Water suction chamber of multistage centrifugal pump

A water-absorbing chamber and centrifugal pump technology, applied to pumps, parts of pumping devices for elastic fluids, pump components, etc., can solve problems such as prolonged production cycle, insufficient smoothness of the flow channel, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described below in conjunction with the drawings and embodiments.

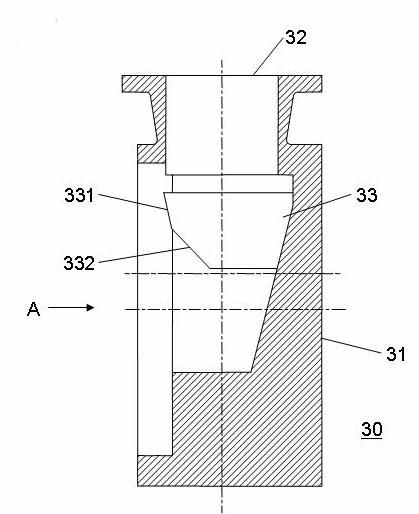

[0021] Please combine image 3 , Figure 5 As shown, the water suction chamber 30 of the multi-stage centrifugal pump of the present invention includes a housing 31, the upper end of the housing 31 is provided with a water inlet 32, and one end of the front end of the housing 31 is connected to the water inlet 1 and communicated with the inlet of the impeller 2. The difference from the prior art is that the suction chamber 30 also includes a baffle 33 that divides the liquid entering the suction chamber 30 into two parts and flows downward. The baffle 33 is arranged in the housing 31 and Located in the middle position above the shaft hole 34 (used to install the impeller shaft 3) in the housing 31. The specific structure of the deflector 33 is as follows: the upper and lower end surfaces of the deflector 33 are curved surfaces, the rear end o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com