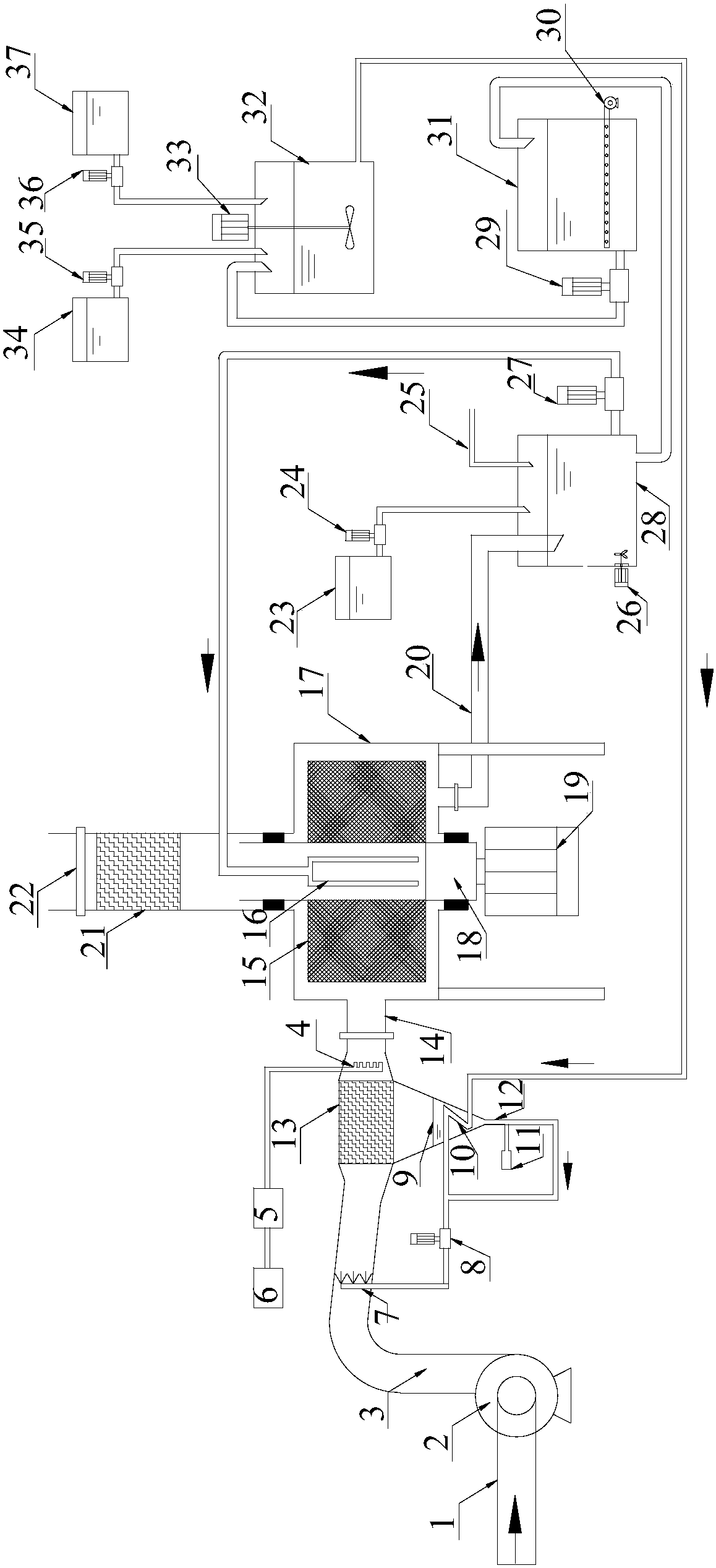

A coal-fired boiler flue gas wet desulfurization and denitrification and wastewater treatment device and process

A technology for wet desulfurization and wastewater treatment, applied in gas treatment, separation methods, air quality improvement, etc., can solve problems such as easily ignited flue, gypsum quality impact, treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

