Multicompressor parallel connection unit using flooded type shell and tube evaporator

A multi-compressor and evaporator technology, applied in the field of compressor units, can solve the problems of increasing the size of the unit, reducing the heat exchange efficiency of the heat exchanger, and large design of the evaporator, so as to improve heat exchange efficiency, protect normal operation, reduce The effect of charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

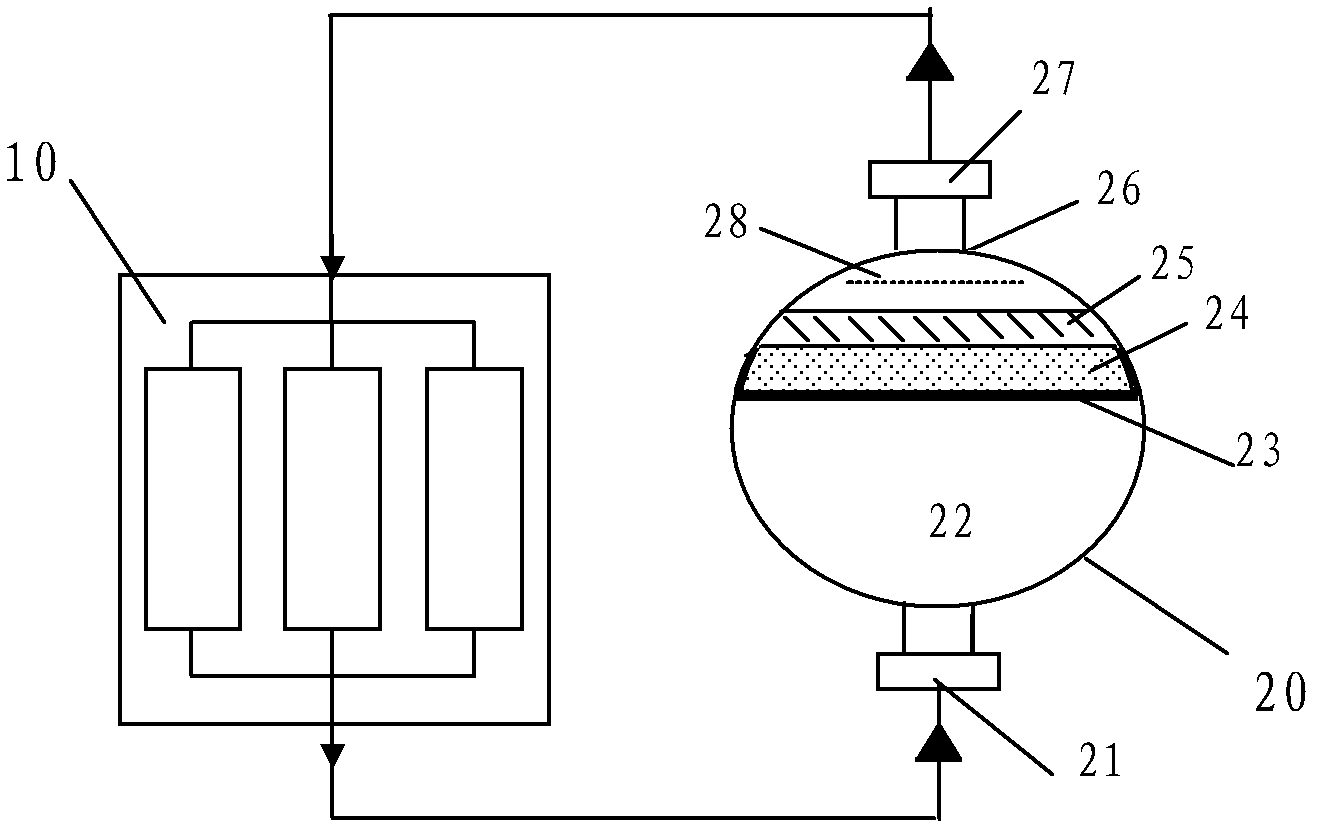

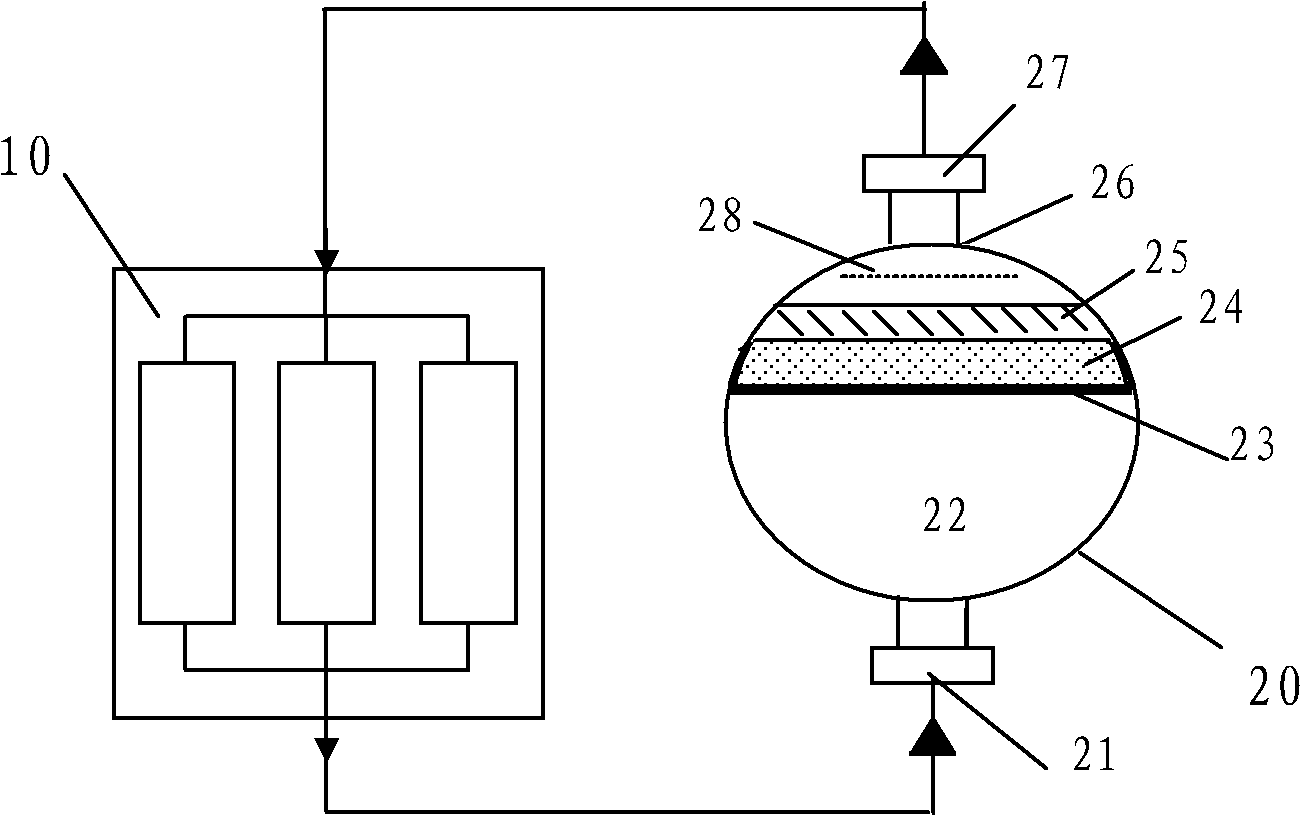

[0019] see figure 1 , the multi-compressor parallel unit using the flooded shell-and-tube evaporator of the present invention includes a multi-compressor parallel unit composed of a plurality of compressors connected in parallel (this embodiment adopts a unit composed of three scroll compressors connected in parallel) 10 And a flooded shell-and-tube evaporator 20 connected to the expansion valve of the multi-compressor parallel unit 10 .

[0020] The flooded shell-and-tube evaporator 20 includes: a shell 22, in which a heat exchange tube with brine flows, and the liquid refrigerant of the multi-compressor parallel unit 10 comes out through the expansion valve and is placed in the shell The connection nozzle 21 at the inlet end of the body 22 enters the housing 22 of the evaporator and evaporates into a gaseou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com