Gate late casting precise casting technology facilitating wax discharge and gas exhaust

A technology of precision casting and castings, which is applied in the field of precision casting of ram castings. It can solve the problems of air suffocation, large pockets and pinholes of ram castings, and difficult discharge of mold shell gas, so as to improve the quality of castings and reduce the effect of air pockets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

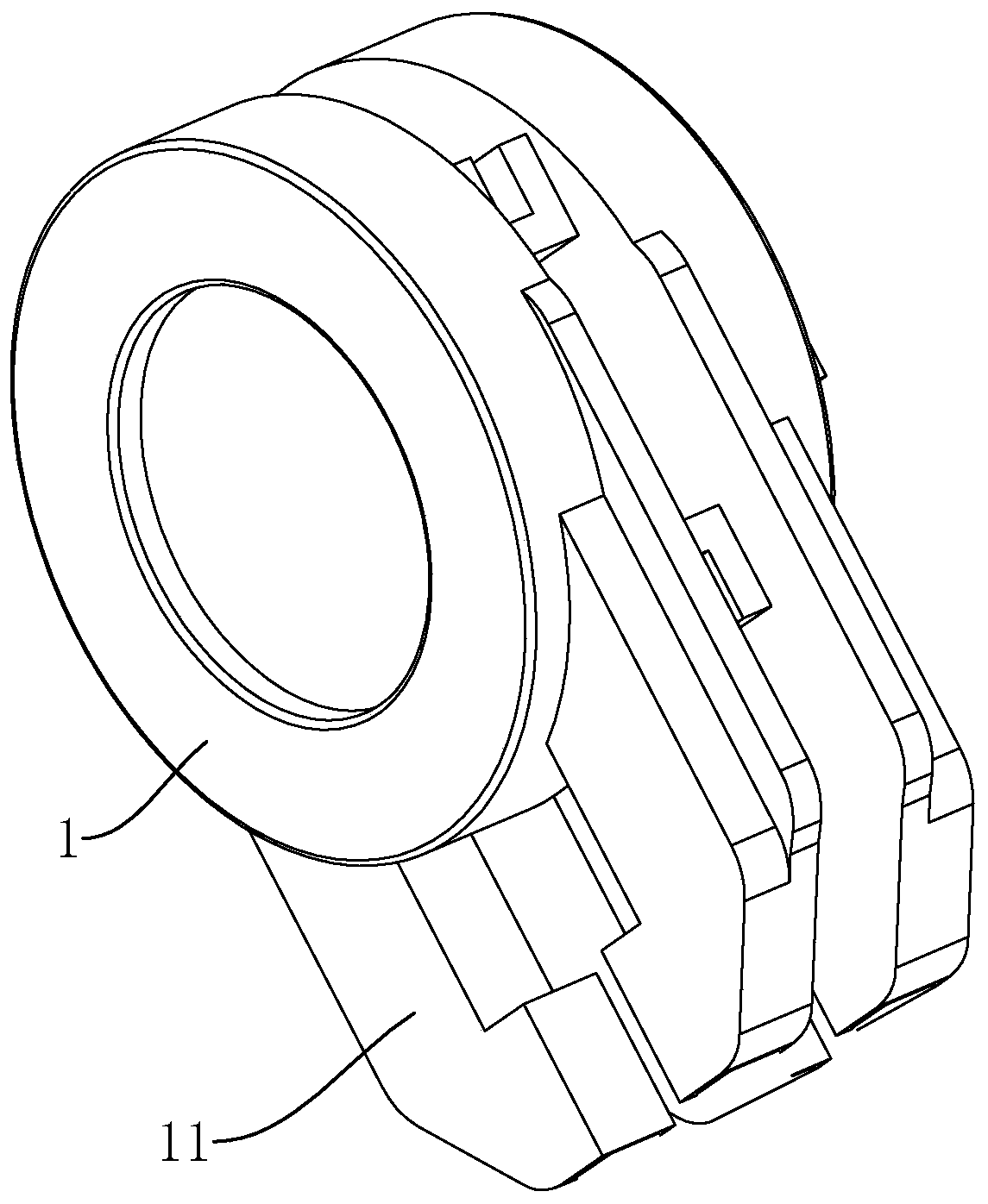

