Etching groove, method for conveying etching liquid and etching system

An etching system and etching tank technology, applied in the field of etching systems, can solve the problems of inter-chip etching uniformity, reduce intra-chip etching uniformity, and uneven flow rate, etc., and achieve improved intra-chip etching uniformity Efficiency and inter-chip etching uniformity, prevention of inter-chip cross-contamination, uniform and stable flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

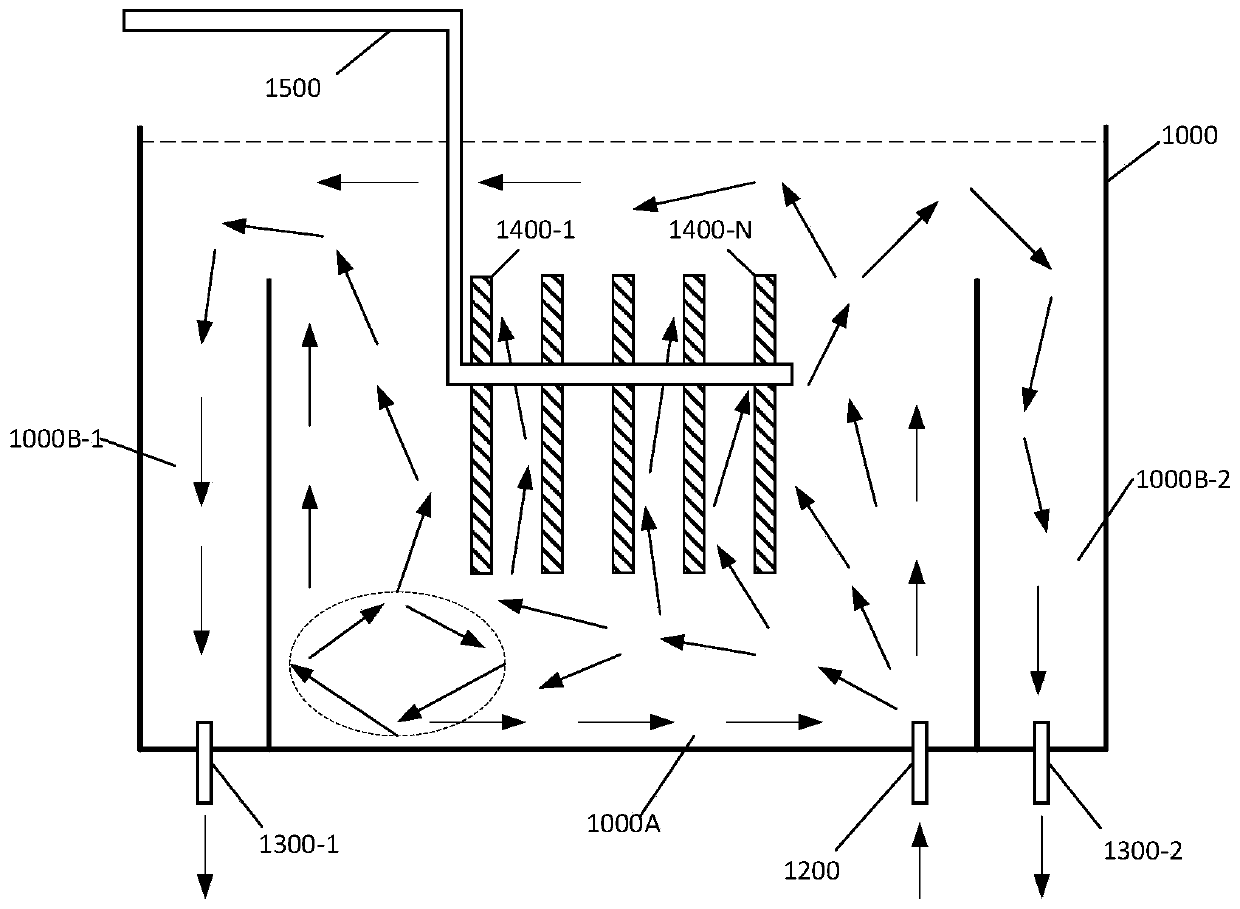

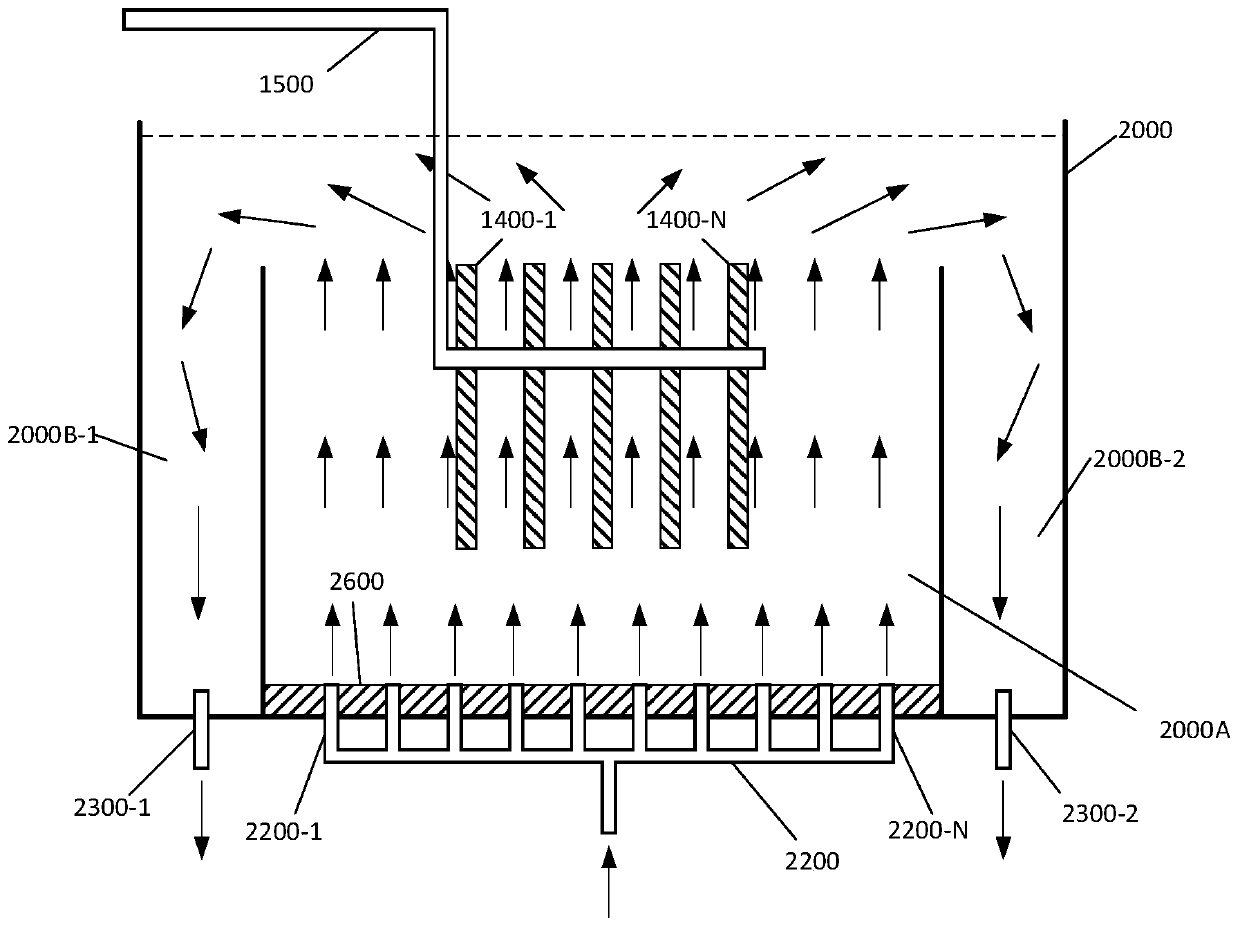

[0070] Example 1, an etching groove, wherein, the etching groove comprises:

[0071] A plurality of delivery nozzles, the plurality of delivery nozzles are evenly distributed on the bottom of the etching tank, and the plurality of delivery nozzles are configured to deliver the etching liquid into the etching tank in parallel.