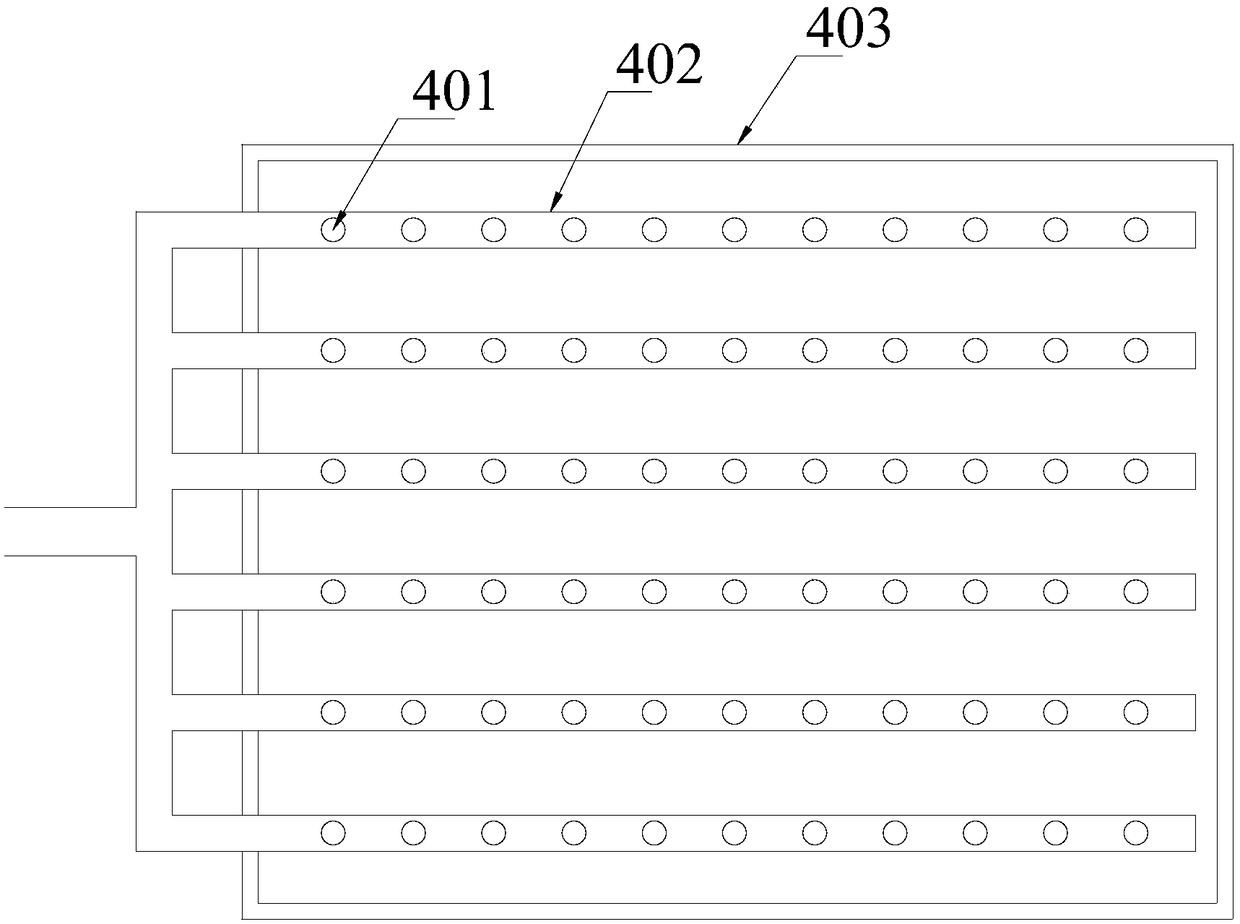

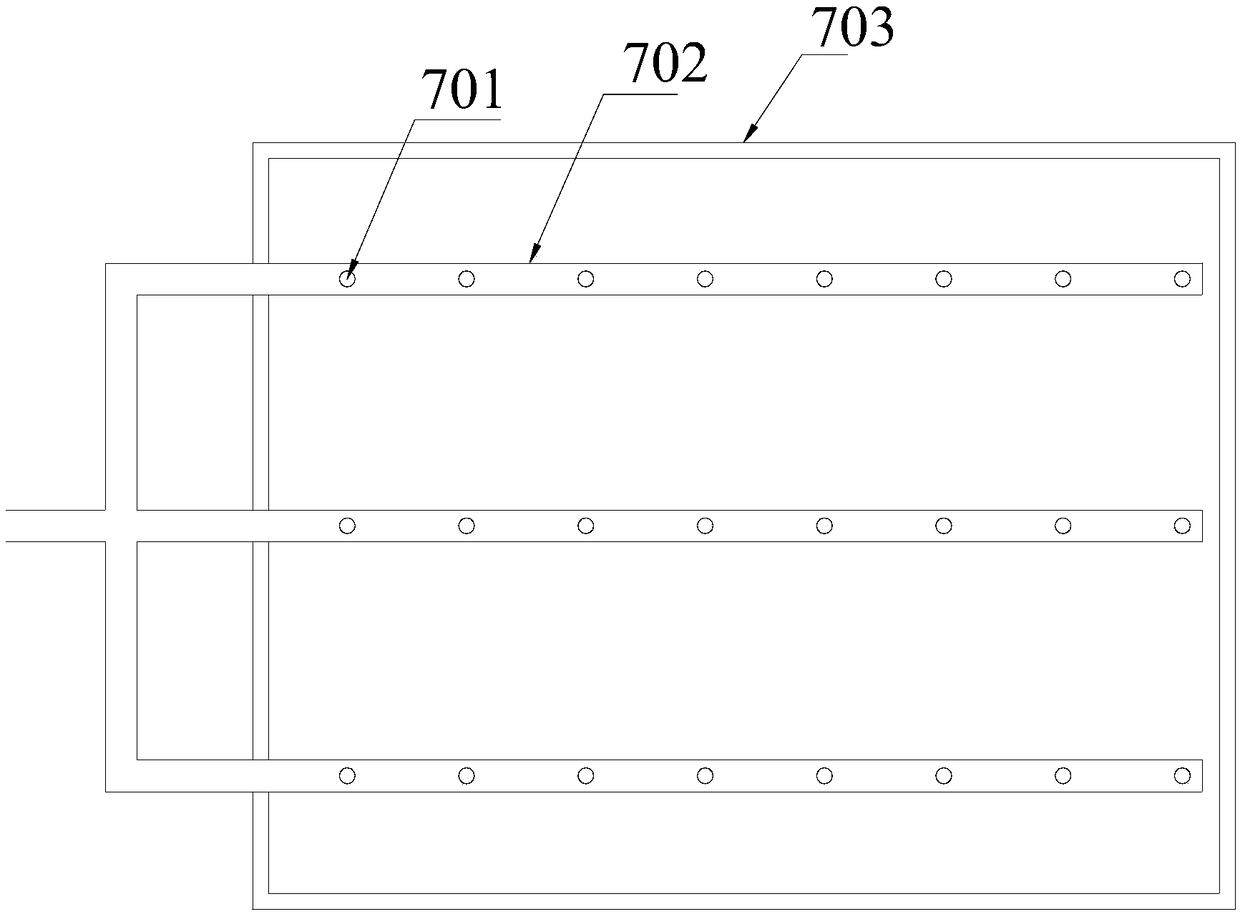

Method used

Image

Examples

Embodiment 1

[0124] The flue gas volume of a coal-fired boiler is 59723m3 / h, NOx349mg / Nm 3 , SO 2 1501mg / Nm 3 After the initial flue gas enters the wet desulfurization and denitrification and wastewater treatment process, the liquid-gas ratio of wastewater to flue gas in the wastewater evaporation cooling section is 0.02L / m 3 , the rapping period of the mist eliminator is 30s, the atomized particle size D50 is 60 μm; the molar ratio of the ozone injected into the flue gas in the oxidation section to the nitrogen oxides in the flue gas is n O3 :n NO =2.5; the supergravity level of the supergravity device in the supergravity absorption section is 500, and the liquid-gas ratio is 5L / m 3, the pH value of the desulfurization and denitrification absorbent circulation tank is 8; in the wastewater oxidation and denitrification section, the amount of sulfite and the amount of oxidizing air are 3mol / m 3 , the added denitrification agent n 氨基磺酸 :n 亚硝酸根 = 2.0. Export NOx9mg / Nm after this proces...

Embodiment 2

[0126] The flue gas volume of a coal-fired boiler is 61723m3 / h, NOx365mg / Nm 3 , SO 2 1461mg / Nm 3 After the initial flue gas enters the wet desulfurization and denitrification and wastewater treatment process, the liquid-gas ratio of wastewater to flue gas in the wastewater evaporation cooling section is 0.01L / m 3 , the rapping cycle of the demister is 130s, the atomized particle size D50 is 120 μm; the molar ratio of ozone injected into the flue gas