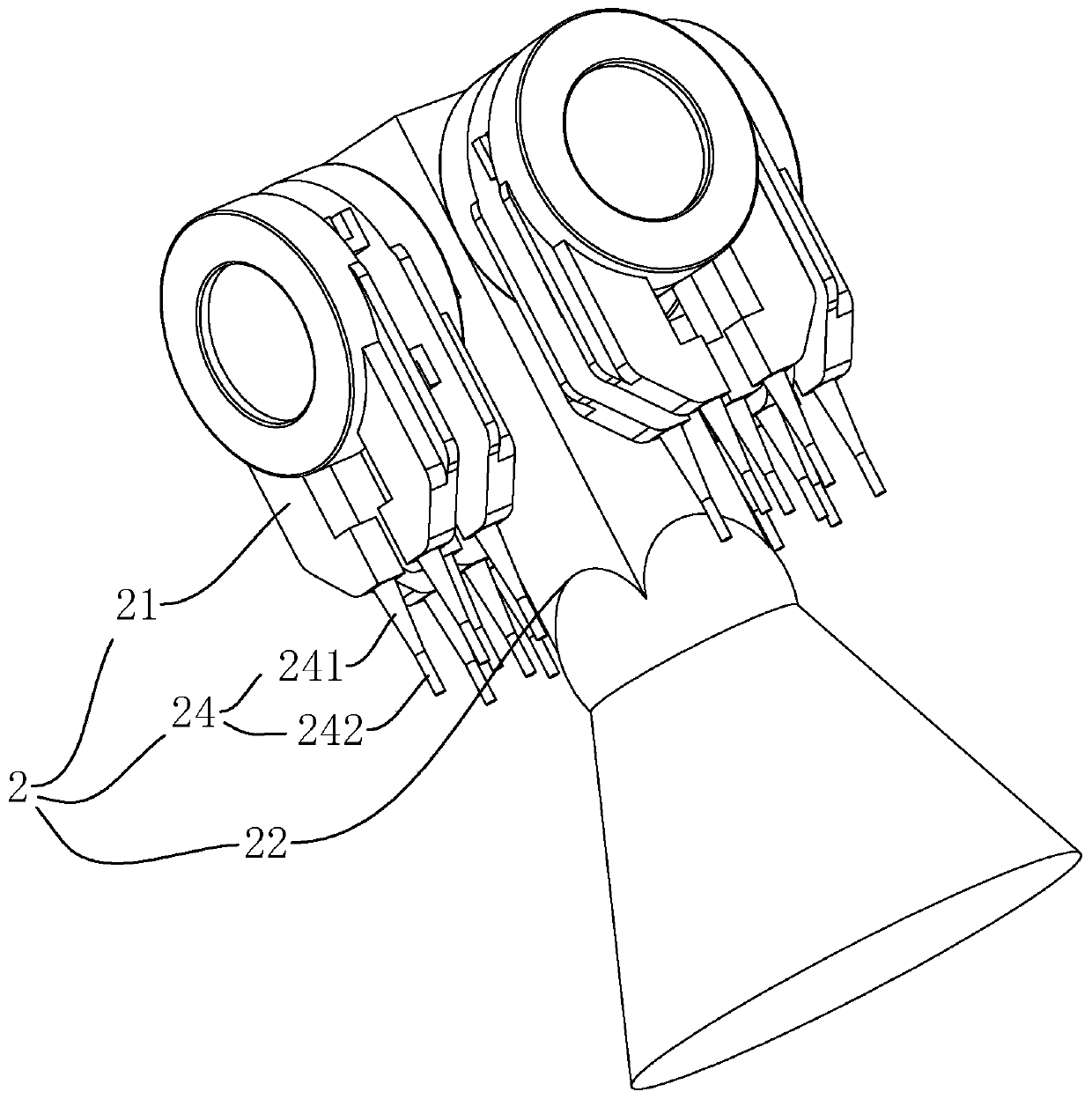

[0037] The specific dimensions of the wax-discharging nail 24 are as follows: the diameter of the cylindrical part 242 is 1.3mm, and the length is 11mm; The cylindrical portion 242 is equal in diameter.

[0038] A gate casting investment casting process that is convenient for wax removal and exhaust, comprising the steps:

[0039] S1 Pressed wax: Inject molten wax liquid into the mold to form a precision wax model 21, then water-cool and wax repair;