example 2

[0072] Example 2. The etching groove as described in Example 1, wherein:

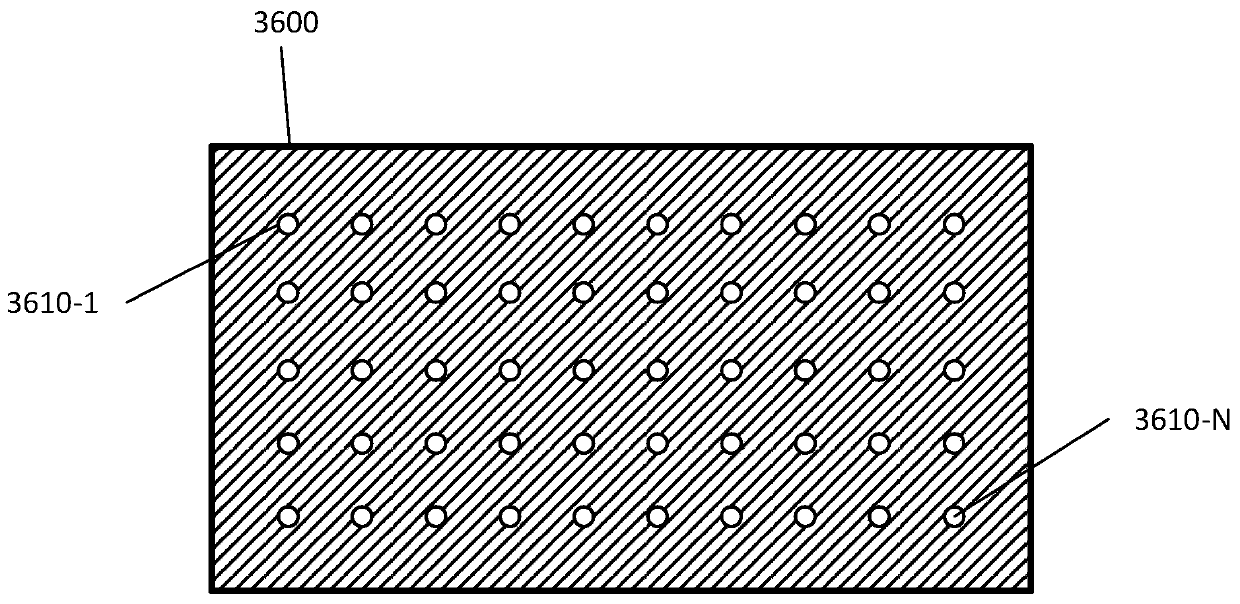

[0073] The etching tank also includes a first screen, the first screen is positioned at the bottom of the etching tank and has a plurality of holes, each delivery nozzle in the plurality of delivery nozzles is fixed on the corresponding slots in the plurality of slots of the first screen.

example 3

[0074] Example 3. The etching groove as described in Example 2, wherein:

[0075] The opening of each delivery nozzle in the plurality of delivery nozzles is not higher than the upper surface of the first screen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com