in the oxidation section to nitrogen oxides in the flue gas is n O3 :n NO =1.5; the supergravity level of the supergravity device in the supergravity absorption section is 300, and the liquid-gas ratio is 4L / m 3 , the pH value of the desulfurization and denitrification absorbent circulation tank is 7; in the wastewater oxidation and denitrification section, the amount of sulfite and the amount of oxidizing air are 6mol / m 3 , the added denitrification agent n 氨基磺酸 :n 亚硝酸根 = 1.5. Export NOx12mg / Nm after this process 3 , SO 2...

Embodiment 3

[0128] The flue gas volume of a coal-fired boiler is 57723m3 / h, NOx333mg / Nm 3 , SO 2 1601mg / Nm 3 After the initial flue gas enters the wet desulfurization and denitrification and wastewater treatment process, the liquid-gas ratio of wastewater to flue gas in the wastewater evaporation cooling section is 0.015L / m 3 , the rapping cycle of the demister is 200s, the atomized particle size D50 is 300μm; the molar ratio of the ozone injected into the flue gas in the oxidation section to the nitrogen oxides in the flue gas is n O3 : n NO =1.0; the supergravity level of the supergravity device in the supergravity absorption section is 100, and the liquid-gas ratio is 8L / m 3 , the pH value of the desulfurization and denitrification absorbent circulation tank is 4; in the waste water oxidation and denitrification section, the amount of sulfite and the amount of oxidizing air are 3mol / m 3 , the added denitrification agent n 氨基磺酸 :n 亚硝酸根 = 1.0. Export NOx11mg / Nm after this process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com