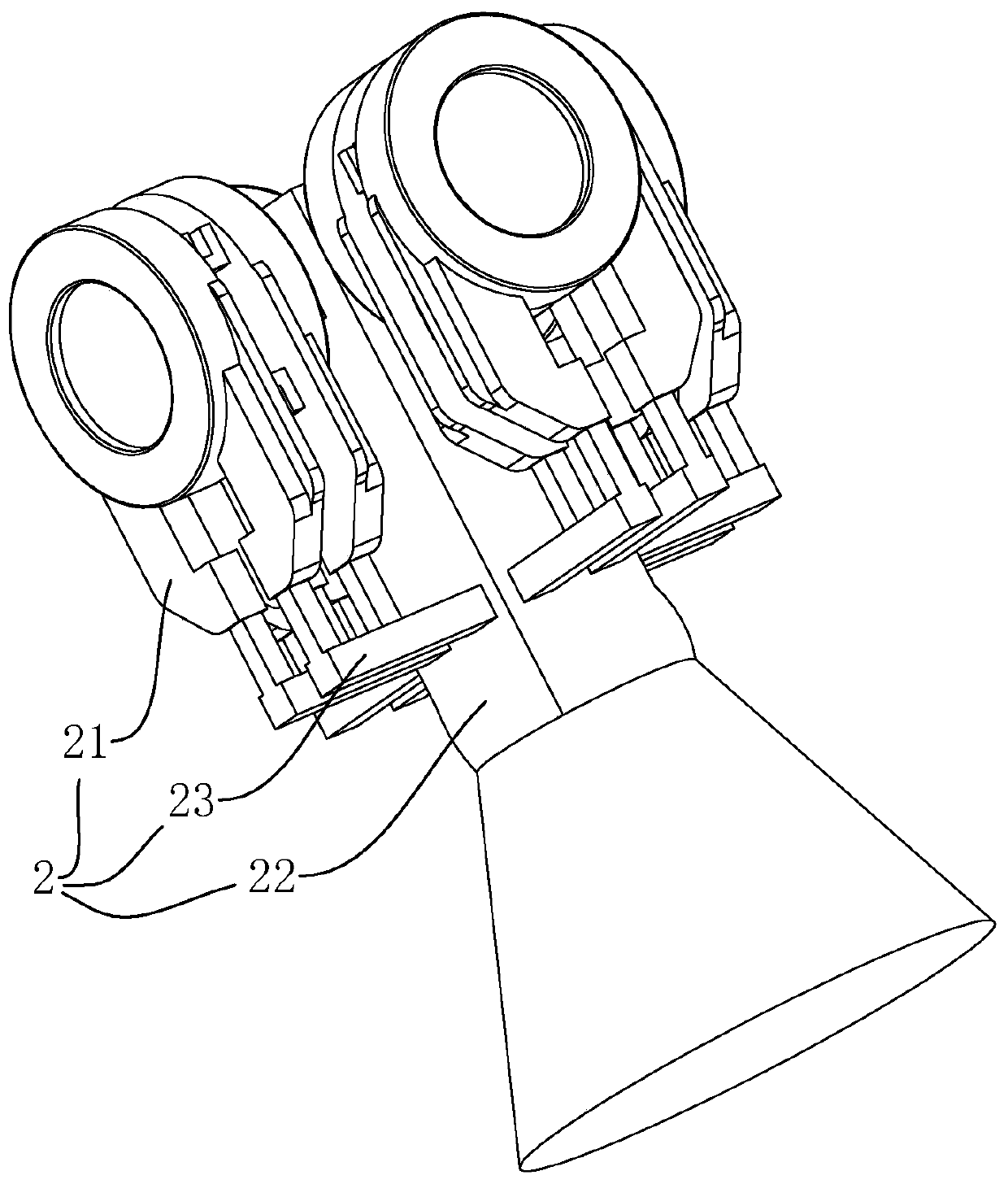

[0040] S2 group tree: melt the four precision wax molds 21 and the sprue 22 into one, and then place four wax nails 24 on the top of each precision wax mold 21, and obtain the wax mold group 2 after cleaning;

[0041] S3 shell making:

[0042] The first step is to pre-wet the wax module 2 first, then immerse the wax module 2 in the alkaline silica sol, so that the silica sol evenly covers the surface of the wax module 2, then spray sand, and dry to form the first layer;

[0043] In the second step, repeat the first step sever...

Embodiment 2

[0055] The specific dimensions of the wax-discharging nail 24 are as follows: the diameter of the cylindrical part 242 is 1.5mm, and the length is 9mm; The cylindrical portion 242 is equal in diameter.

[0056] A gate casting investment casting process that is convenient for wax removal and exhaust, comprising the steps:

[0057]S1 Pressed wax: Inject molten wax liquid into the mold to form a precision wax model 21, then water-cool and wax repair;

[0058] S2 group tree: melt the four precision wax molds 21 and the sprue 22 into one, and then place four wax nails 24 on the top of each precision wax mold 21, and obtain the wax mold group 2 after cleaning;

[0059] S3 shell making:

[0060] The first step is to pre-wet the wax module 2 first, then immerse the wax module 2 in the alkaline silica sol, so that the silica sol evenly covers the surface of the wax module 2, then spray sand, and dry to form the first layer;

[0061] In the second step, repeat the first step several...

Embodiment 3

[0073] The specific dimensions of the wax-discharging nail 24 are as follows: the diameter of the cylindrical part 242 is 1.4mm, and the length is 10mm; The shape portion 242 is equal in diameter.

[0074] A gate casting investment casting process that is convenient for wax removal and exhaust, comprising the steps:

[0075] S1 Pressed wax: Inject molten wax liquid into the mold to form a precision wax model 21, then water-cool and wax repair;

[0076] S2 group tree: melt the four precision wax molds 21 and the sprue 22 into one, and then place four wax nails 24 on the top of each precision wax mold 21, and obtain the wax mold group 2 after cleaning;

[0077] S3 shell making:

[0078] The first step is to pre-wet the wax module 2 first, then immerse the wax module 2 in the alkaline silica sol, so that the silica sol evenly covers the surface of the wax module 2, then spray sand, and dry to form the first layer;

[0079] In the second step, repeat the first step several tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com