Preparation method of thick and large-section aluminum alloy casting

A technology for aluminum alloy castings and large sections, which is used in casting molding equipment, metal processing equipment, casting molds, etc. Improved mechanical strength, reduced air pockets, and reduced processing man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

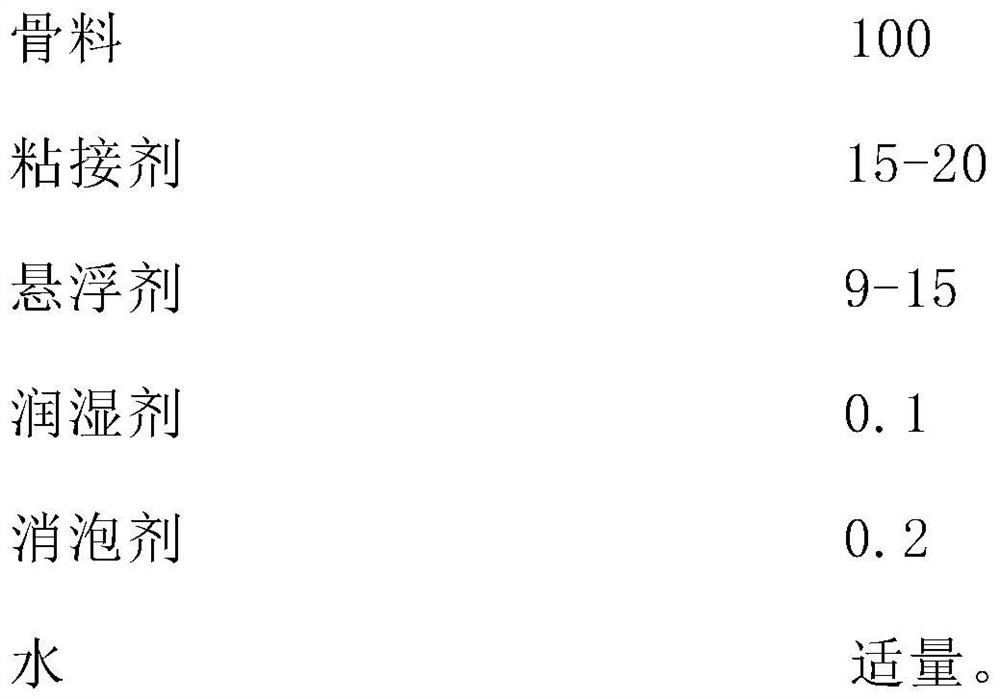

[0019] A method for preparing aluminum alloy castings with thick and large cross-sections. The preparation method includes the following steps: a mold preheating process; a metal paint spraying process; a casting process; and a molding and core pulling process.

[0020] The mold reservation process is as follows: the mold is preheated to 180°C for 2 hours, and then cooled to 80-90°C.

[0021] The casting process is as follows: the mold sprayed by the metal paint spraying process is heated to 210°C, the pouring temperature is 710°C, and when the furnace temperature is higher than 730°C, the casting starts after standing still.

Embodiment 2

[0023] A method for preparing aluminum alloy castings with thick and large cross-sections. The preparation method includes the following steps: a mold preheating process; a metal paint spraying process; a casting process; and a molding and core pulling process.

[0024] The mold reservation process is as follows: the mold is preheated to 200°C for 1 hour, and then cooled to 80-90°C.

[0025] The casting process is as follows: the mold sprayed by the metal paint spraying process is heated to 230°C, the pouring temperature is 720°C, and when the furnace temperature is higher than 730°C, the casting starts after standing.

Embodiment 3

[0027] A method for preparing aluminum alloy castings with thick and large cross-sections. The preparation method includes the following steps: a mold preheating process; a metal paint spraying process; a casting process; and a molding and core pulling process.

[0028] The mold presetting process is as follows: the mold is preheated to 220°C for 1 hour, then cooled to 80-90°C.

[0029] The casting process is as follows: the mold sprayed by the metal paint spraying process is heated to 250°C, the pouring temperature is 730°C, and when the furnace temperature is higher than 730°C, the casting starts after standing.

[0030] Embodiment 1, 2, 3 Casting reduces processing man-hours by 70-80%, and improves mechanical strength by 20-25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com