Device for pricking bubbles in semi-finished rubber sheet of rubber product

A technology for rubber products and semi-finished products, applied in the direction of coating, etc., can solve the problems of rubber products such as air pockets, and achieve the effects of improving production efficiency, improving the qualification rate, and reducing the phenomenon of pocket gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

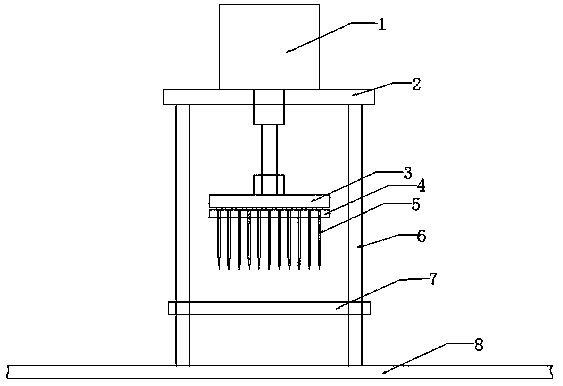

[0021] Standard Pneumatic Cylinder (1) is a standard SC-type pneumatic cylinder, which can reciprocate after being connected to compressed air, and the reciprocating movement of the cylinder can be controlled by a five-position three-way valve.

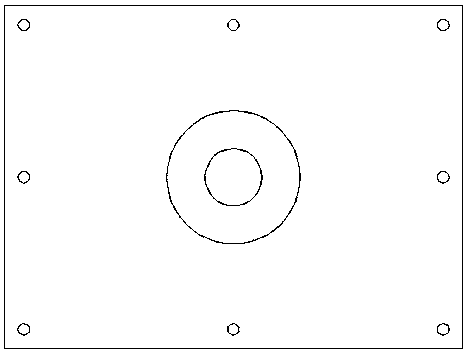

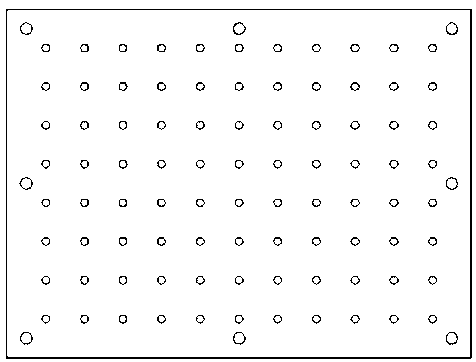

[0022] Four connecting rods (6) are leading screws, which can be fixed with nuts. Cylinder fixing plate (2), cylinder joint connection part (3), steel needle fixing plate (4), steel needle (5), four connecting rods (6), film shedding plate (7) and platform (8) components The relative position of can be adjusted. Cylinder fixing plate (2), cylinder joint connection part (3), steel needle fixing plate (4), steel needle (5), four connecting rods (6), film shedding plate (7), platform (8) can pass Manufactured by machining, and then bolts and nuts are used to fix the various parts as a whole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com