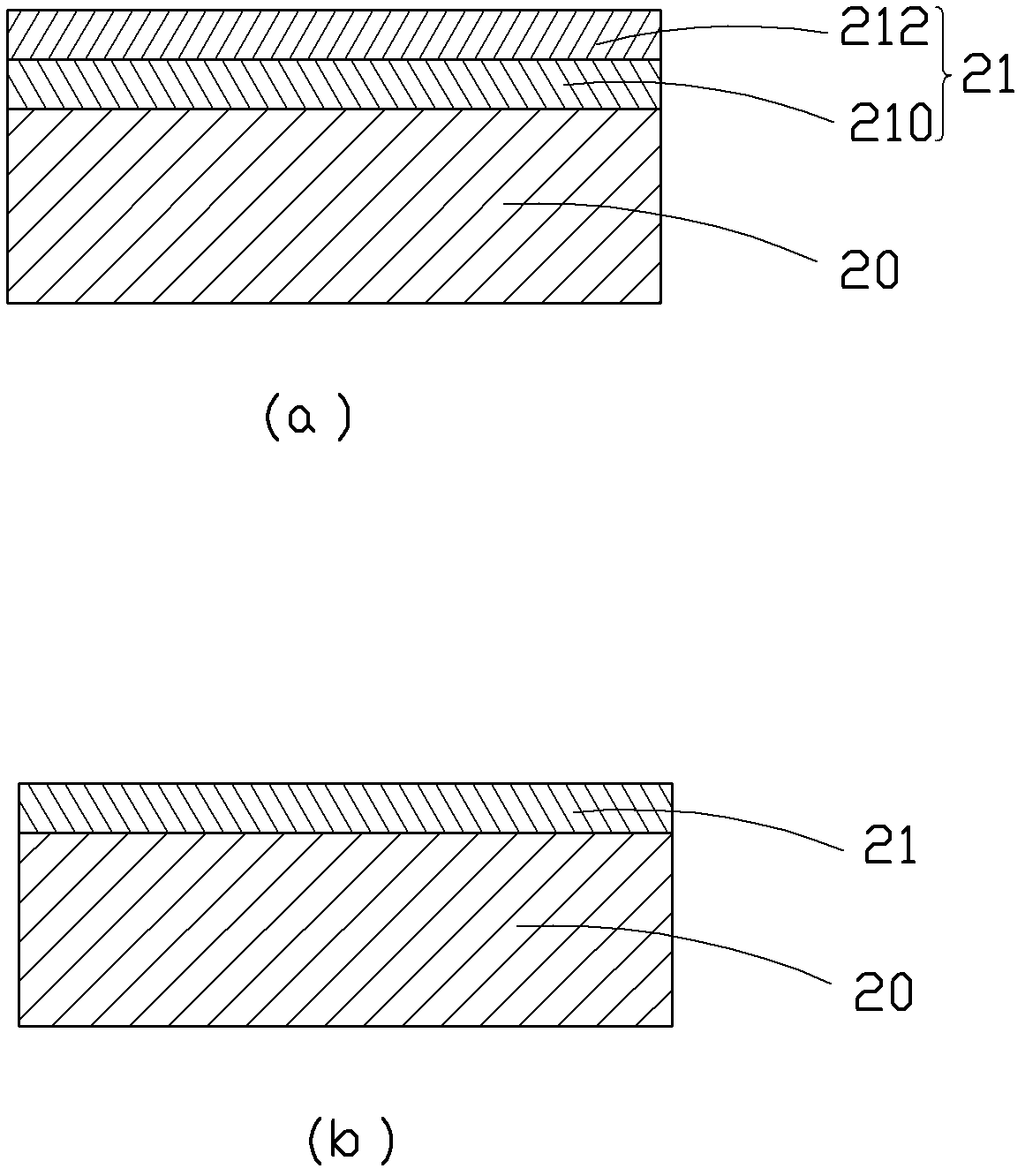

[0055] Please refer to image 3 , wherein (a) the debonding layer 21 on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com